Summary –

The article is the story of my new Leica S9I microscope. A few years ago I bought a Leica A60 microscope from Microscope Central. This was truly a game changing event in my engineering life, particularly the soldering part of my life. It is a remarkable instrument… and it is amazing how much better you can see while using it. If you have been following my articles, I am sure that you have seen it in the background of some of the pictures. The only thing that I really really wished that it had was a camera. It turns out that Leica never intended for it to have a camera, and in fact there is no good way to attach one.

A couple of week ago, I started talking with a friend who is getting into electronics about it. As I talked about the features etc, I started really wishing that I had a camera. So I did a little bit of research and realized that Microscope Central had developed a camera attachment for the A60. But after I talked with them about it, I didn’t really feel like it was a good solution for me as it attached over the eye pieces. But it turns out that since I bought the Leica A60S, Leica had developed a new instrument called the Leica S9I (I stands for integrated camera).

Unboxing the Leica S9I

I couldn’t take not having a camera on my A60S, so I pulled the trigger and bought a Leica S9I. And lookey here what I got from the nice UPS man yesterday. I love that Leica Logo.

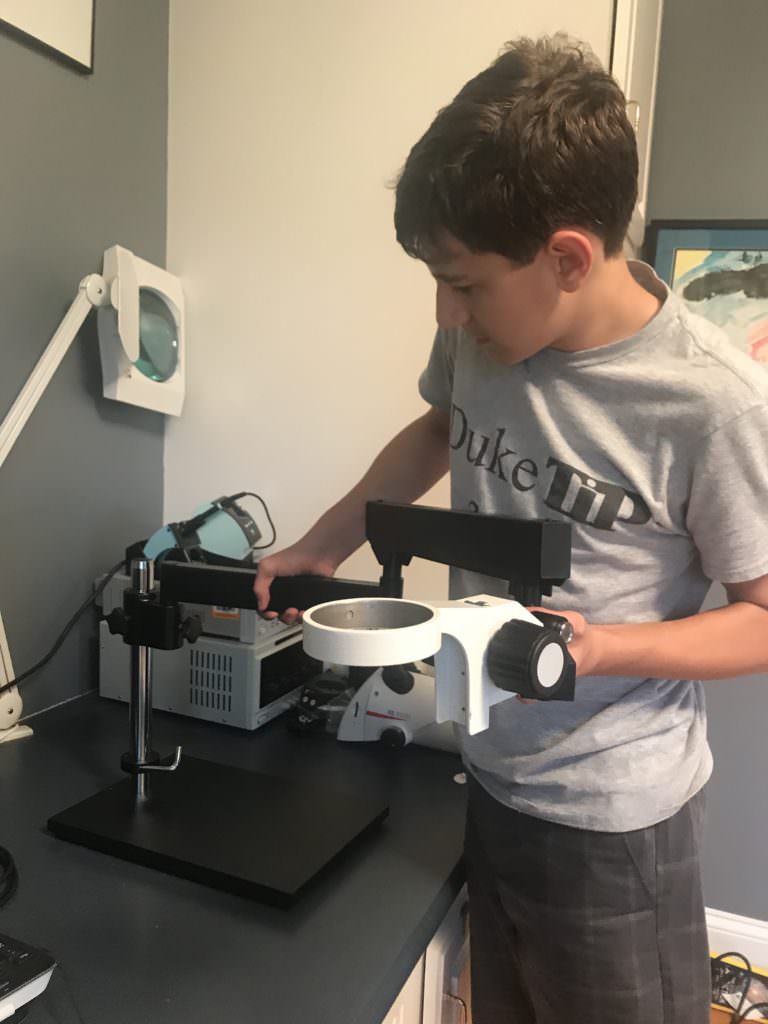

The first thing was to put my Lab assistant Nicholas on the job. Here he is working on the base.

Next, my lab assistant assembles the new telescoping mount – a nice feature that lets me swing the arm and raise and lower the microscope.

After he got the base built he started on the Leica S9I microscope itself.

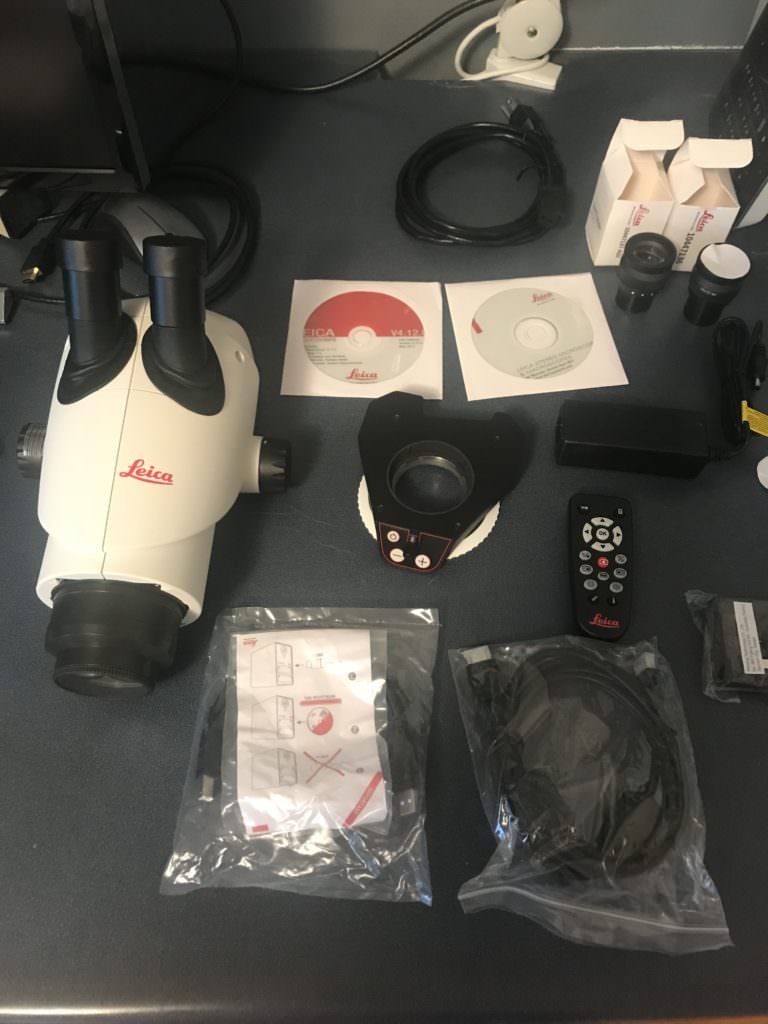

Here is the stuff that came in the box.

- The Leica S9I microscope

- Two eye pieces (one fixed and one focusing)

- A remote control for the integrated Camera

- A bad ass LED light

- USB and HDMI cables.

- Power supply

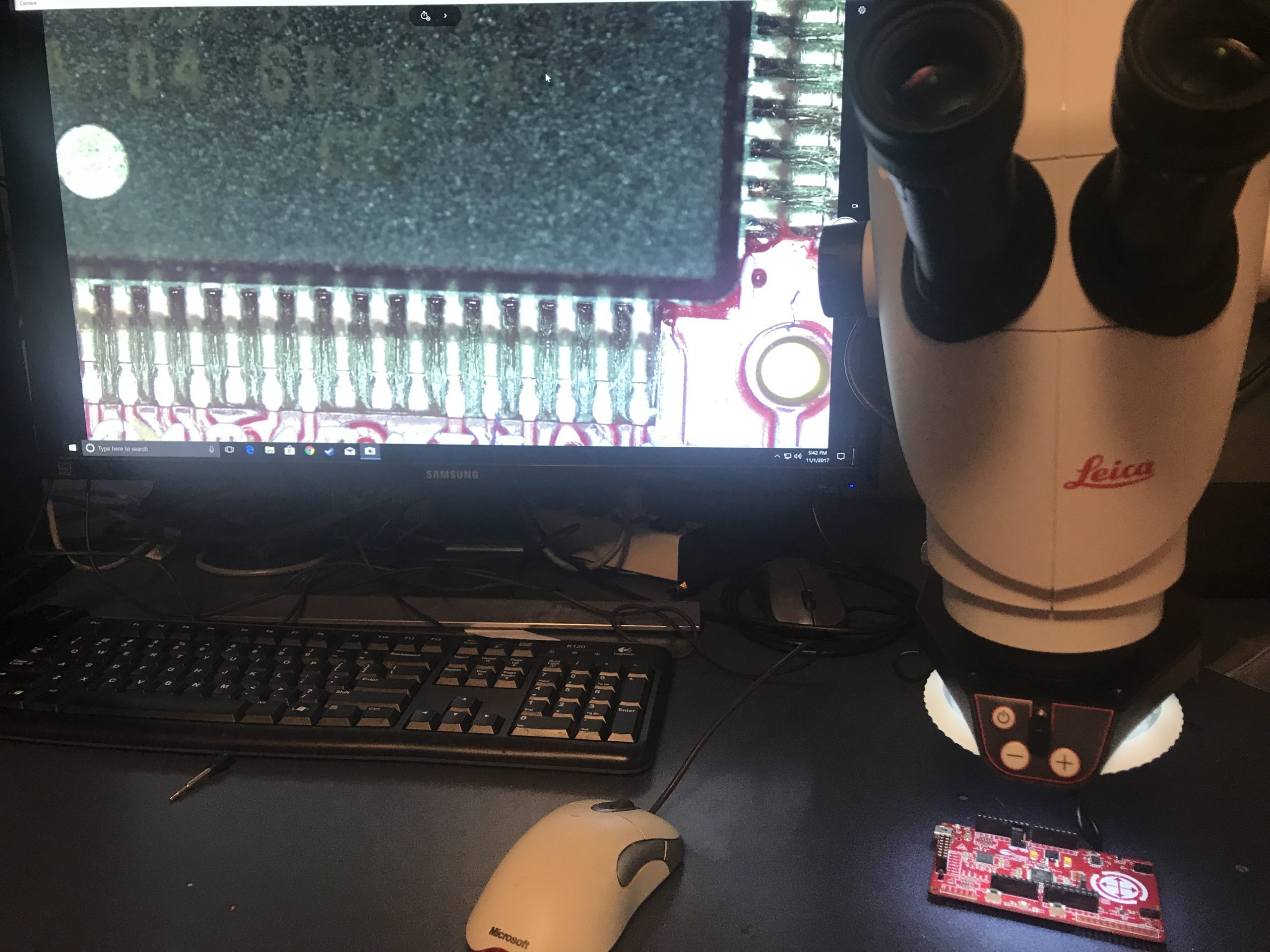

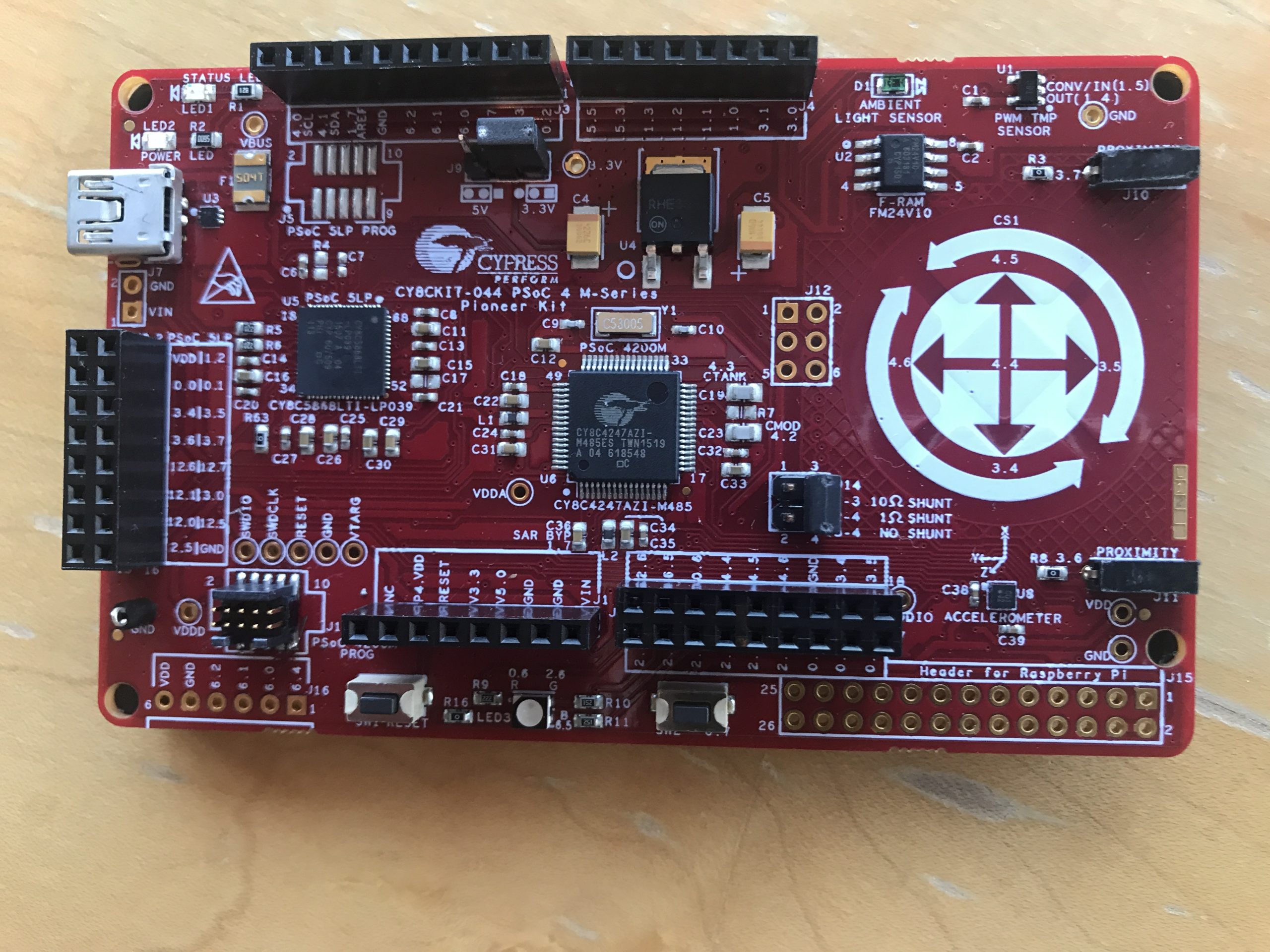

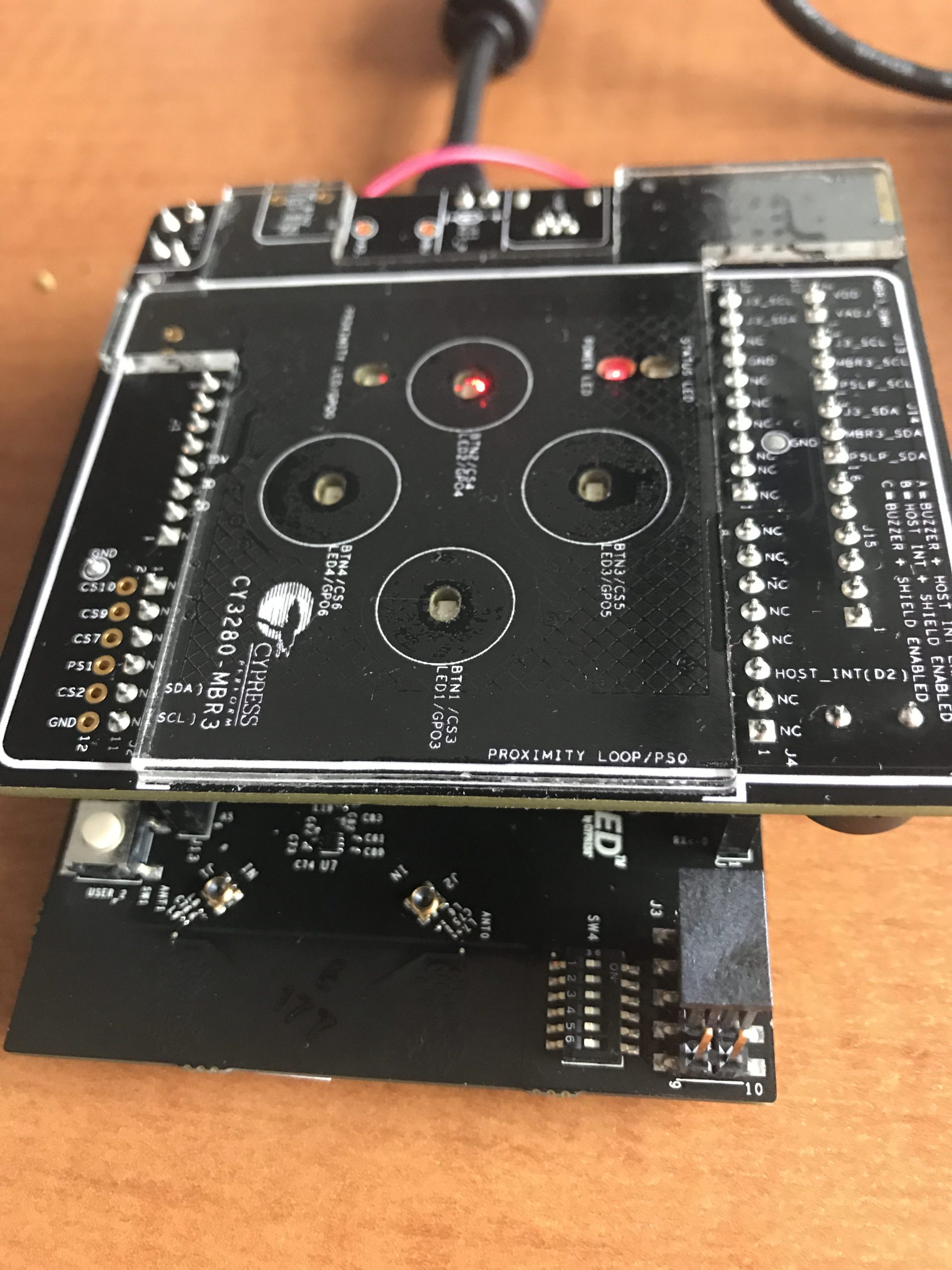

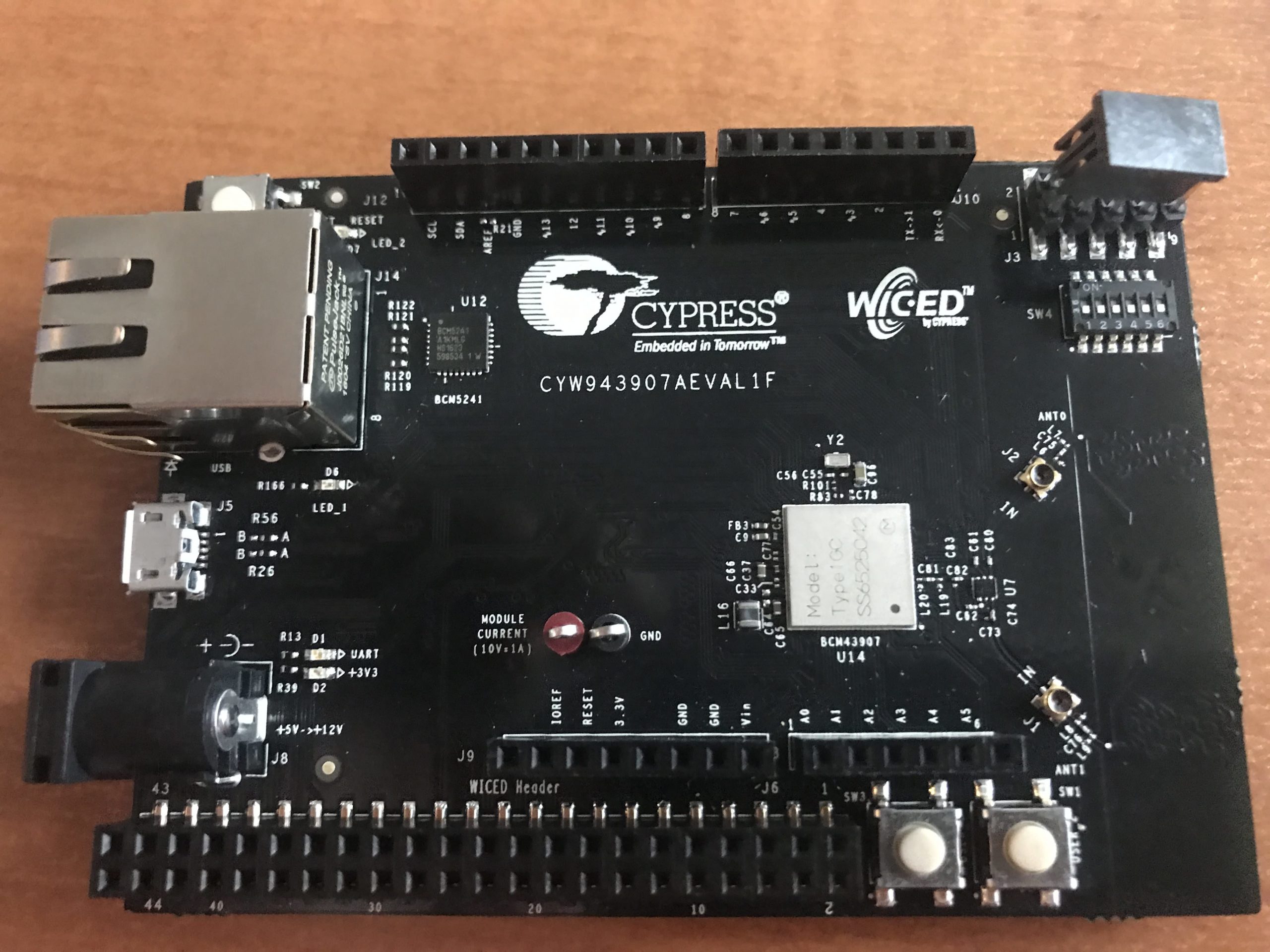

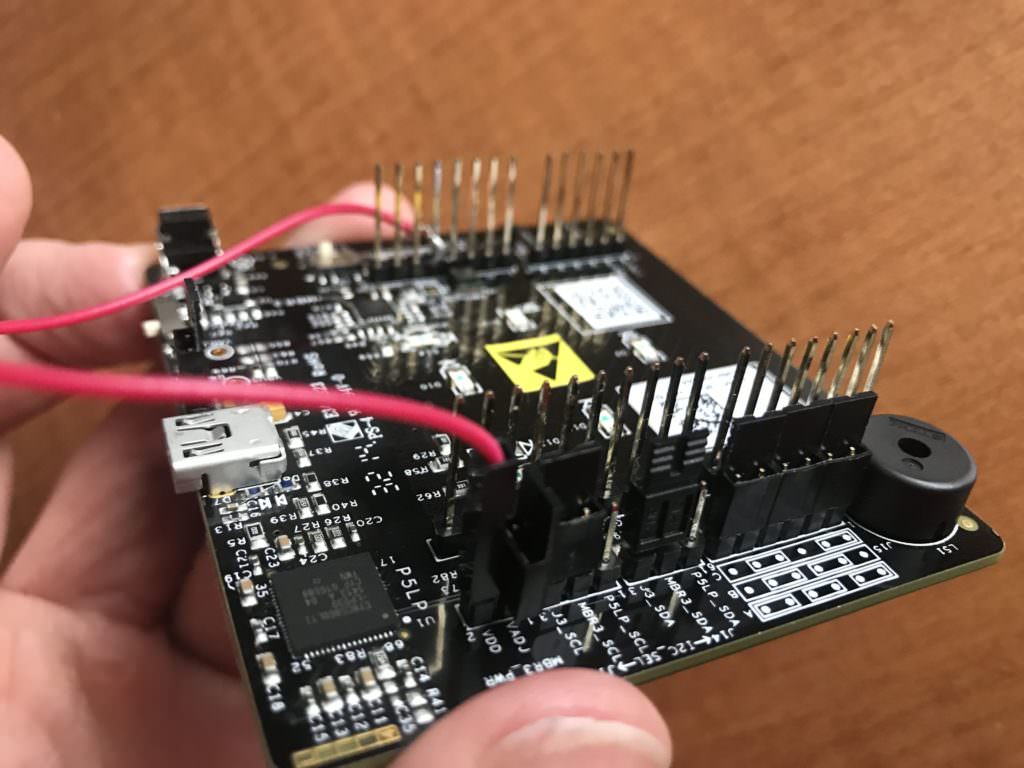

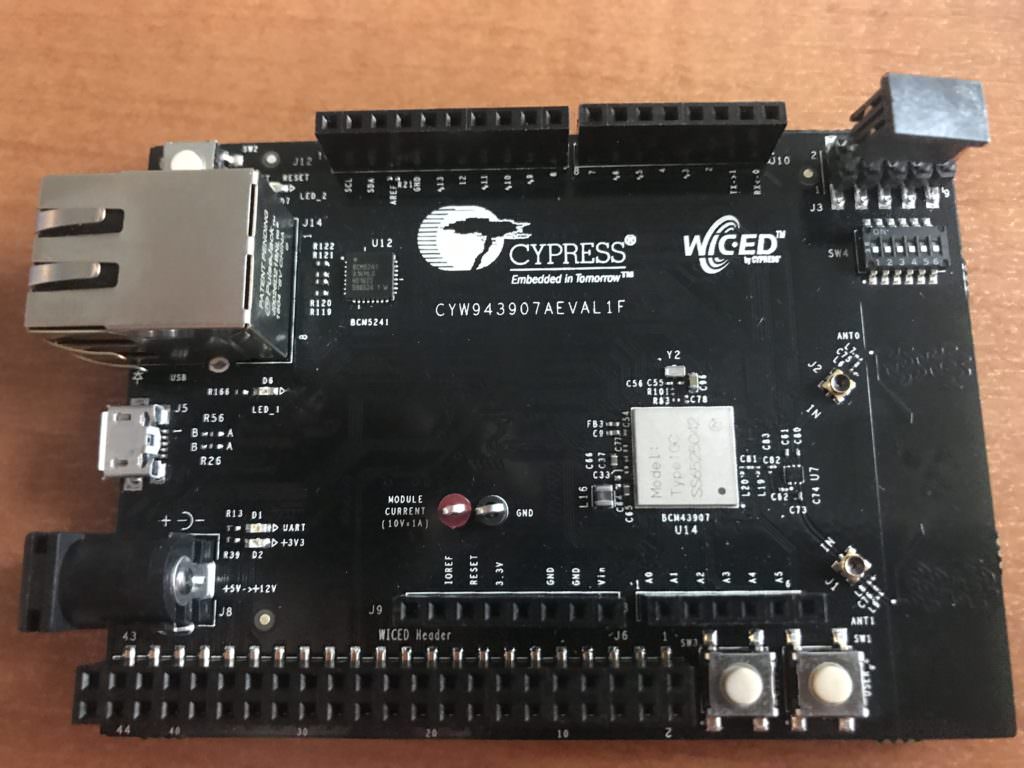

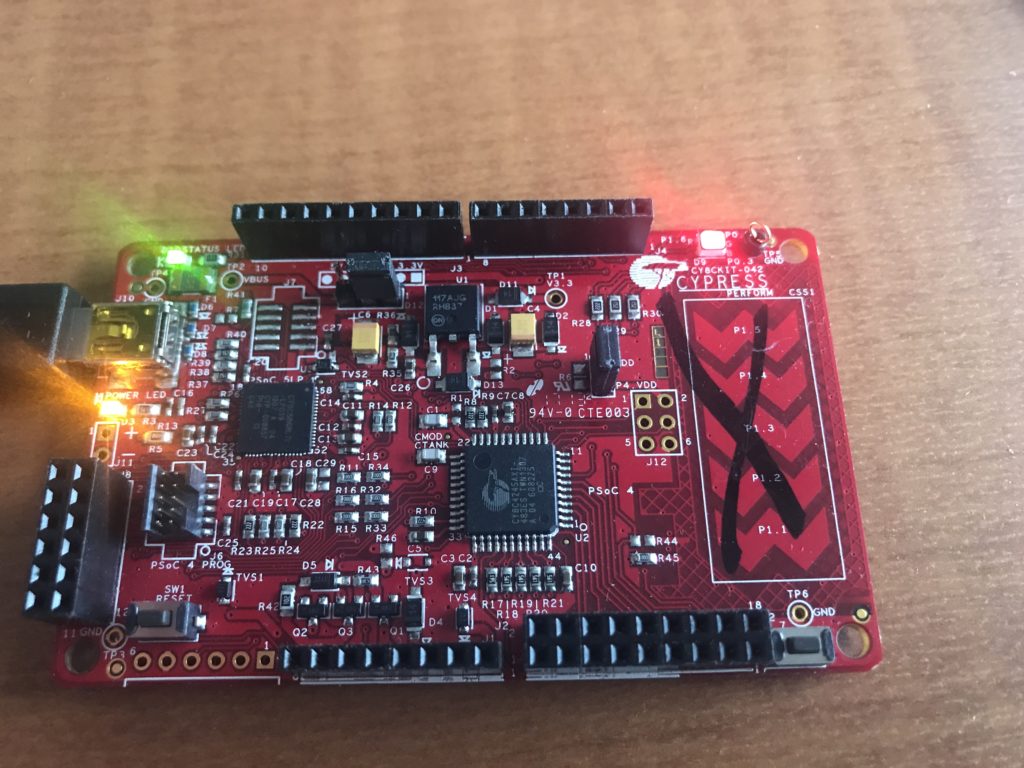

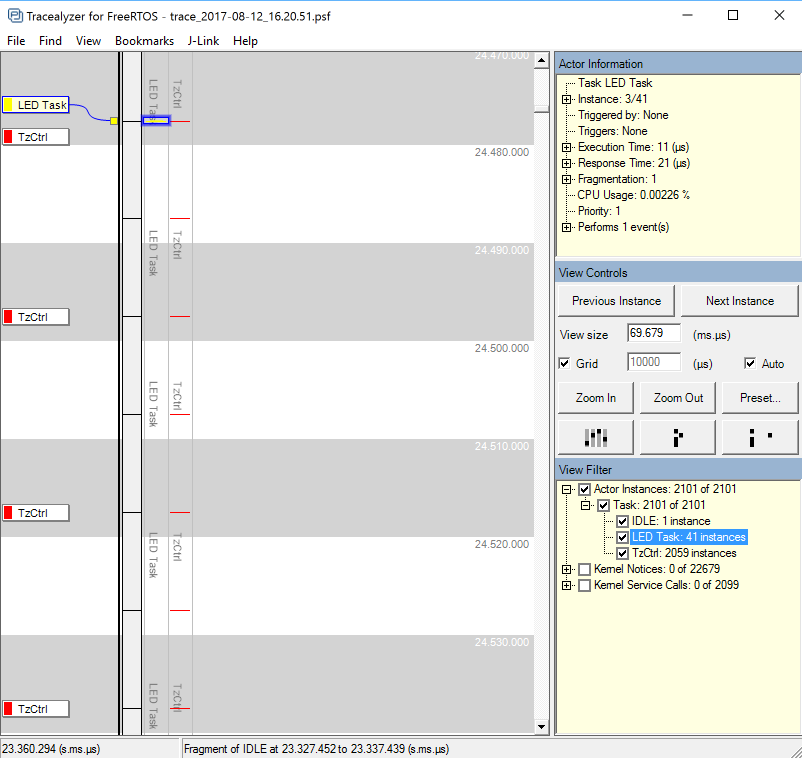

After we (we=Nicholas) got it built he plugged the HDMI cable into the monitor on my desk and took a picture of the setup with the CY8CKIT-044.

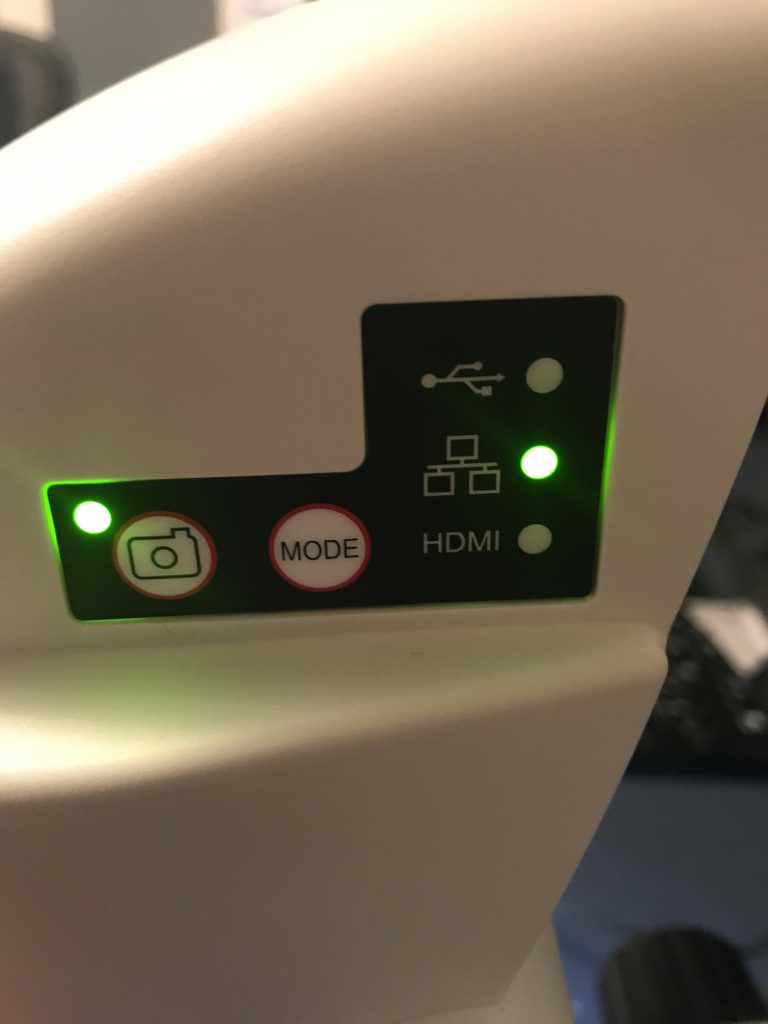

The back of the camera has

- HDMI (to attach to a monitor)

- SD (sd flash card)

- USB (to a computer)

- Ethernet

The side of the camera has

- A power LED (red means booting, green means on)

- Three mode LEDs which show which output is active (Ethernet, USB or HDMI)

- A mode button (to switch between Ethernet, USB and HDMI)

- A take picture button

Leica S9I Software

If you plug in Ethernet then you can control the camera with:

- A Mac OS Application called Leica Acquire

- An iOS Application called Leica Airlab

- A PC Application called Leica Application Suite

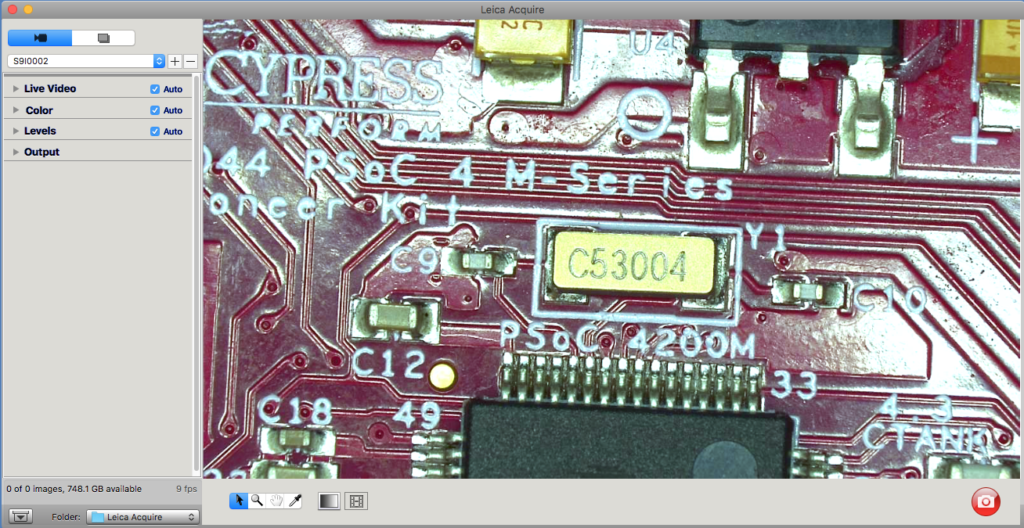

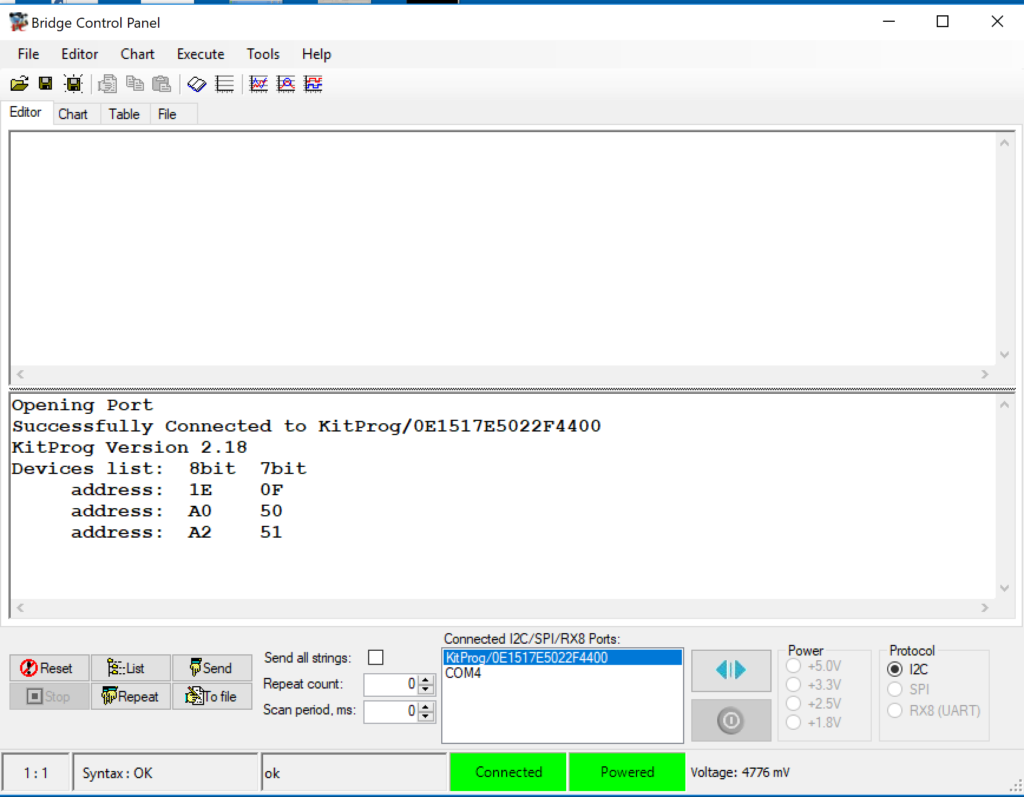

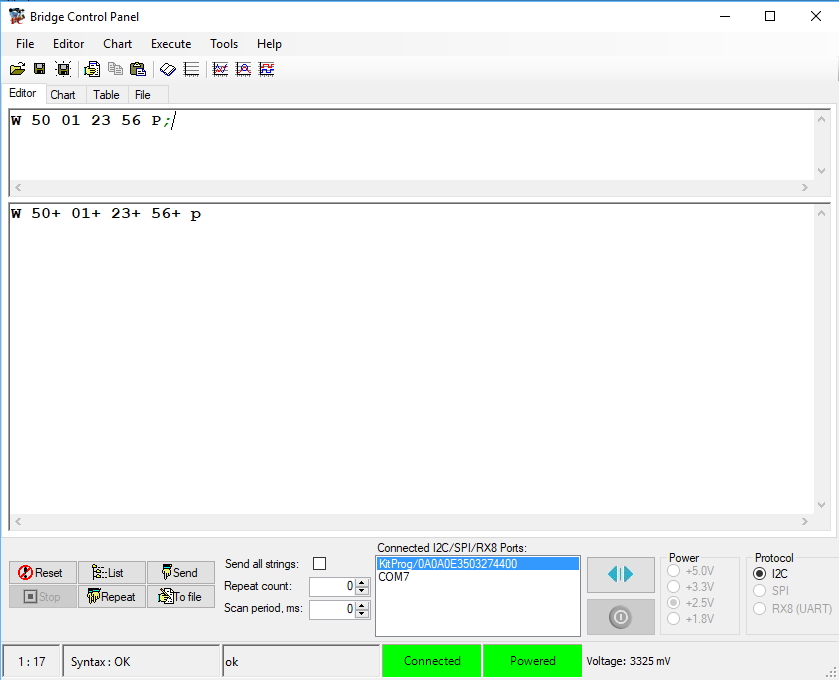

Here are a couple of screenshots of the Leica Acquire Application. There is really not much going on with the application. Basically you can adjust the camera settings and capture video and images. That being said, I am not sure what else you might want to do.

And zoomed in:

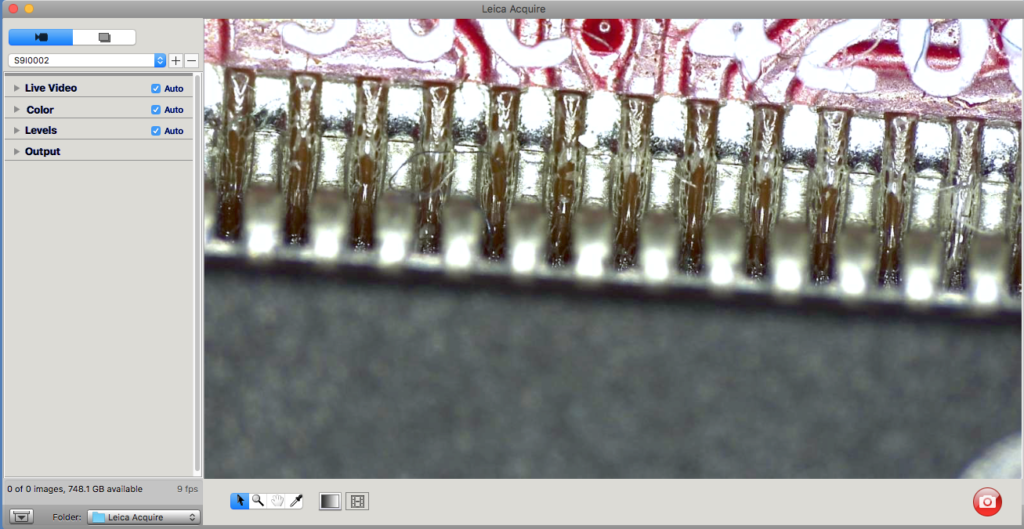

And here is the shot when I clicked the camera button (not a screenshot but an acquired image)

Here are two screenshots of the iOS App. The first is of the image library in the App.

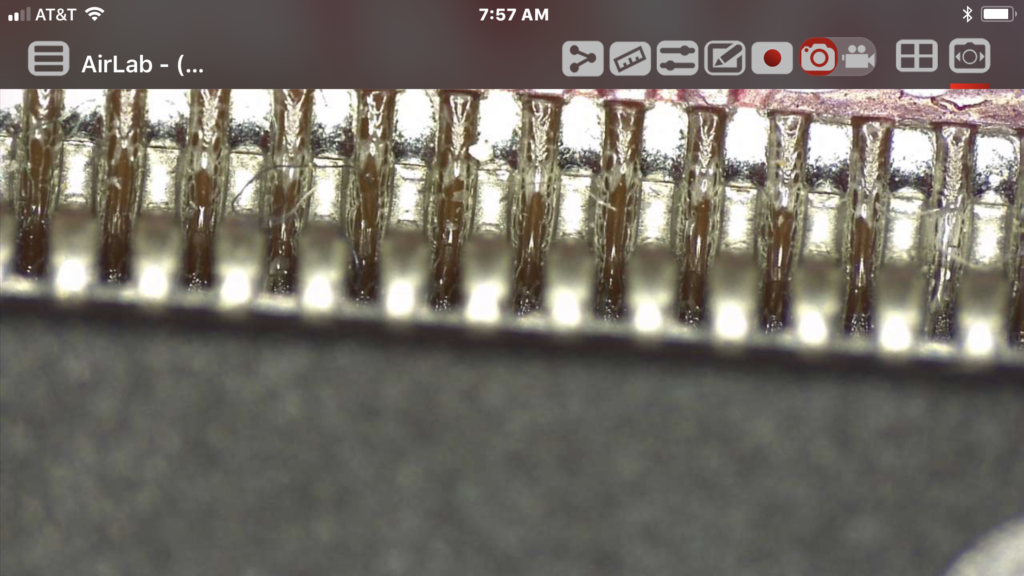

This one is screenshot of the “live” view. One thing that I am not in love with is the icons on the top of the screen are a bit awkward to use. But once I got the hang of them it was OK.

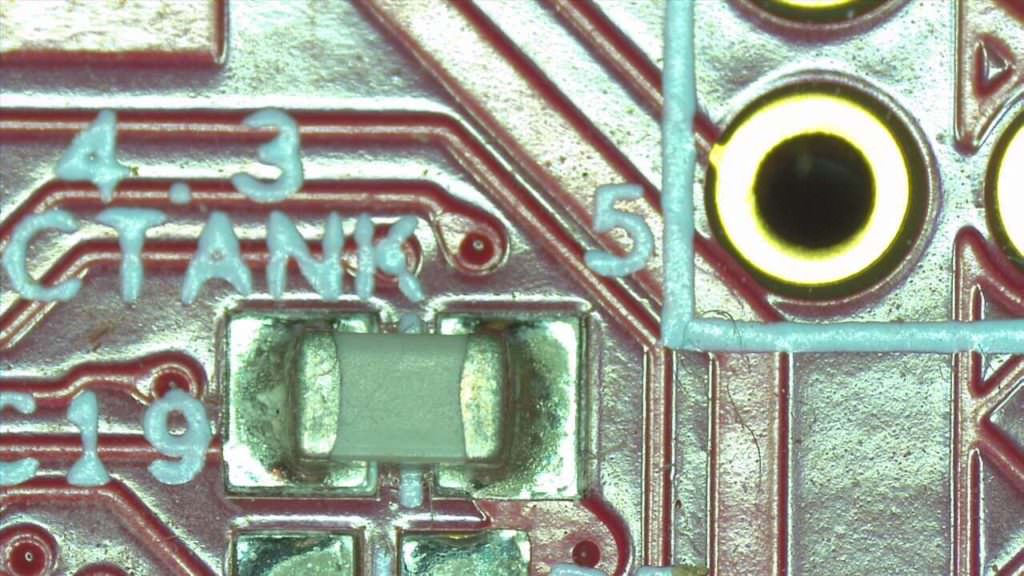

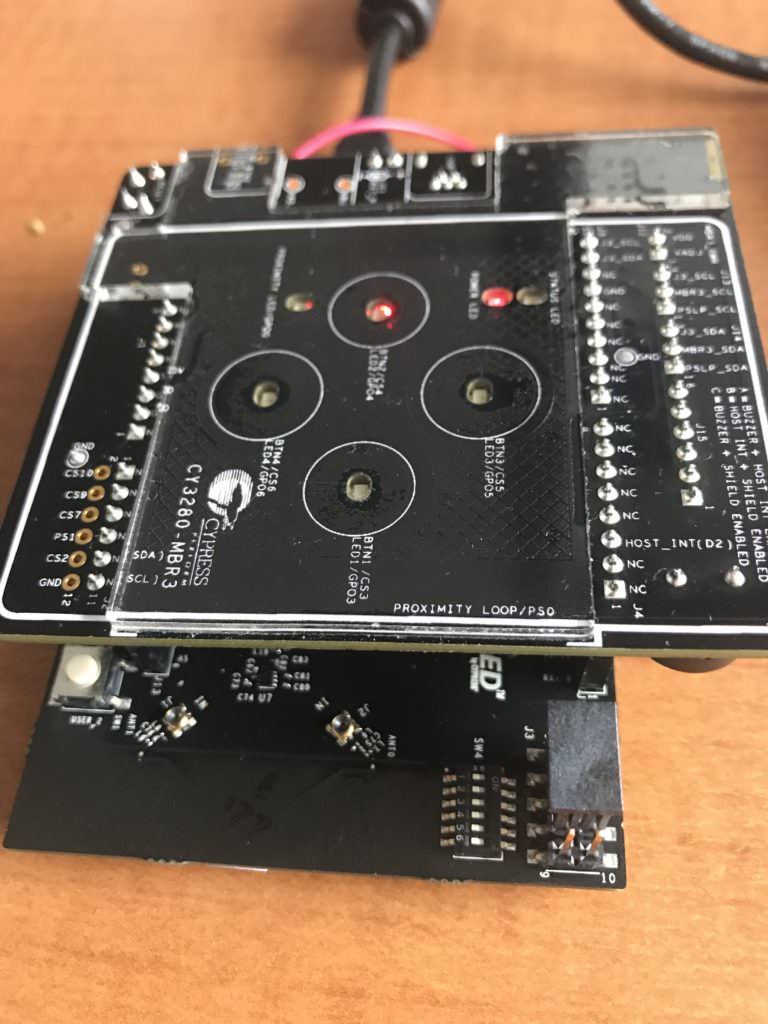

Here is a picture that I took in the iOS App of zoomed in section of the CY8CKIT-044

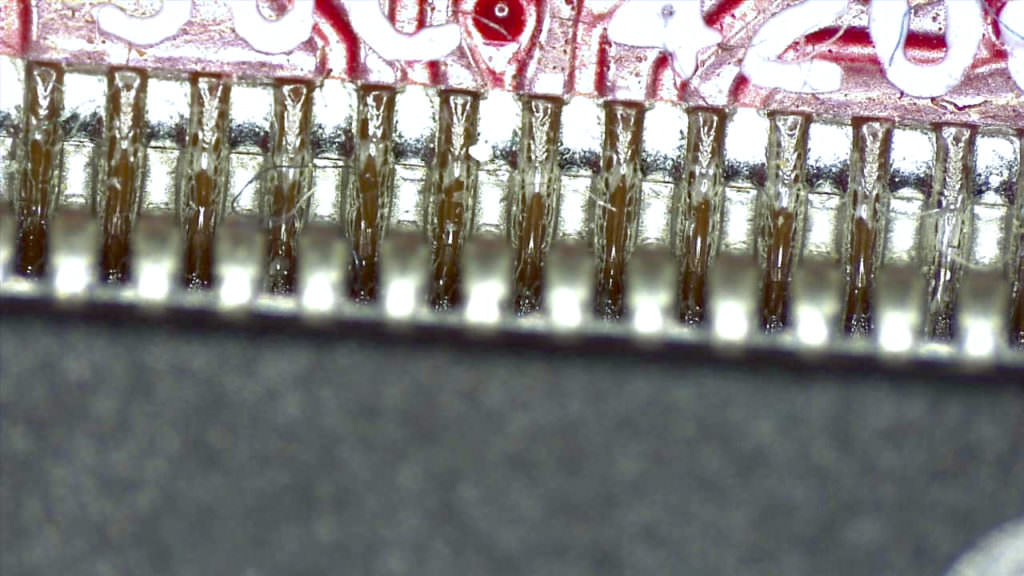

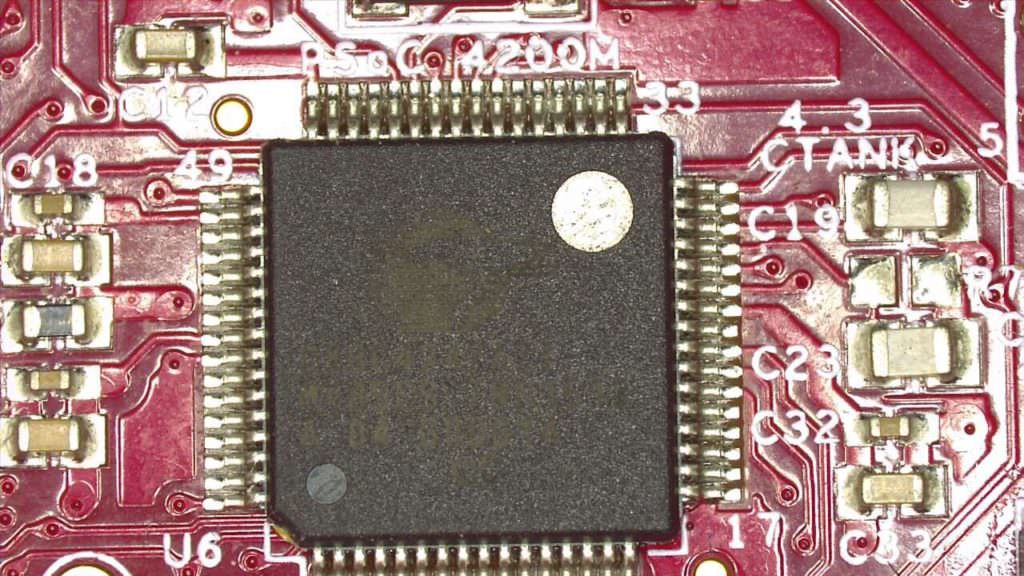

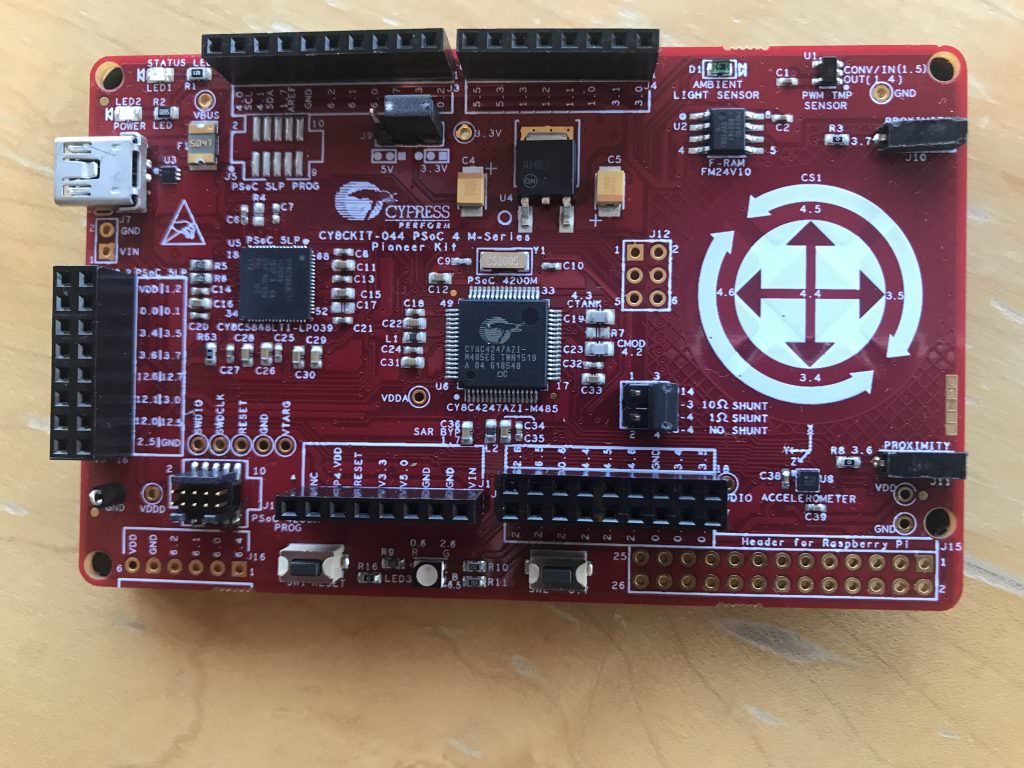

Here is are two pictures that I took with the iOS App. The first is with the Development Kit flat on my desk, and the 2nd with the Development Kit tilted so you can read the laser mark on the CY8C4247AZI-M485.

It took a little bit of time to get my eyeballs and the camera settings in sync. Which was a bit annoying as the only thing that I can say that I don’t like about the Leica S9I is the stupid IR remote control for the camera sucks. The sucky remote control makes it a pain in the neck to get the camera menus configured. I think that it is too bad that they didn’t put a Cypress Bluetooth device into the camera so that the system would work better.

All that being said. Leica has always been the leader in optics, and based on my experience with this microscope, that leadership will continue far into the future. One of the great things about this (and the A60) microscope is the Leica Fusion Optics. The Leica engineers used an optical trick that is possible because the microscope is binocular. We all remember from physics class that numerical aperture and magnification are intertwined to set resolution and depth of field. Moreover, there is a tradeoff between numerical aperture and depth of field. For soldering you want to have a super sharp image, and a big depth of field. What Leica Fusion Optics does is present your eyes with two different images. One that is super sharp, but with limited depth of field. And the other that is less sharp but with more depth of field. Then your brain magically combines them into one image that appear to have a giant amount of sharp depth of field. You can read more about it on the Leica Microscope website.

Microscope Central

My final note in this whole thing is about Microscope Central. Both times I looked for Microscopes I ended up buying from them. This is a family owned business in Pennsylvania which made the transition to online at some point. The first time I clicked on the little “online chat” button at the bottom of the screen it was a holiday Saturday and one of the Miller family answered … and was amazingly helpful in getting me on the right track for buying the A60S. This morning I thought I would click there, and Scott Miller was there almost immediately.

This time they were awesome in helping me get switched to the Leica S9I. They spent a bunch of time talking me through optics issues on the industrial microscopes. Moreover he helped me spend money on things that matter.. e.g. Leica glass… but also helped my buy a much less expensive stand, which is very good as well. All in all I find this remarkable because I am hardly a relevant customer, yet the treated me well. I wouldn’t hesitate to buy from them again.