WICED Bluetooth Using the CYW20719

#

Title

Comment

0

A Two Hour WICED Bluetooth Class

WICED Bluetooth Using the CYW20719 in all its glory

1

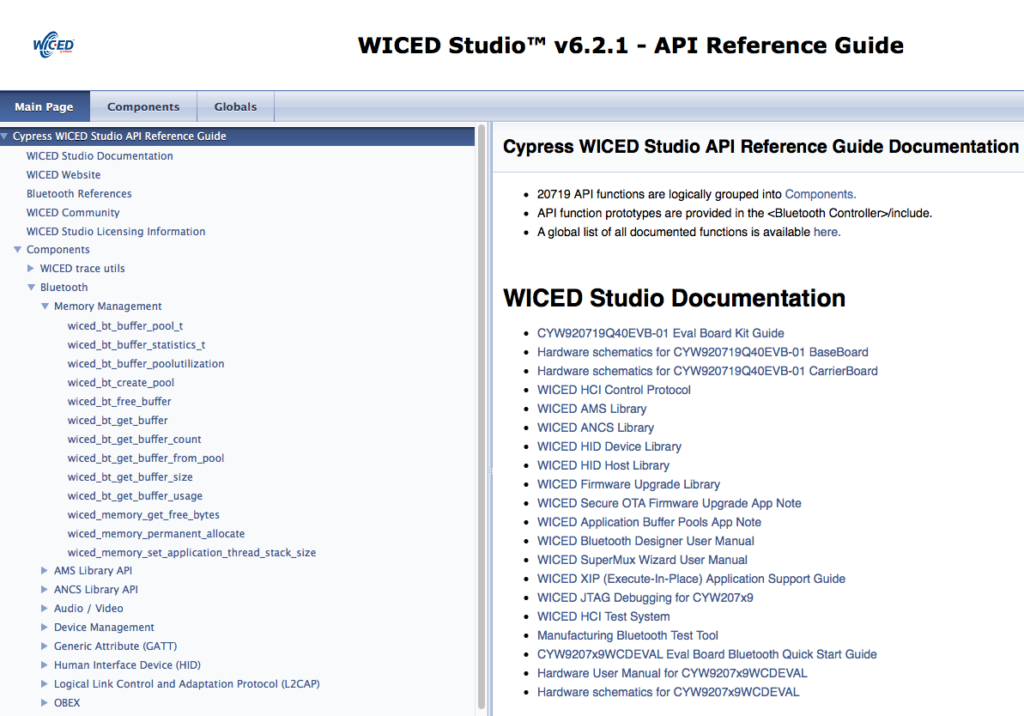

Resources

Links to all of the Cypress WICED information including videos, application notes etc.

2

Your First Project

Making Hello World & the Blinky LED

3

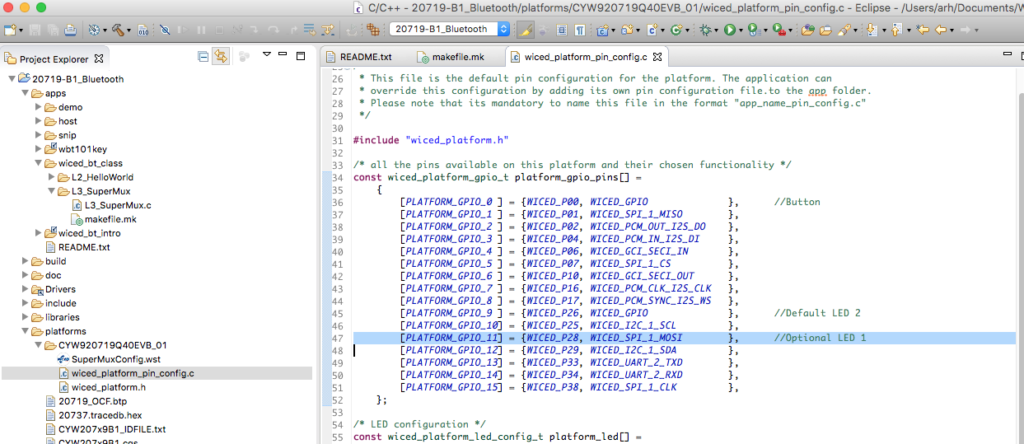

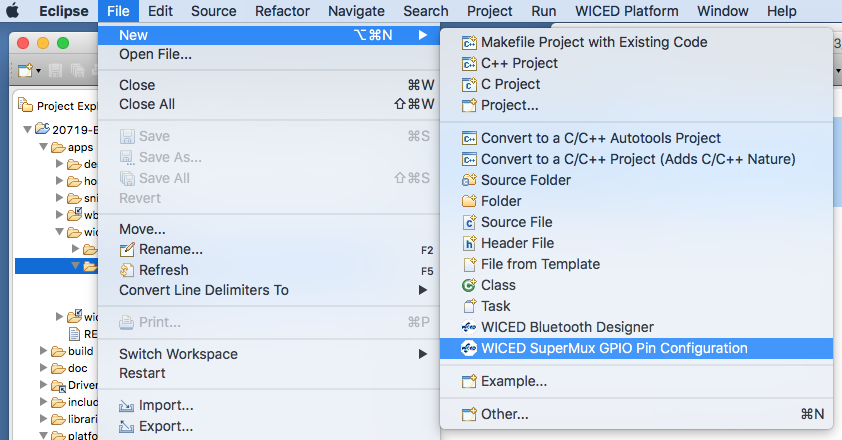

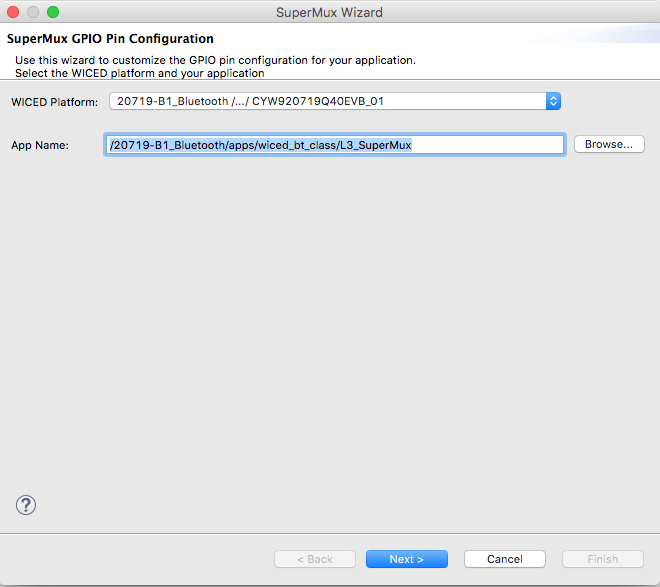

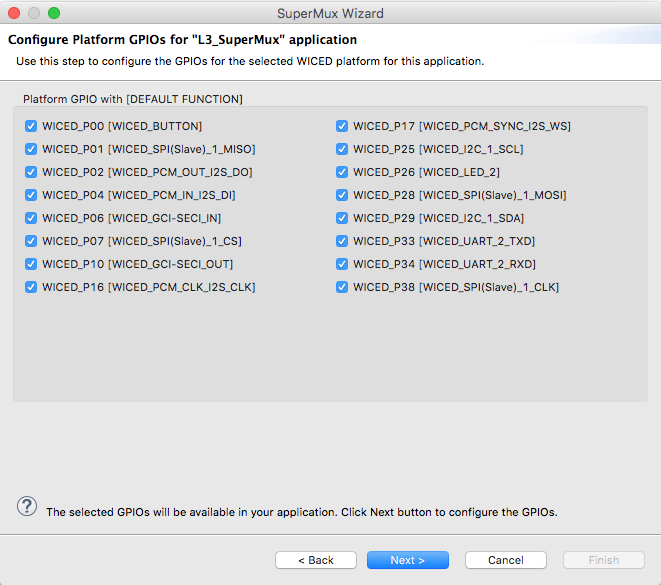

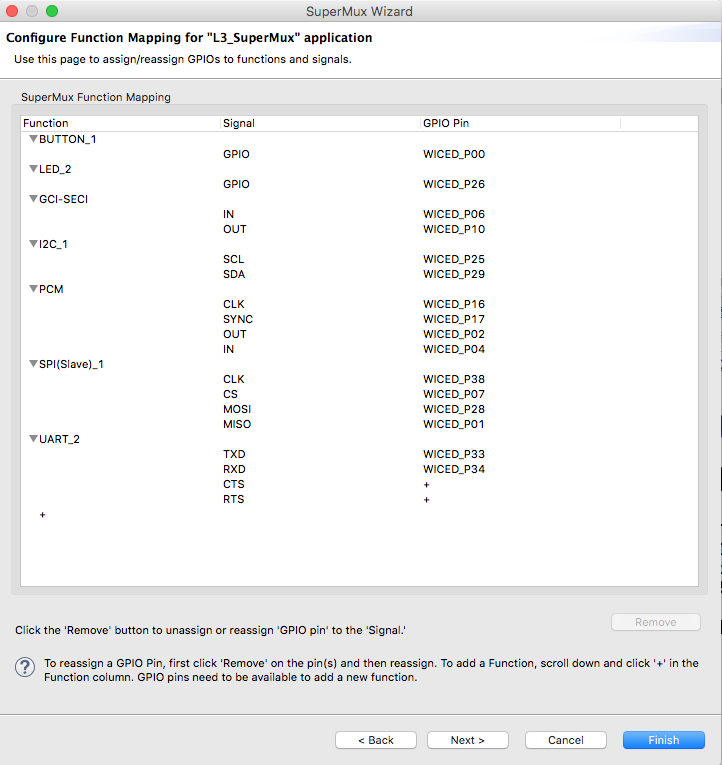

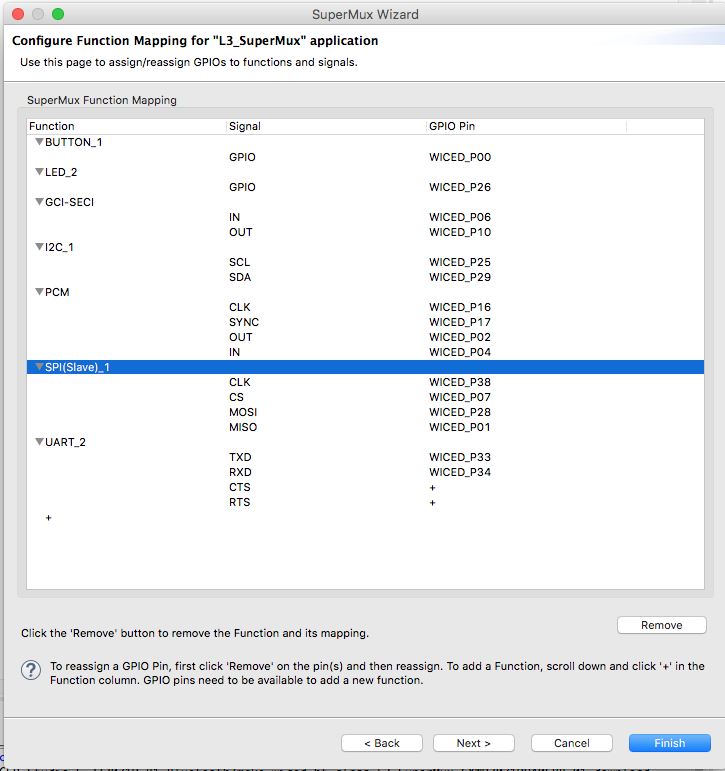

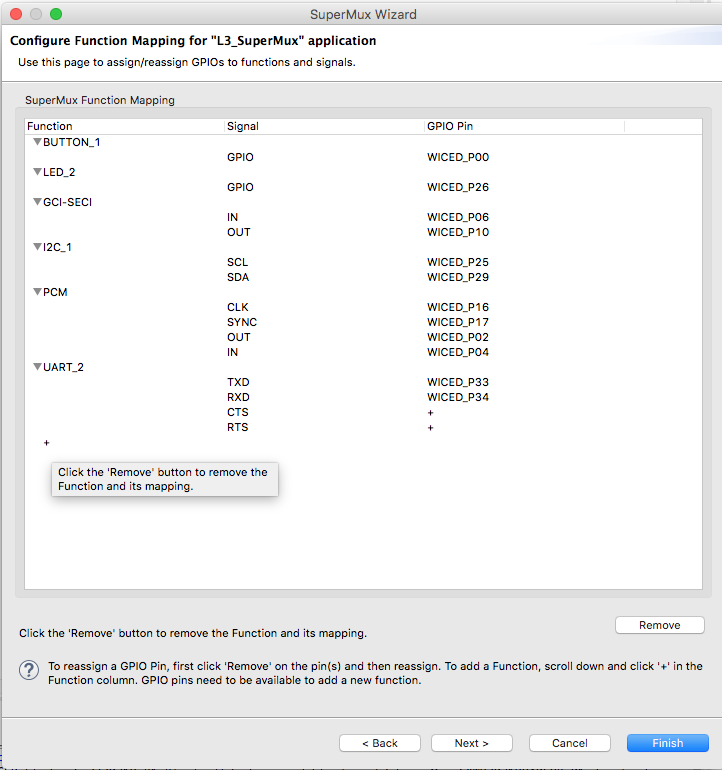

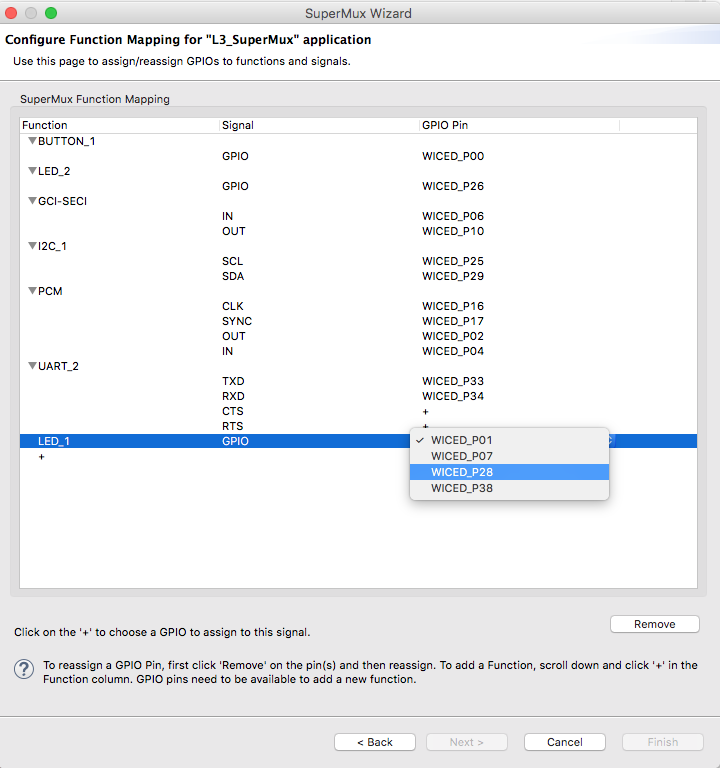

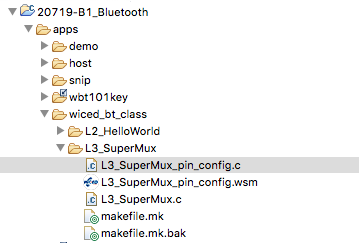

The Super Mux Tool

Learning about platforms and the Super Mux Tool

4

Snips

Using the example projects to learn Bluetooth

5

Bluetooth Designer

Using the tool to customize a project and get going fast

6

The CCCD & Notification

Writing back to the Central

7

Advertising Beacon

Building a beacon project to advertise your custom information

8

Scanner

Viewing the world around you

9

Bluetooth Classic SPP

Using the Serial Port Profile to Transmit Lots of Data

Source code:

- git@github.com:iotexpert/wiced_bt_intro.git

- https://github.com/iotexpert/wiced_bt_intro

Summary

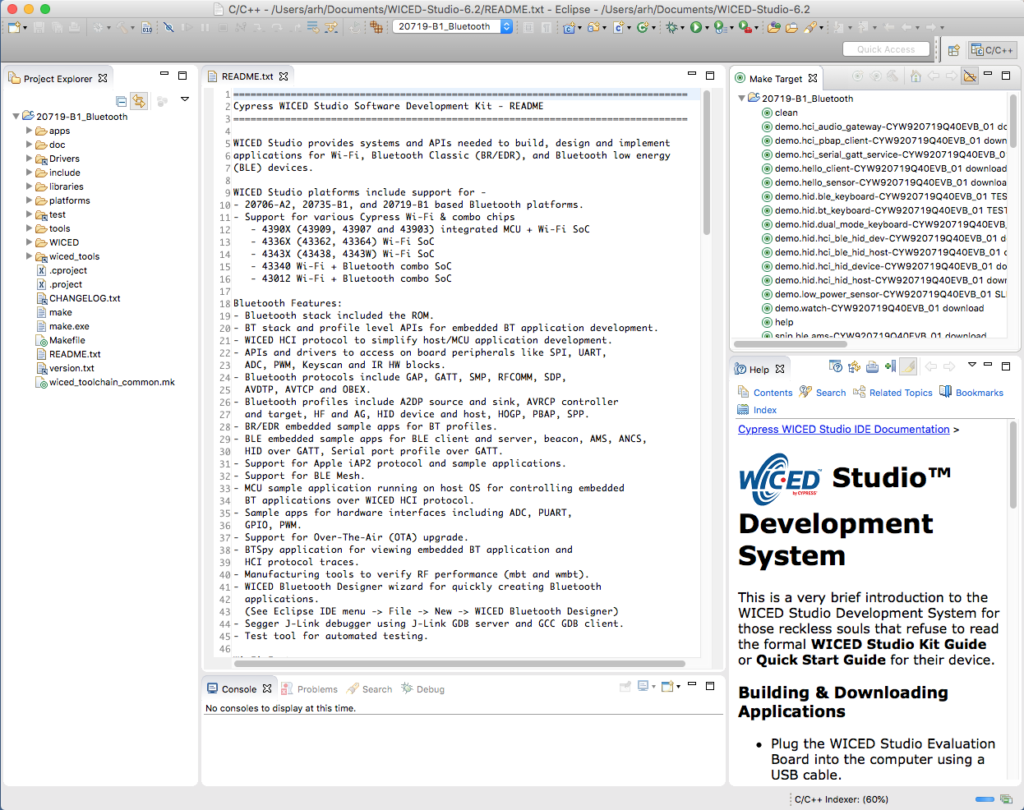

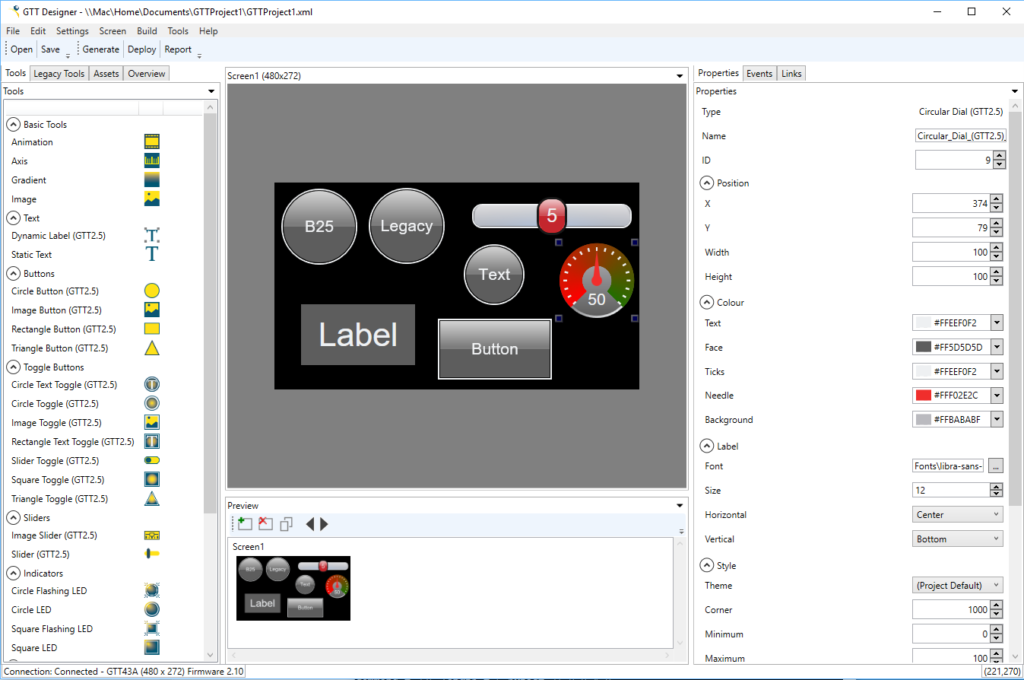

In this lesson I am going to show you how to NOT write all of your own code and still get the job done. In this lesson we are going to do three things.

- Examine & Run the hal_gpio snip

- Examine & Run the hal_i2c_master snip

- Copy the hal_i2c_master snip and make it “more better”

To modify the hal_i2c_master snip I will

- Make a new folder called L4_Accelerometer

- Copy the makefile.mk and hal_i2c_master.c into the L4_Accelerometer folder

- Create a new make target and make sure that things still work

- Look at the LSM9DS1 datasheet

- Update the function initialize_app to startup the Accelerometer and speed up the polling

- Update the function comboread_cb to read the Acceleration registers and print out the values

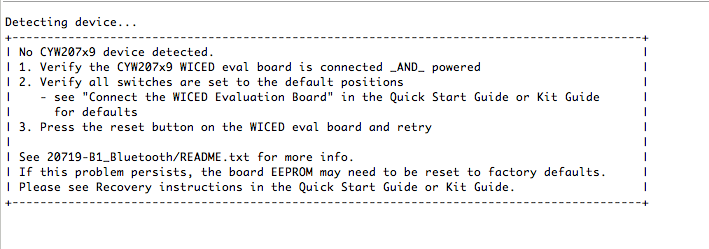

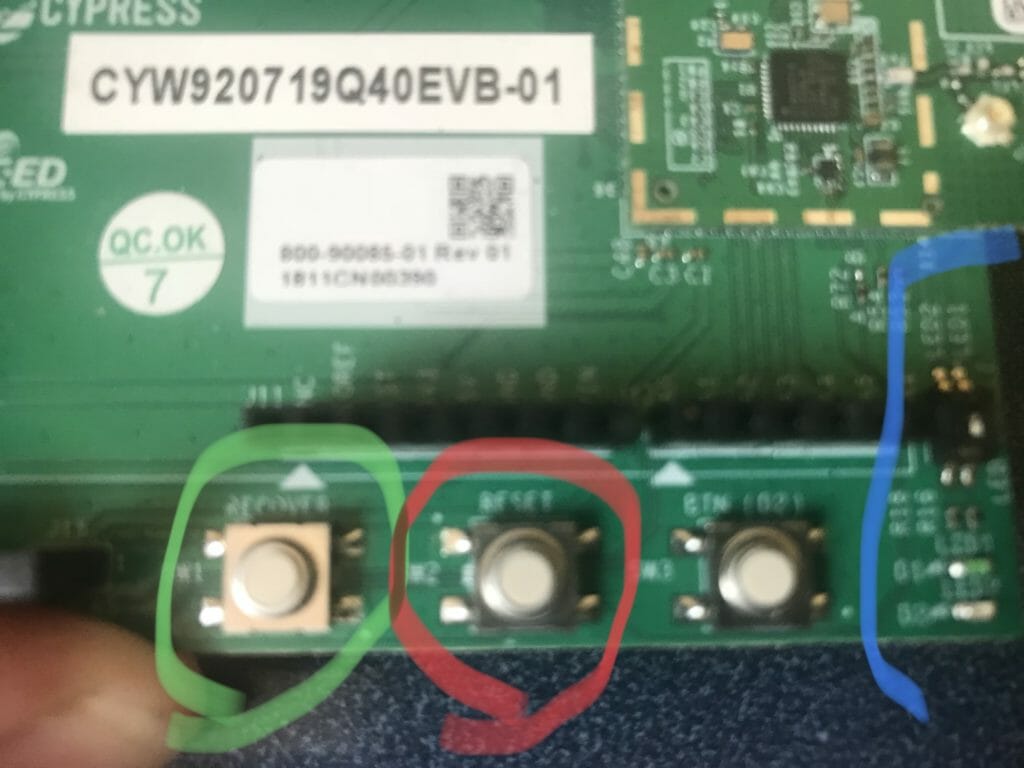

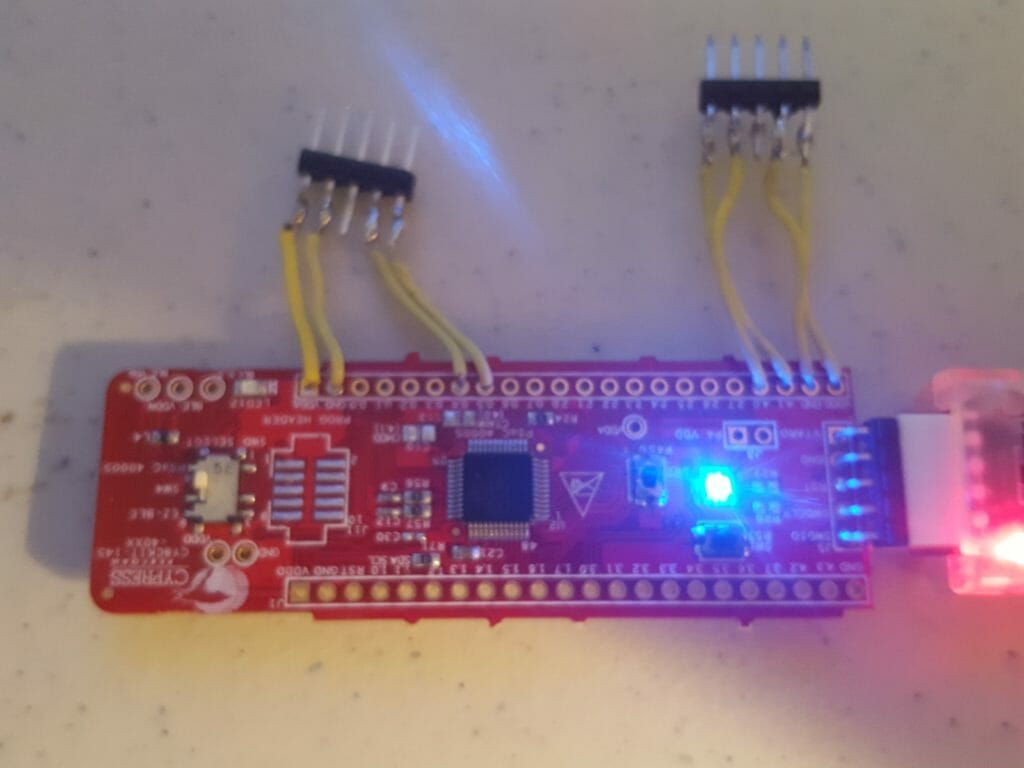

Run hal_gpio

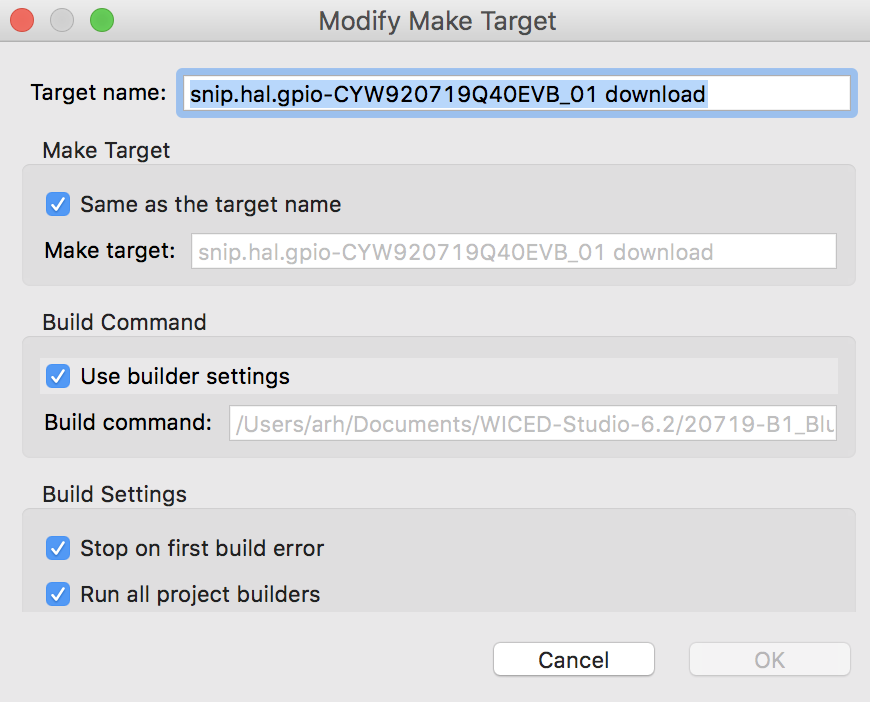

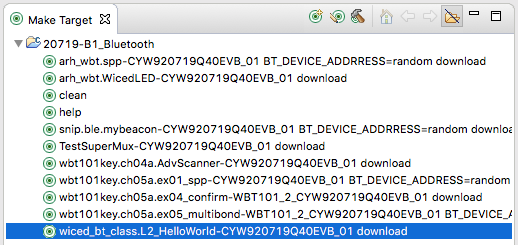

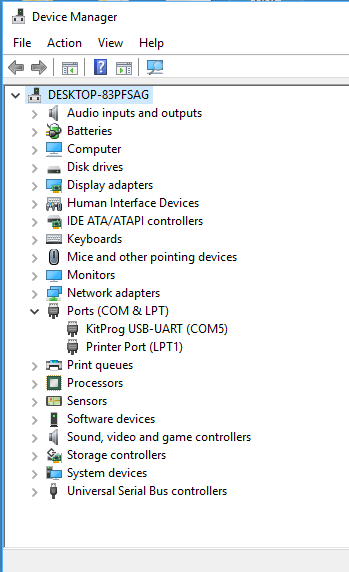

If you dont already have a make target for snip.hal.hal_gpio create one and then program the board.

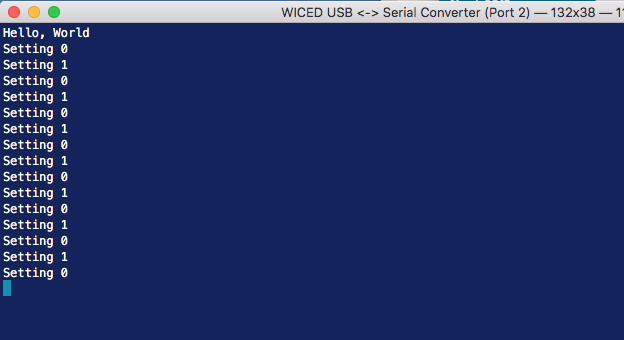

Notice that the light blinking will change speeds if you press the button. Let’s look at the code that does this:

At the beginning it sets up a timer

// Initialize timer to control the pin toggle frequency

if (wiced_init_timer(&hal_gpio_app_timer, &hal_gpio_app_timer_cb, 0, WICED_SECONDS_PERIODIC_TIMER) == WICED_SUCCESS)

{

if (wiced_start_timer(&hal_gpio_app_timer, LED_BLINK_FREQ_A_IN_SECONDS) != WICED_SUCCESS)

{

WICED_BT_TRACE("Seconds Timer Error\n");

}

}

The timer calls this function each time the timer expires.

/*

* The function invoked on timeout of app. seconds timer.

*/

void hal_gpio_app_timer_cb(uint32_t arg)

{

static uint32_t wiced_seconds = 0; /* number of seconds elapsed */

uint8_t index = 0;

wiced_seconds++;

if (wiced_seconds & 1)

{

for (index = 0; index < sizeof(output_pin_list); index++)

{

wiced_hal_gpio_set_pin_output(output_pin_list[index], GPIO_PIN_OUTPUT_LOW);

}

}

else

{

for (index = 0; index < sizeof(output_pin_list); index++)

{

wiced_hal_gpio_set_pin_output(output_pin_list[index], GPIO_PIN_OUTPUT_HIGH);

}

}

}

And when the button is pressed all it does is switch back and forth between two different intervals for the timer. And after the switch it restarts the timer.

/*

* Handle interrupt generated due to change in the GPIO state

*/

void hal_gpio_app_interrrupt_handler(void *data, uint8_t pin)

{

static uint32_t blink_freq = LED_BLINK_FREQ_A_IN_SECONDS;

// toggle LED blink rate upon each button press

if (blink_freq == LED_BLINK_FREQ_A_IN_SECONDS)

{

blink_freq = LED_BLINK_FREQ_B_IN_SECONDS;

}

else

{

blink_freq = LED_BLINK_FREQ_A_IN_SECONDS;

}

if (wiced_stop_timer(&hal_gpio_app_timer) == WICED_SUCCESS)

{

wiced_start_timer(&hal_gpio_app_timer, blink_freq);

}

// clear the interrupt status

wiced_hal_gpio_clear_pin_interrupt_status(pin);

}

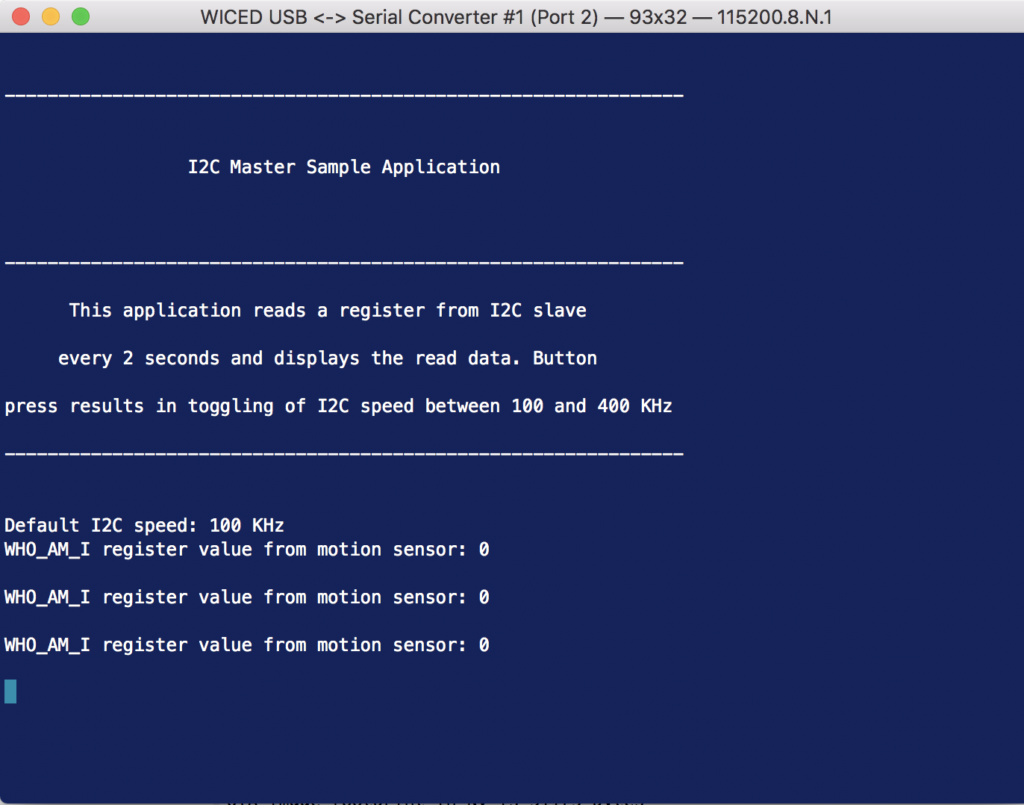

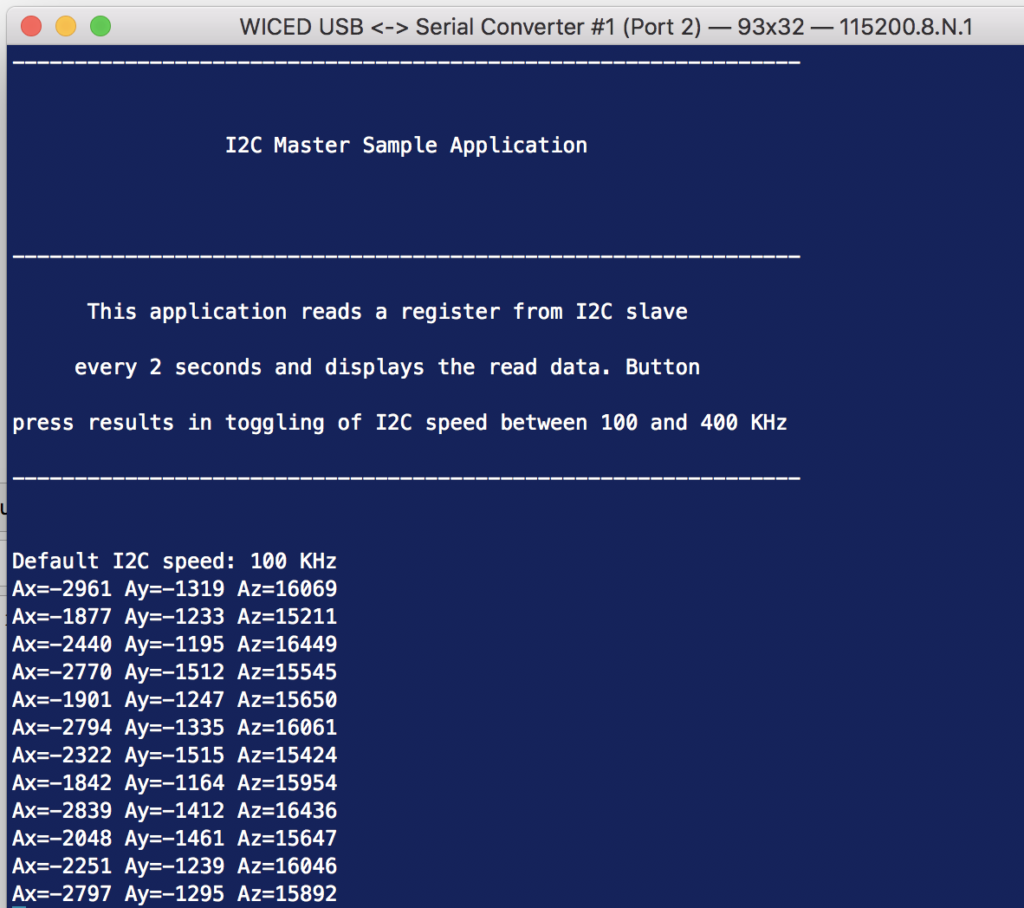

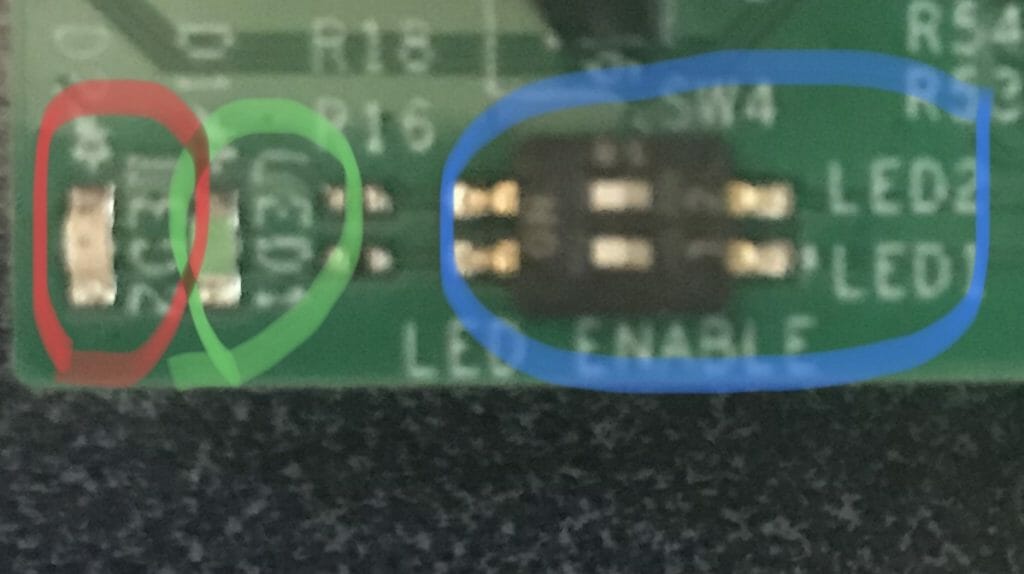

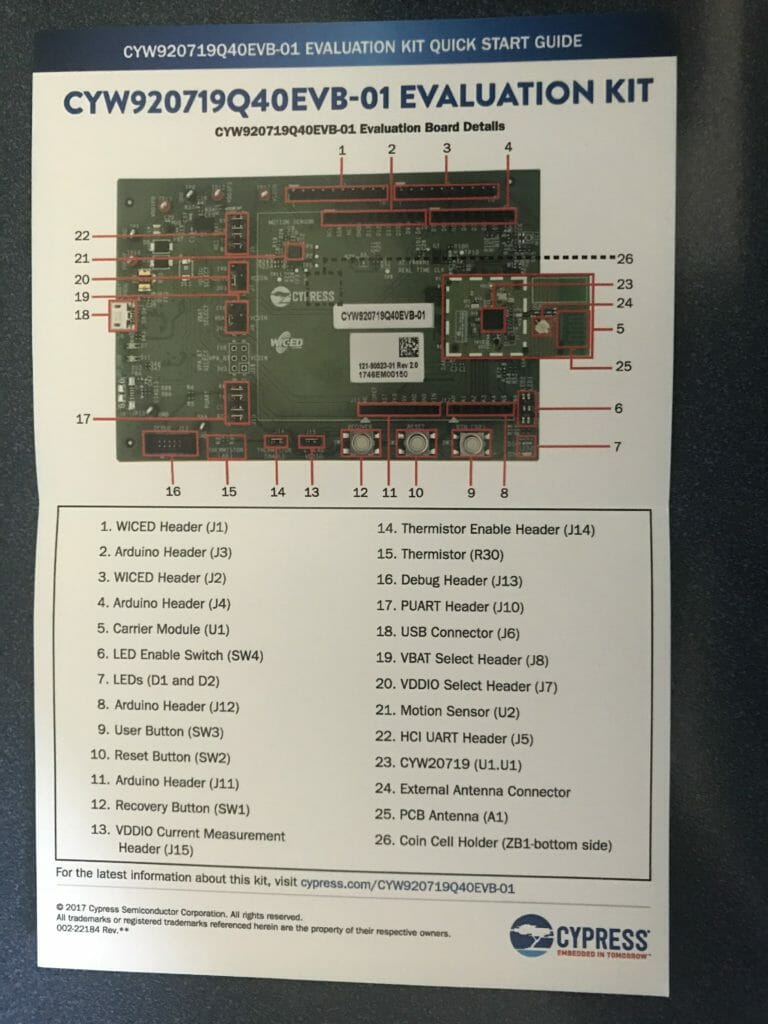

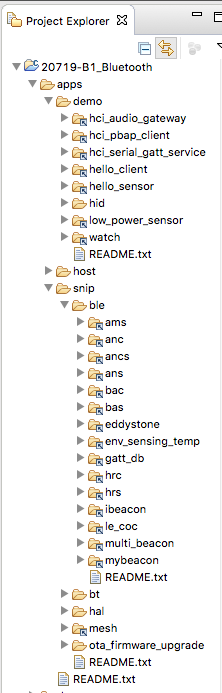

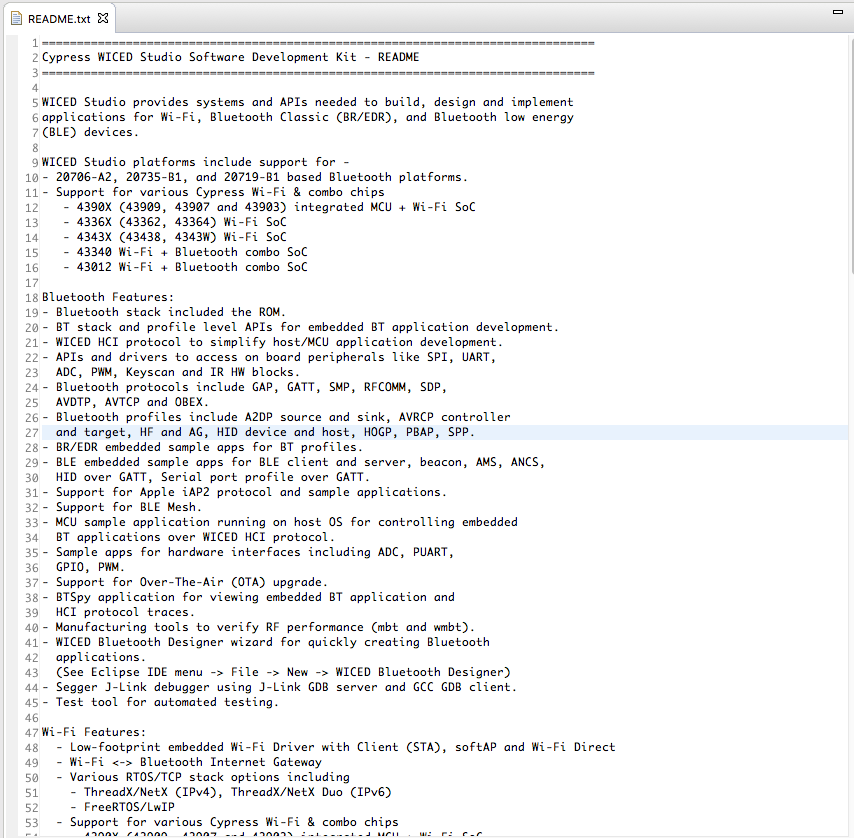

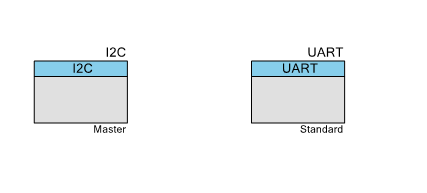

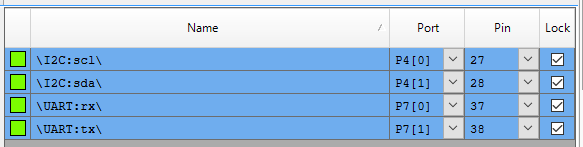

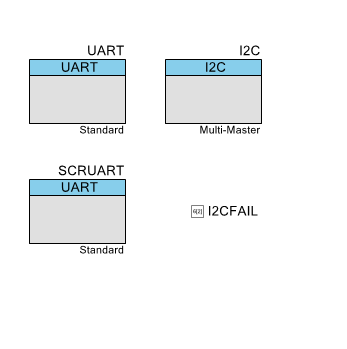

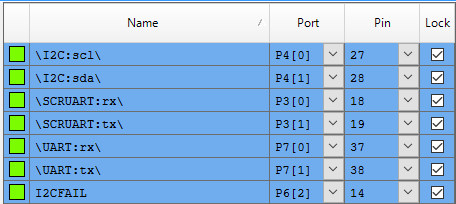

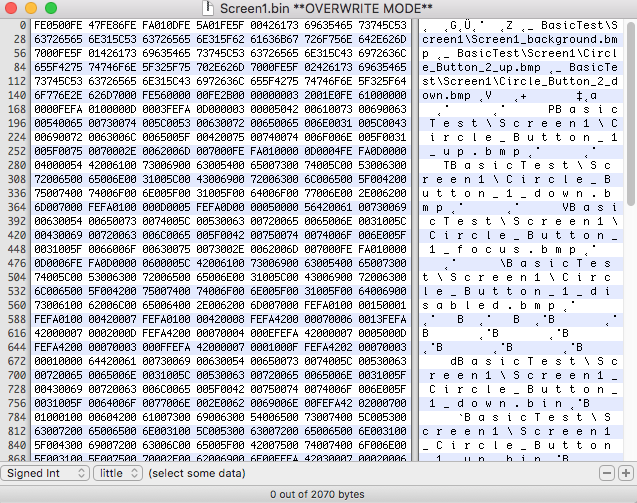

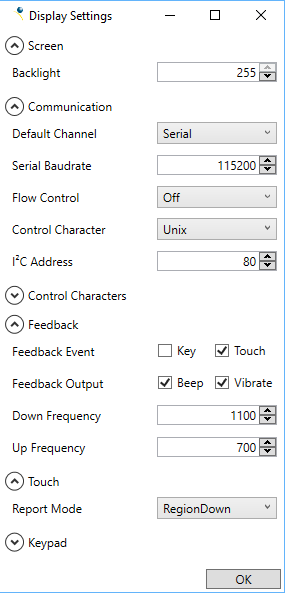

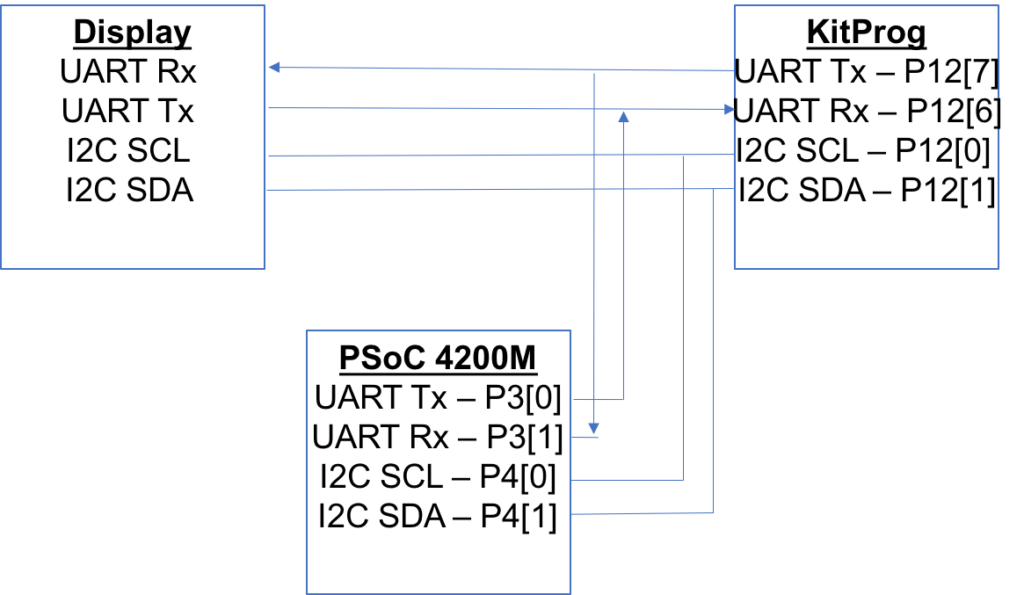

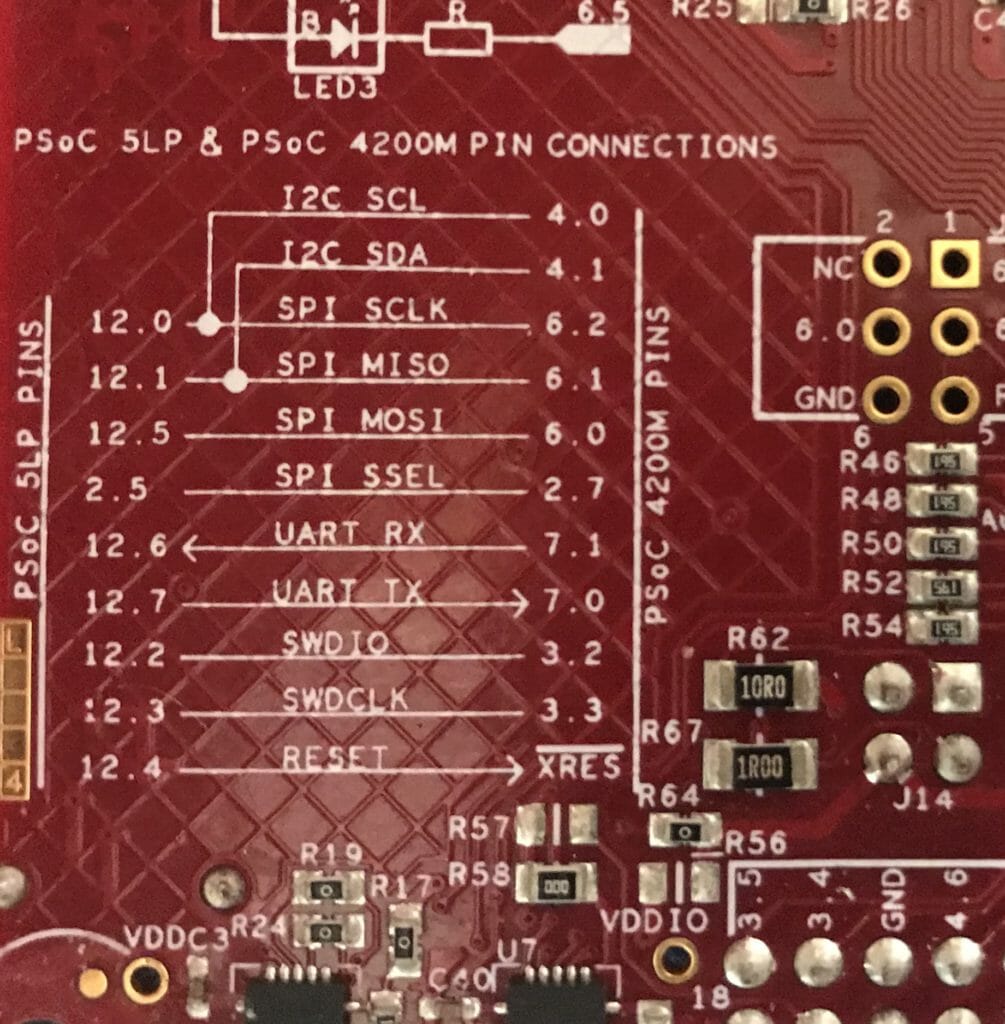

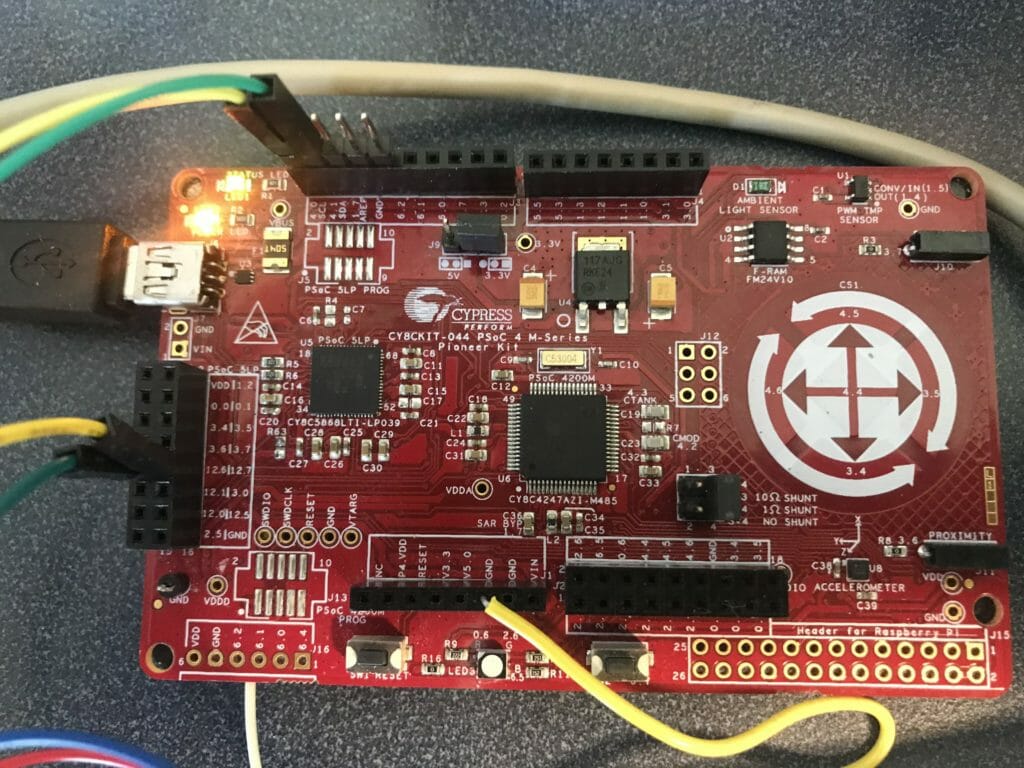

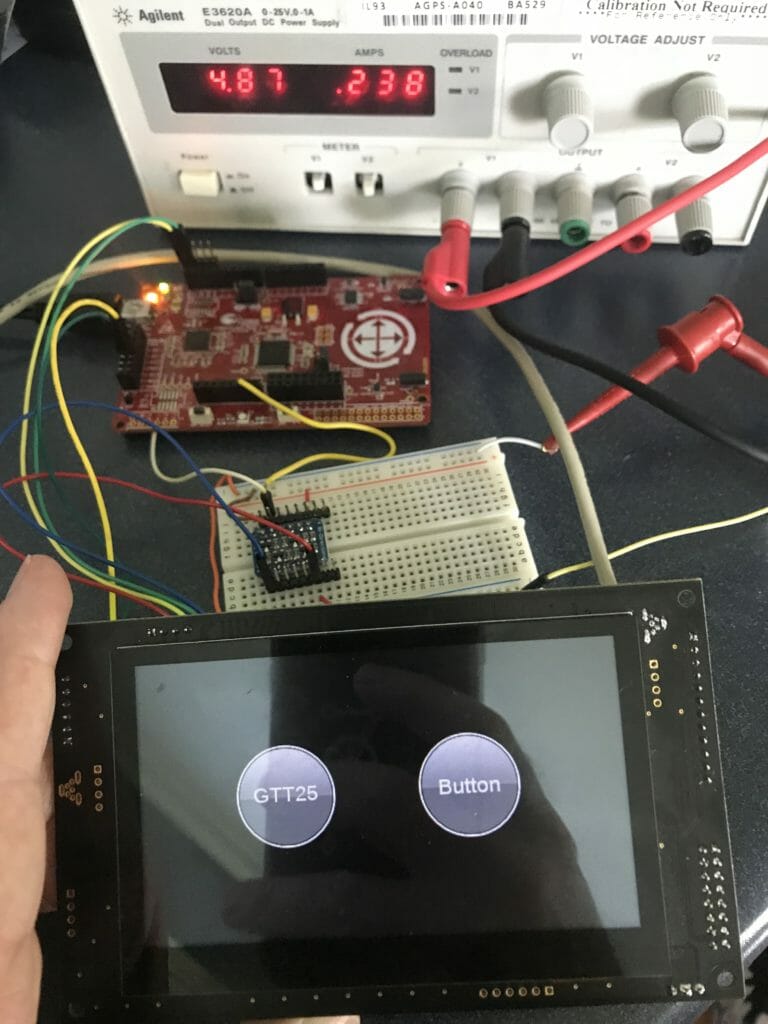

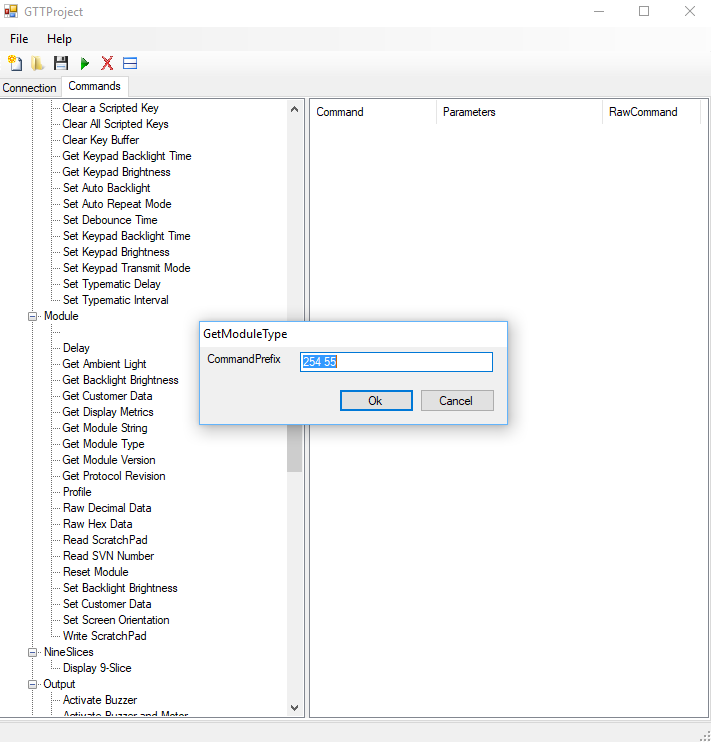

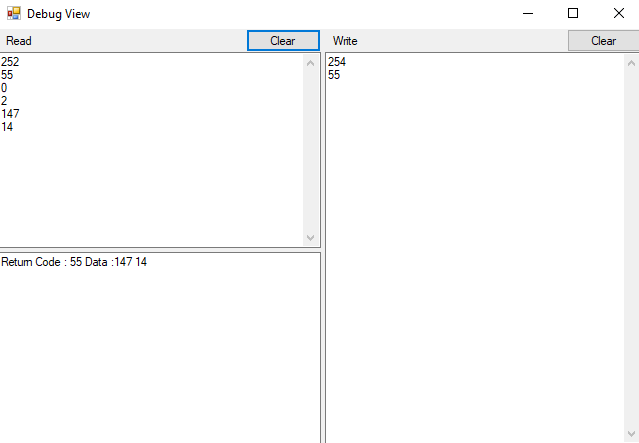

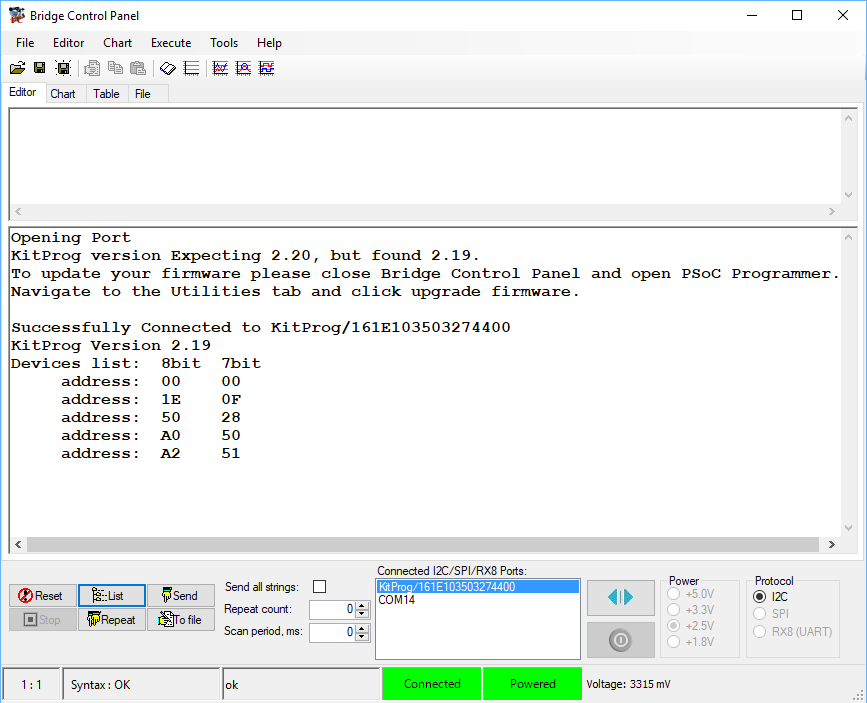

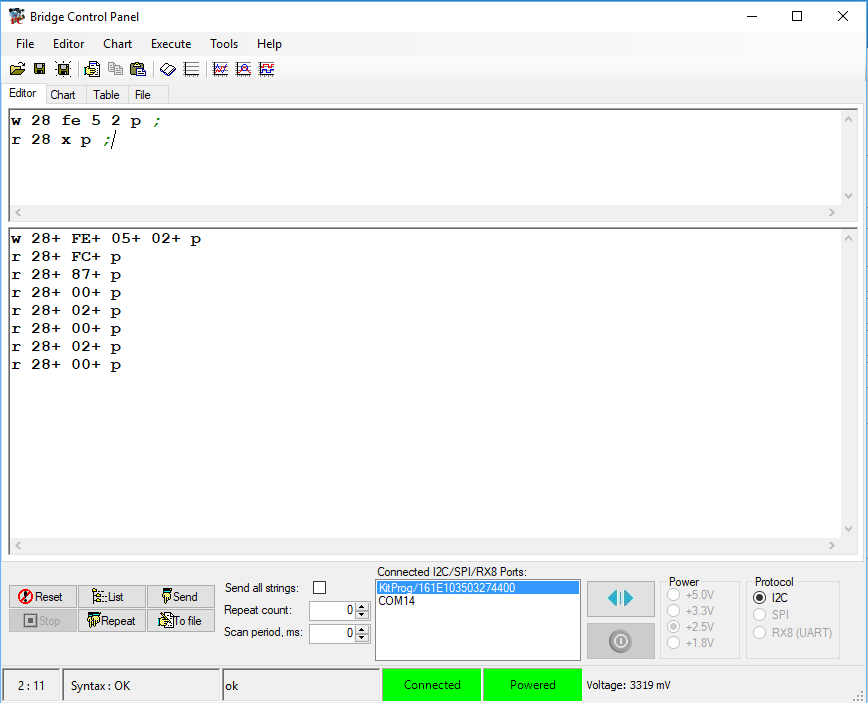

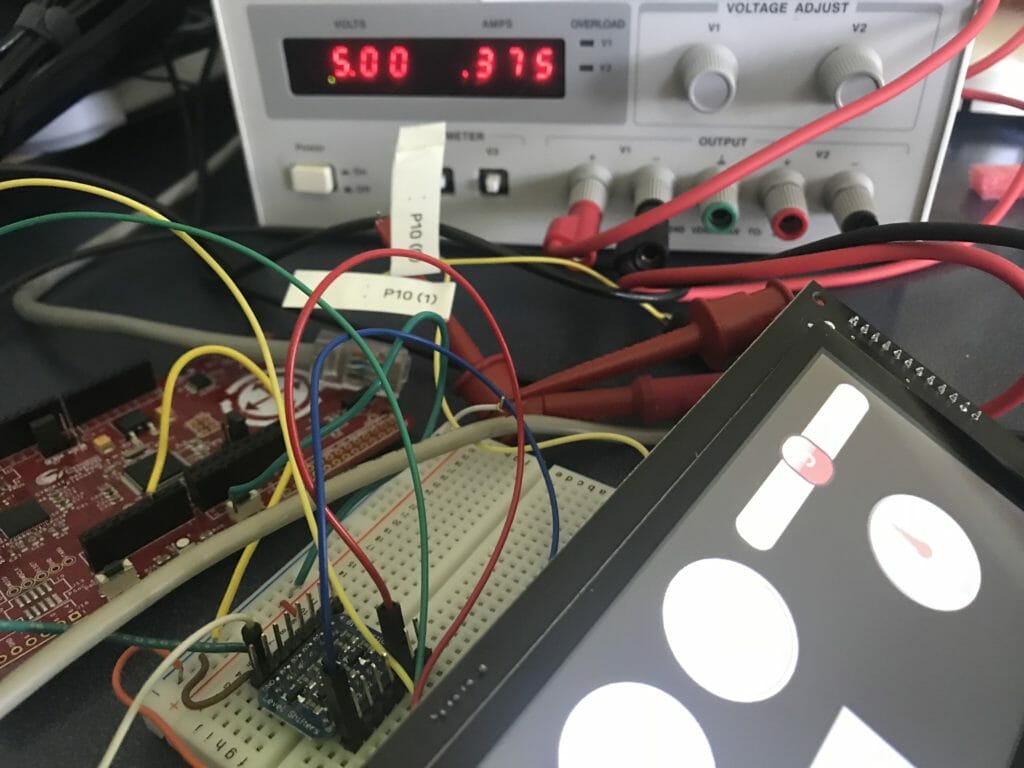

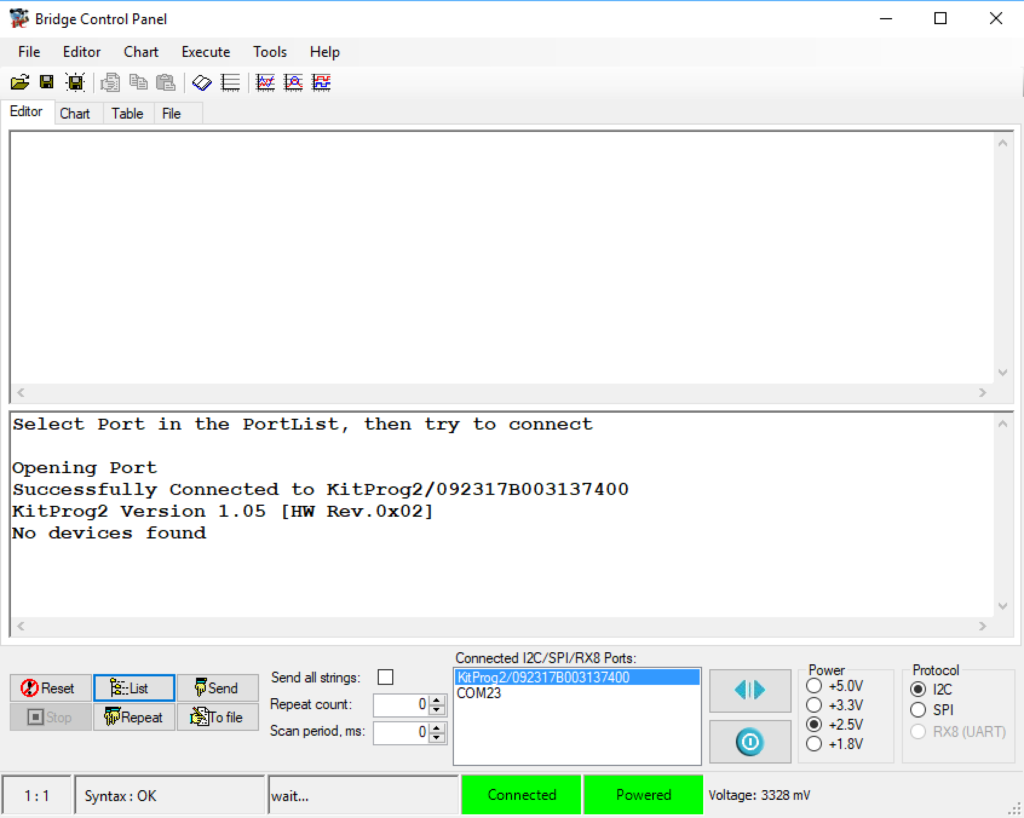

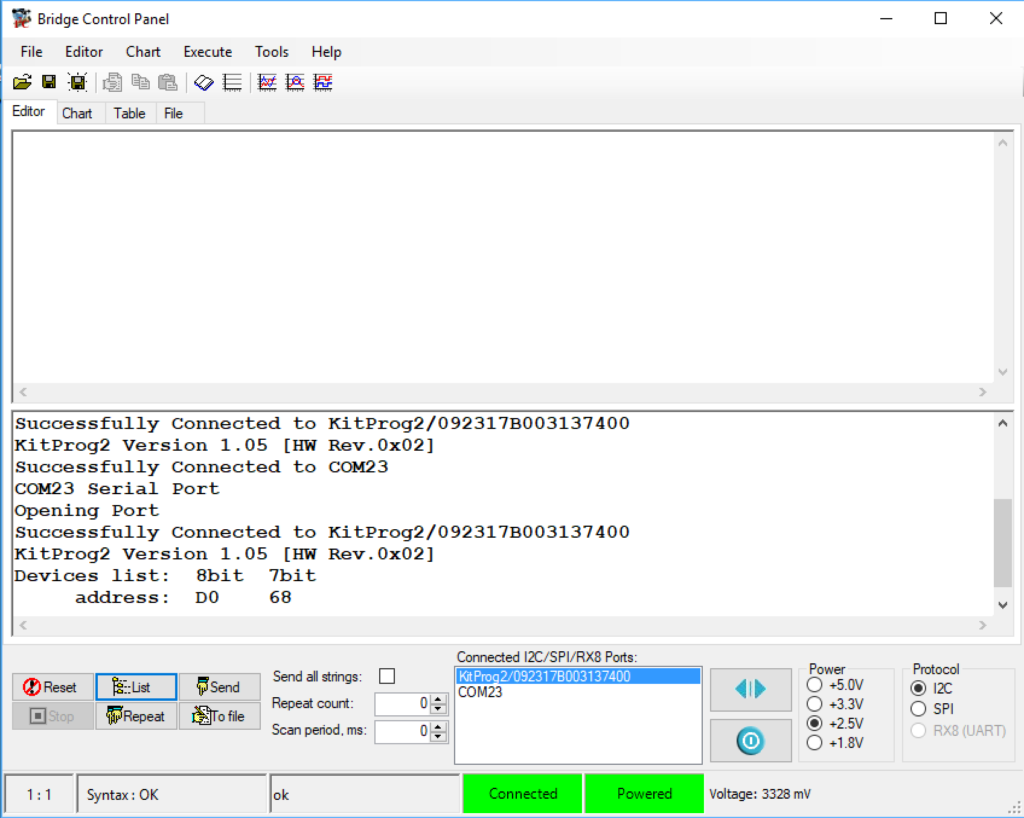

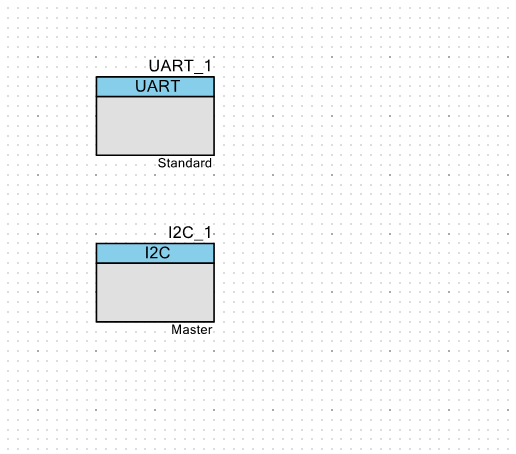

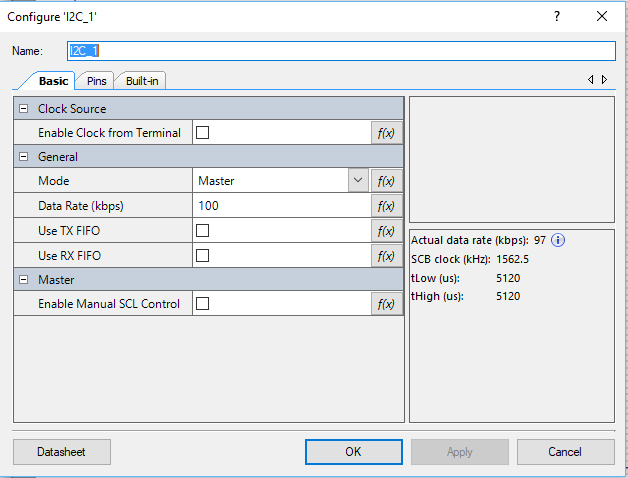

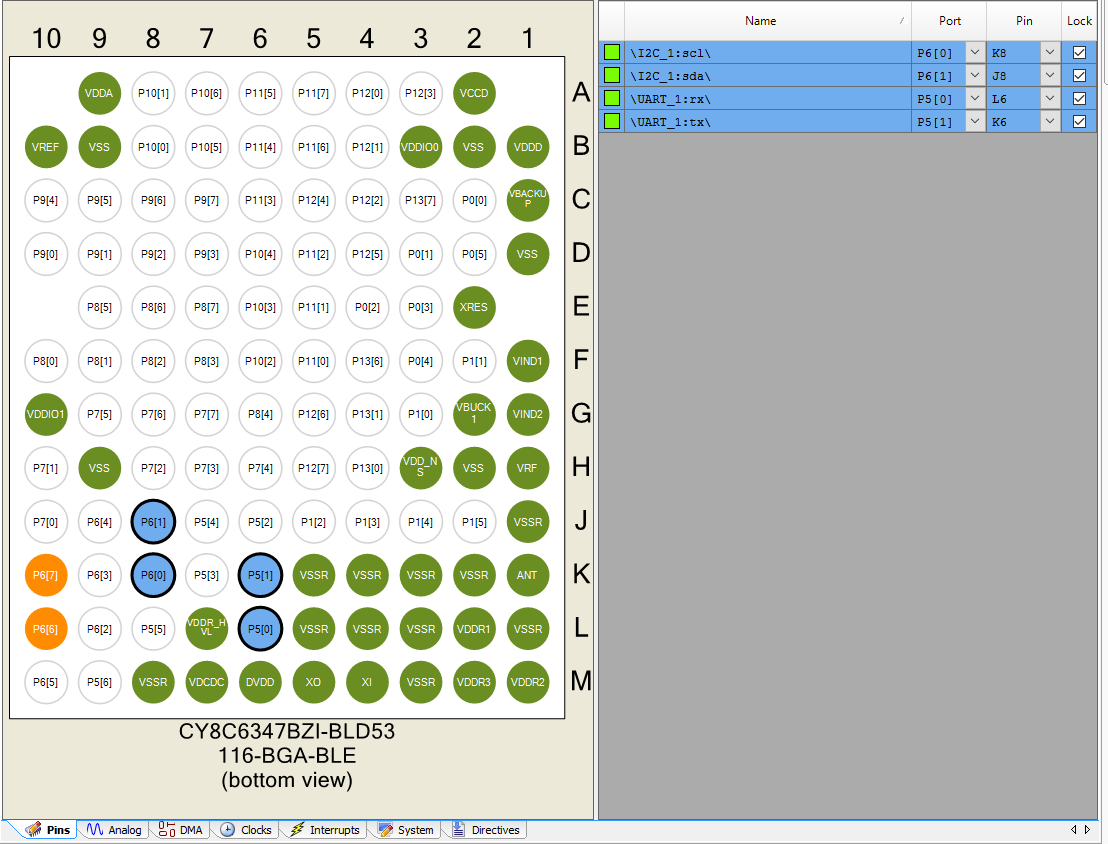

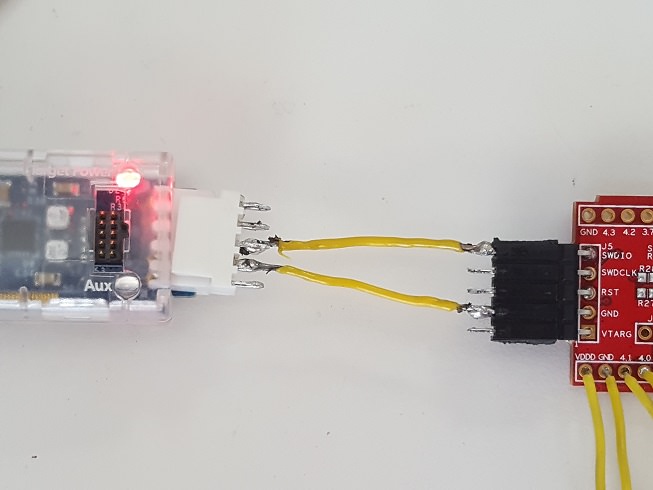

Run hal_i2c_master

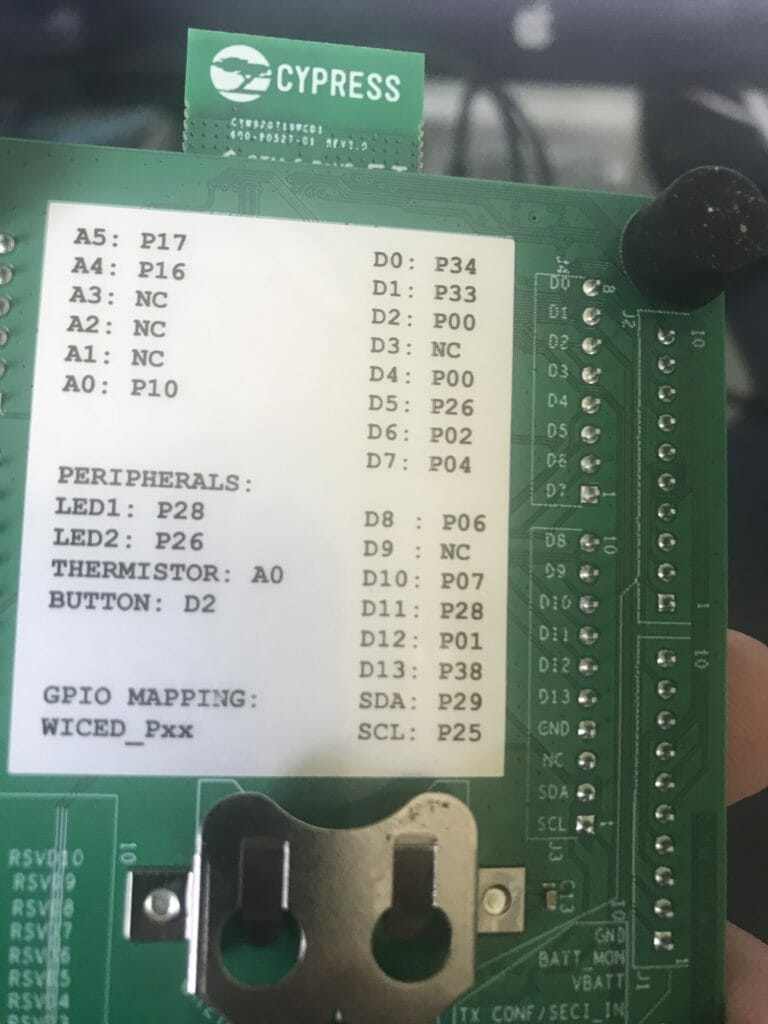

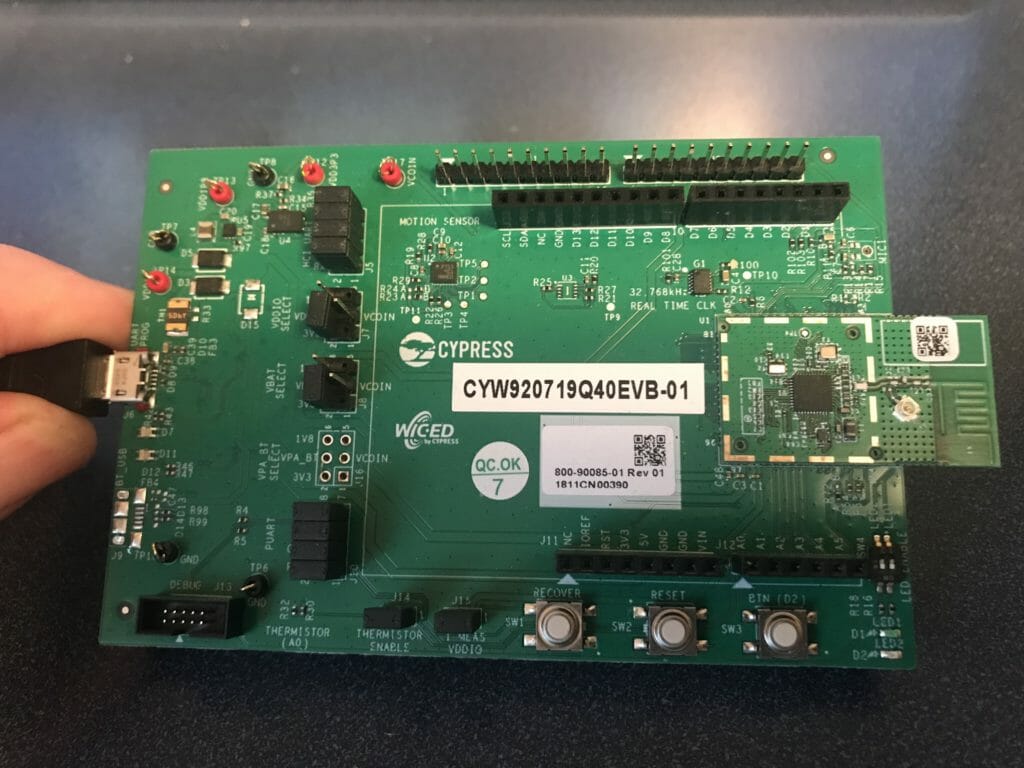

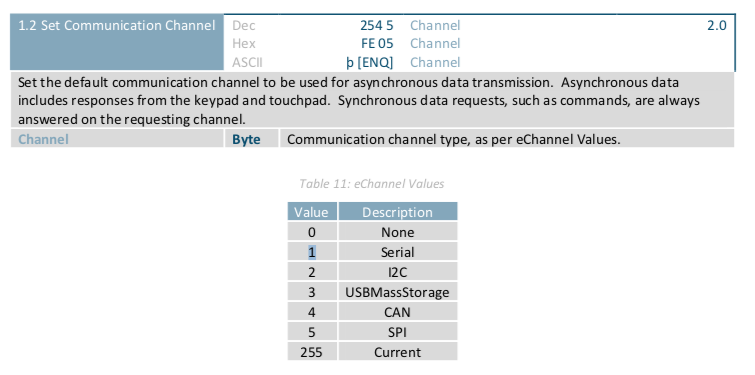

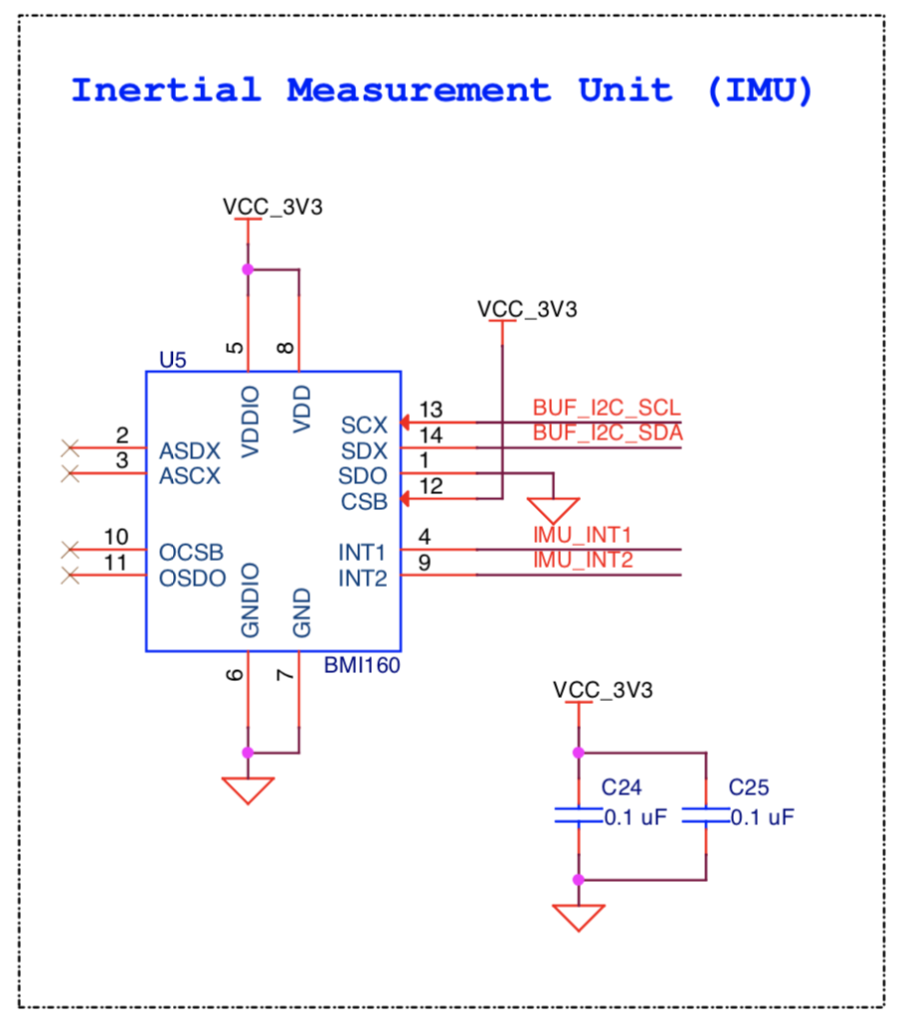

This CYW920719Q40EVB_01 development kit has an I2C LSM9DS1 accelerometer on it. And I noticed that when looking around in the snips that the Snip called “hal_i2c_master.c” appears to talk to the chip. Here is a little section of the comments from the top of the snip

* * WICED sample application for I2C Master usage * * This application demonstrates how to use I2C driver interface * to send and receive bytes or a stream of bytes over the I2C hardware as a master. * The on-board LSM9DS1 motion sensor acts as the I2C slave

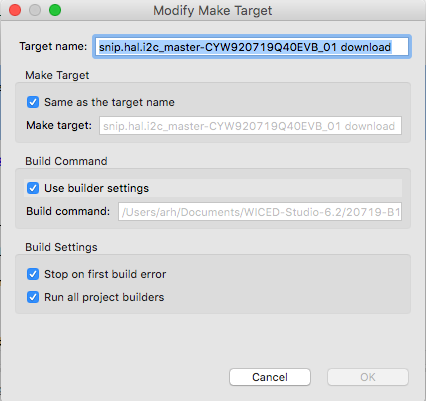

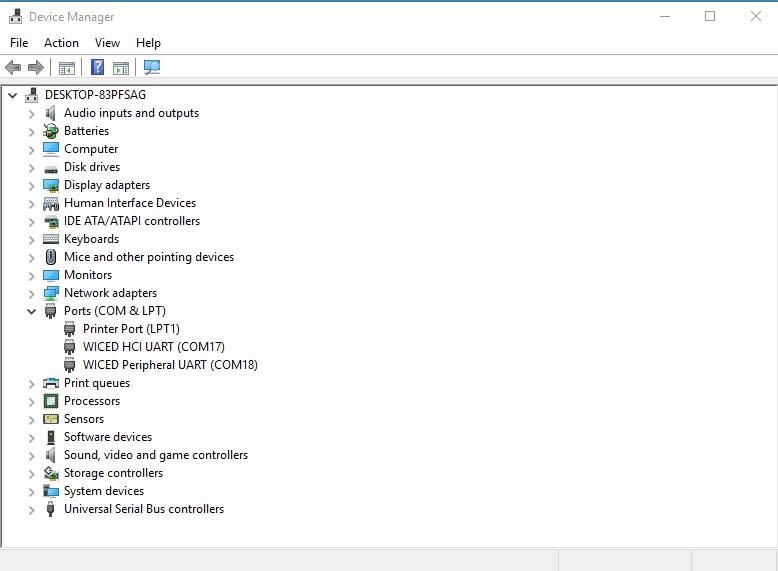

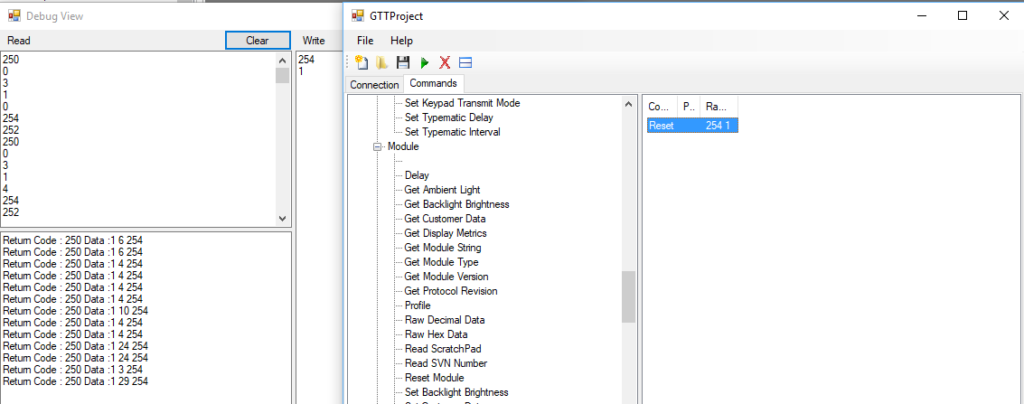

So, lets run the snip and see what happens. If you don’t have a make target… well then make one.

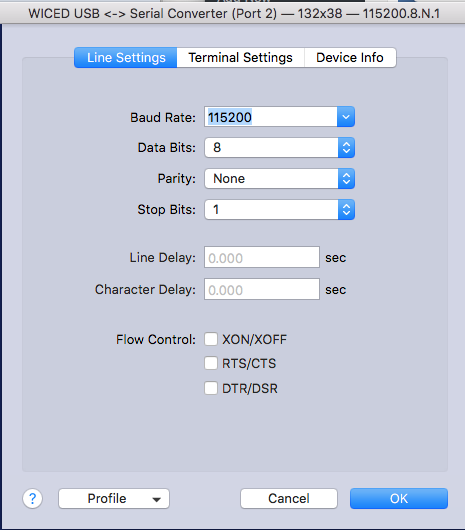

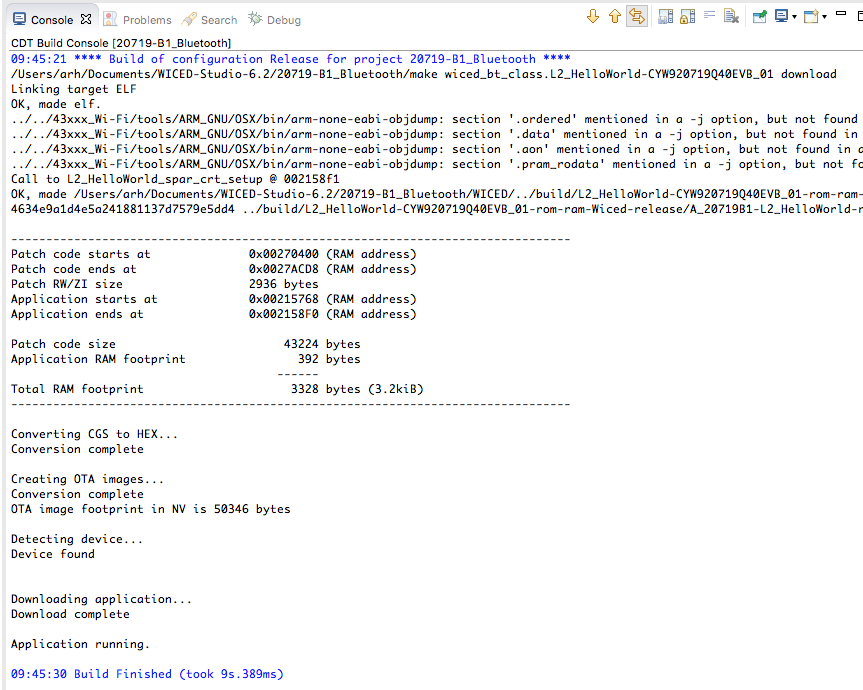

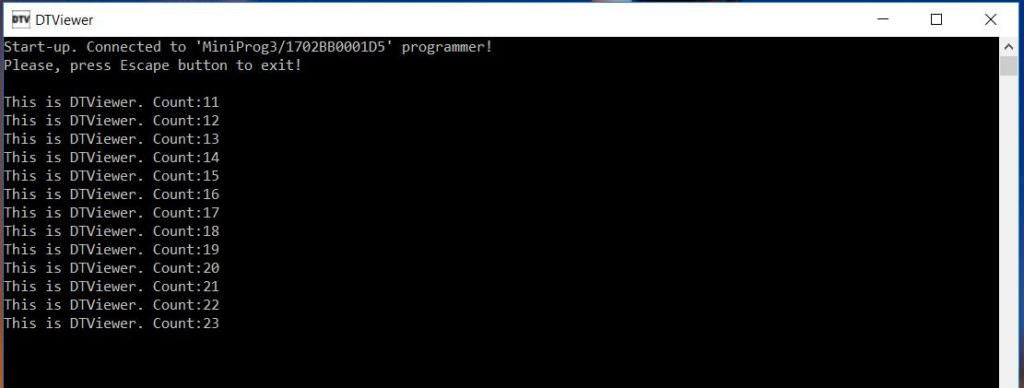

Then make the make target.

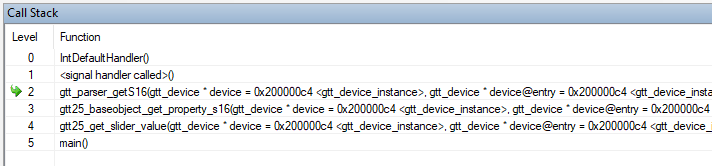

It turns out that “0” is a bug in the example project. And printing out the WHO_AM_I register isnt really very interesting.

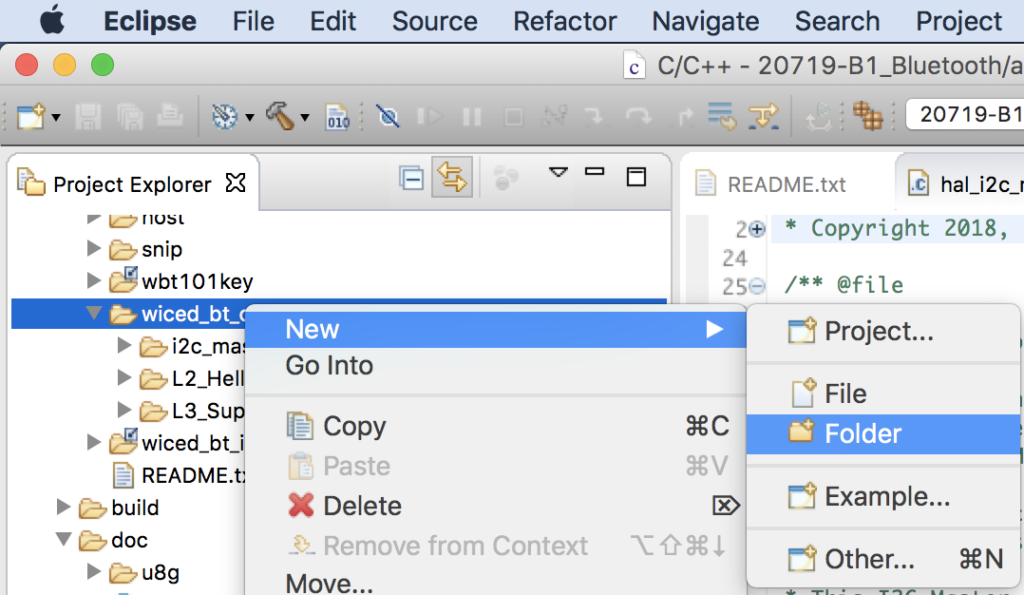

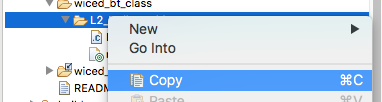

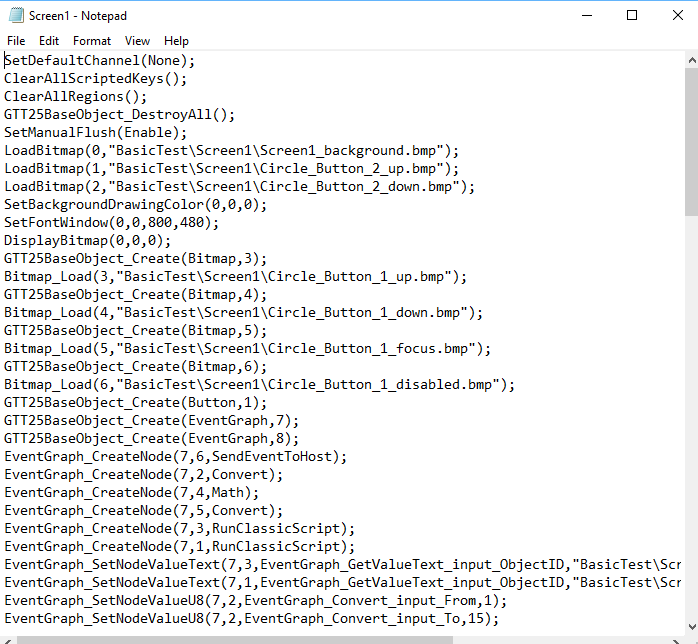

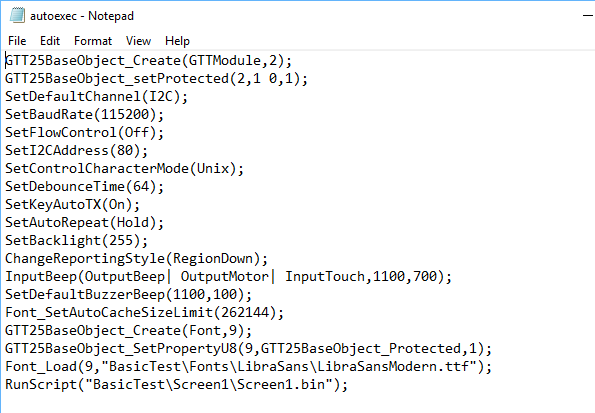

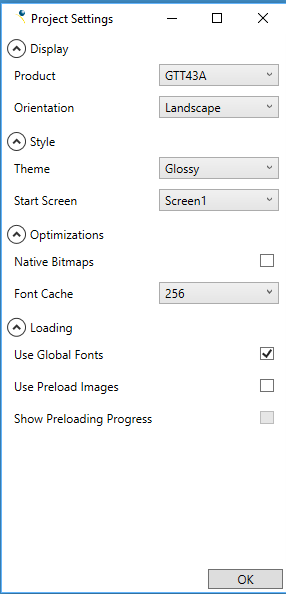

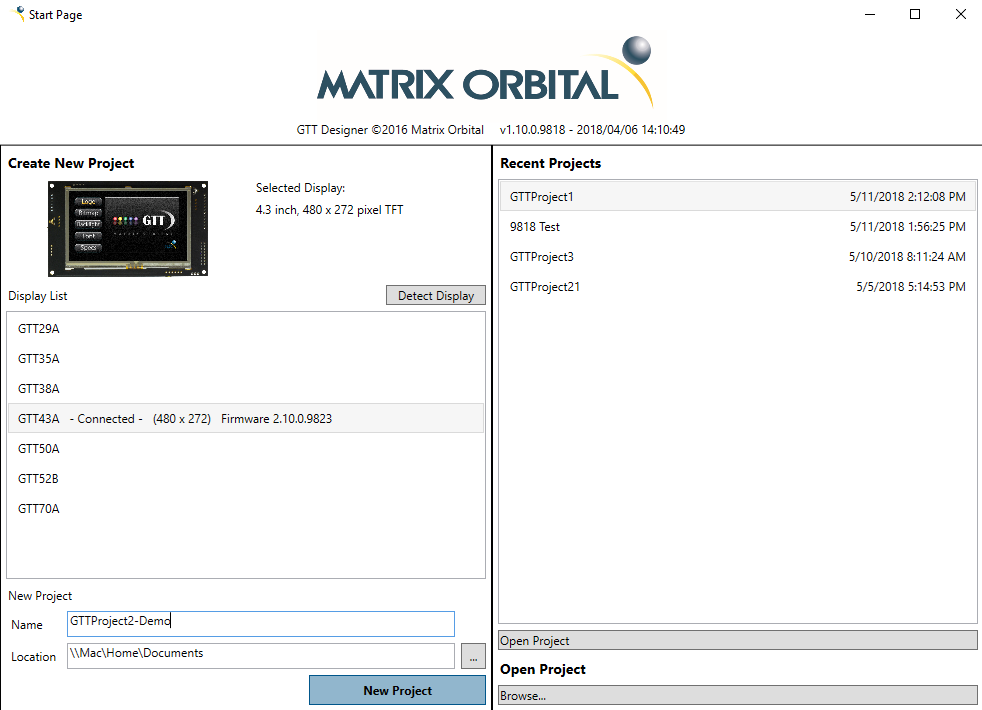

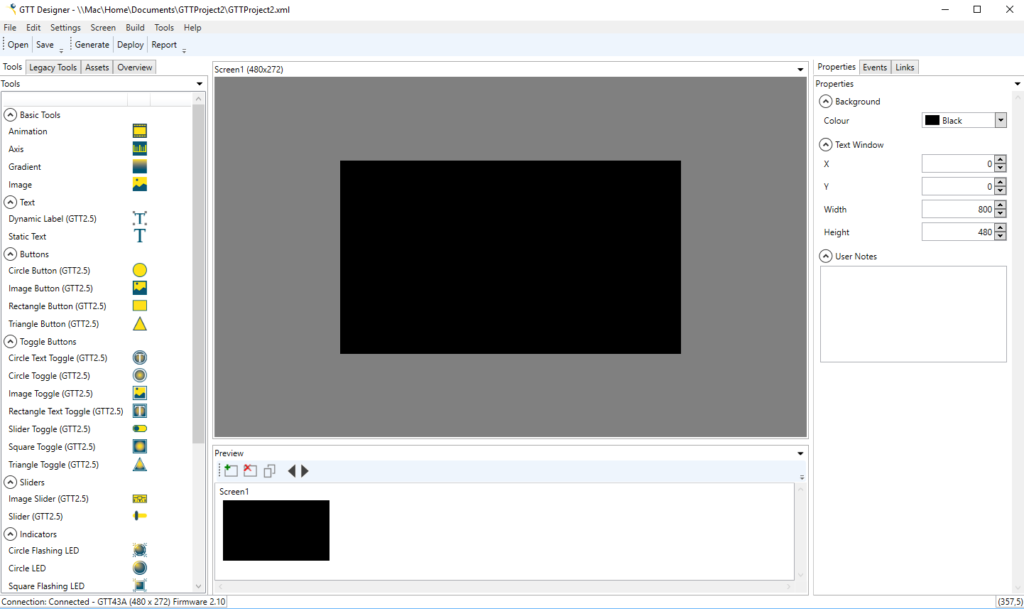

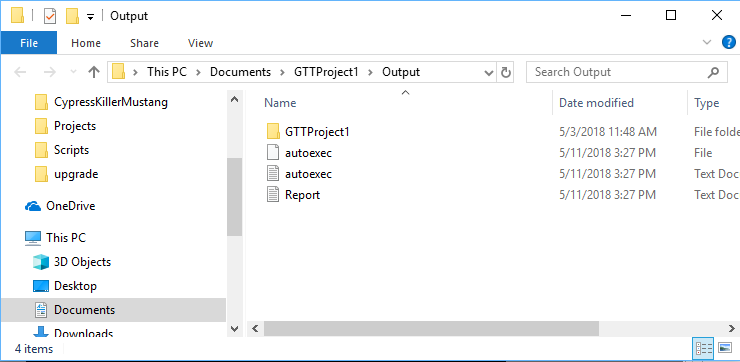

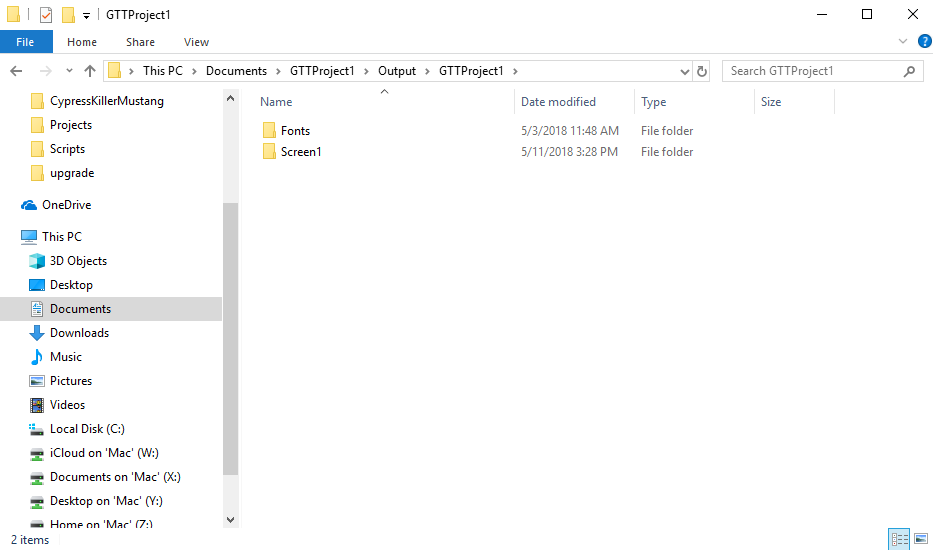

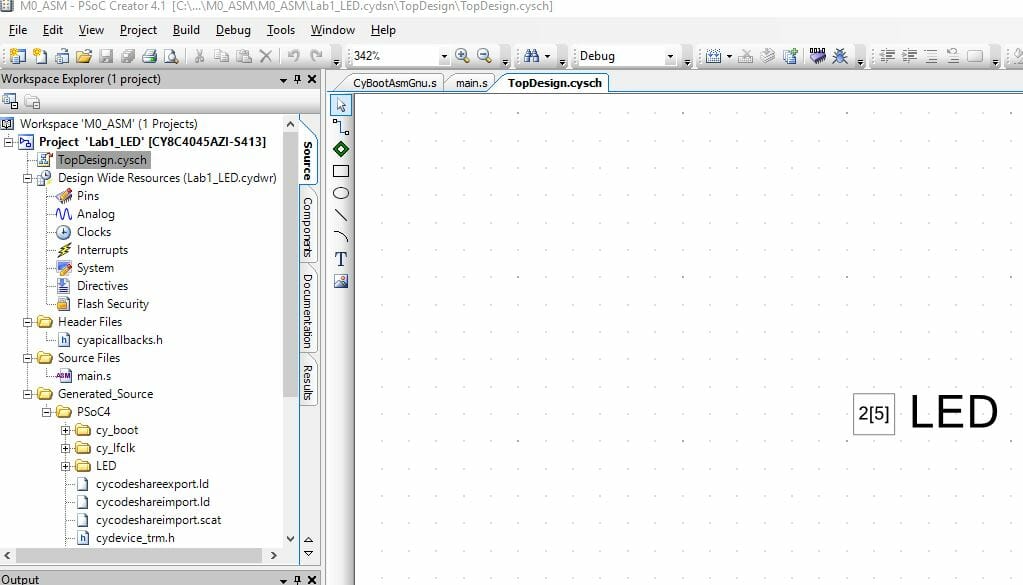

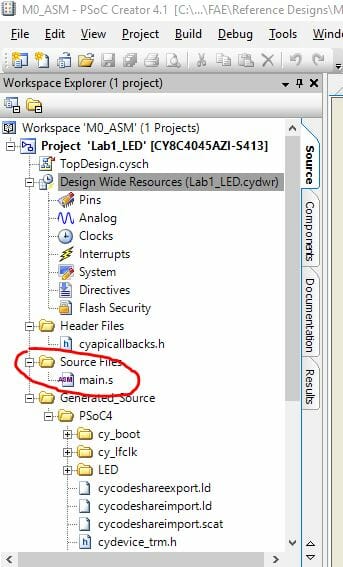

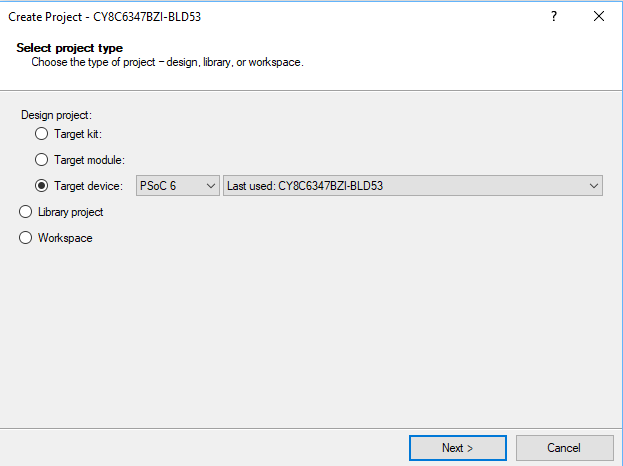

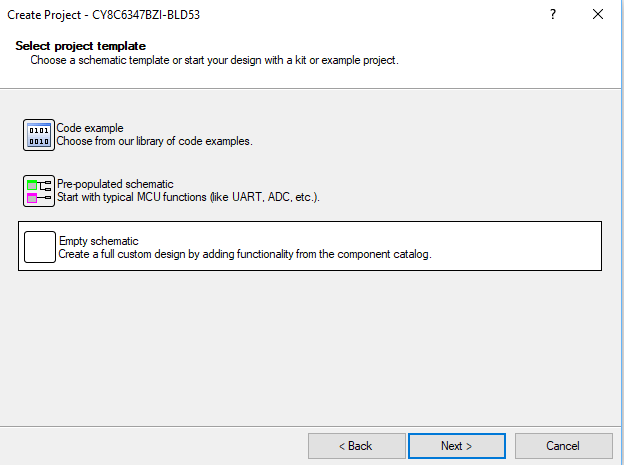

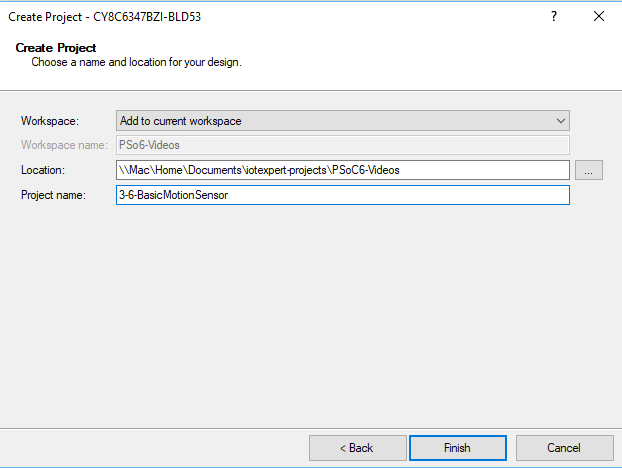

Modify the hal_i2c_master.c Create a Better Project

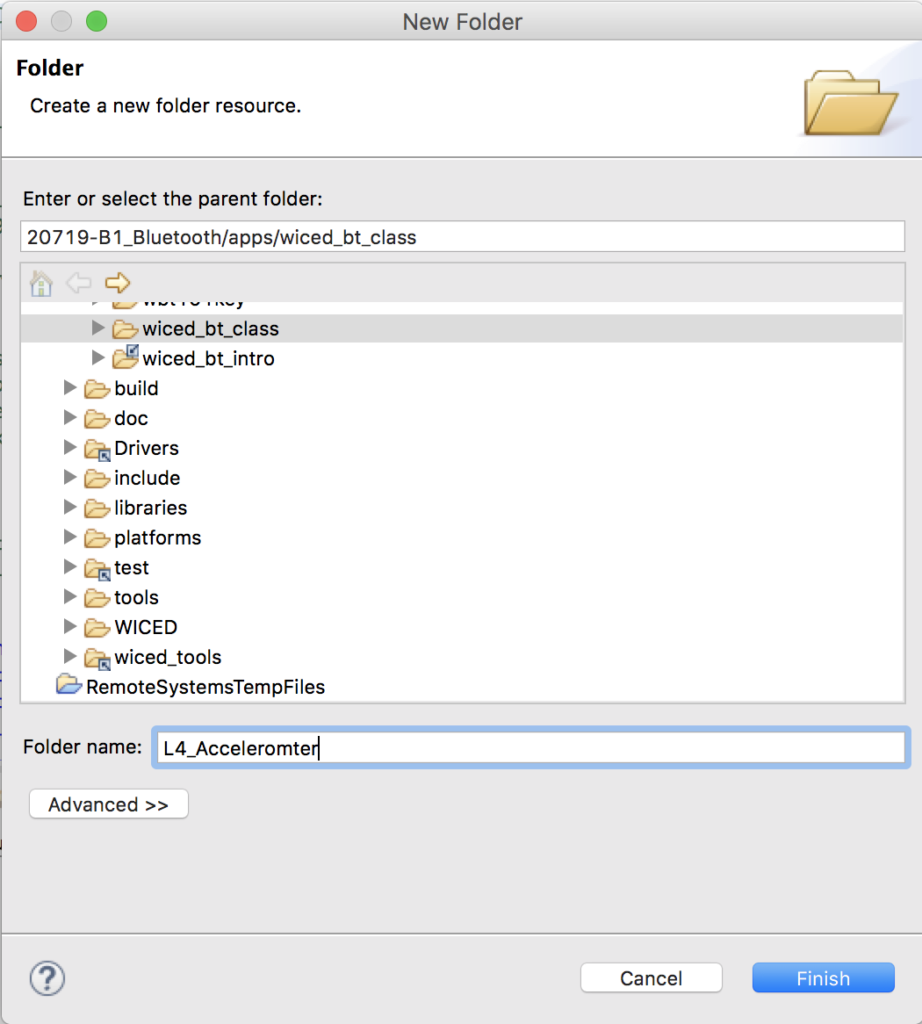

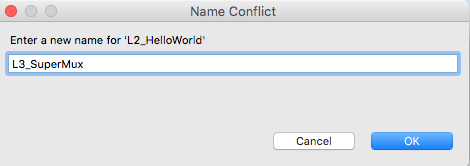

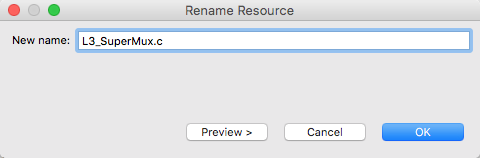

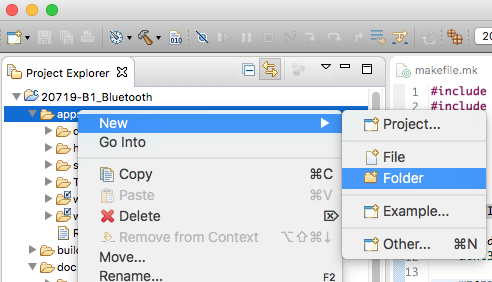

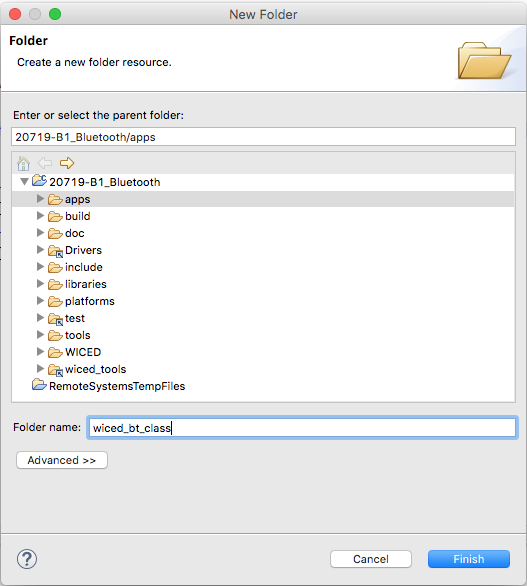

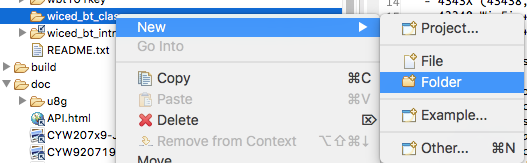

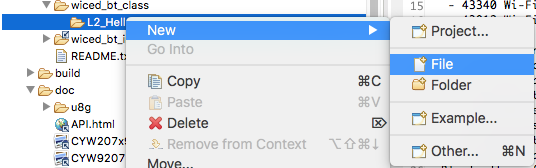

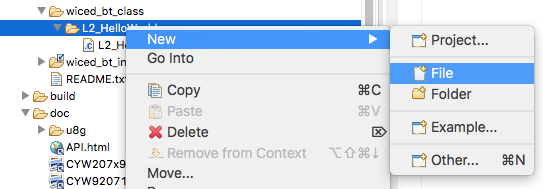

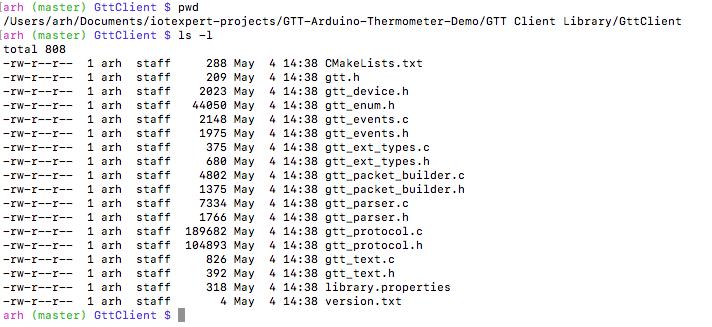

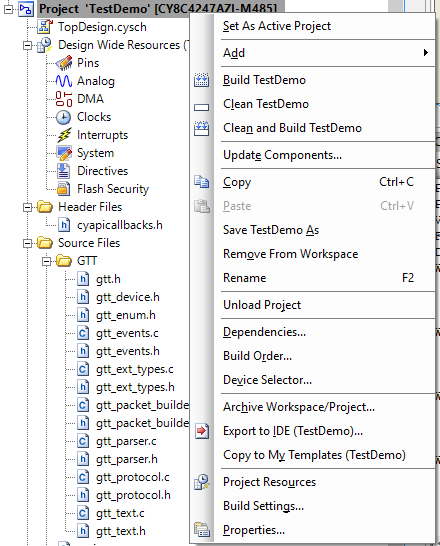

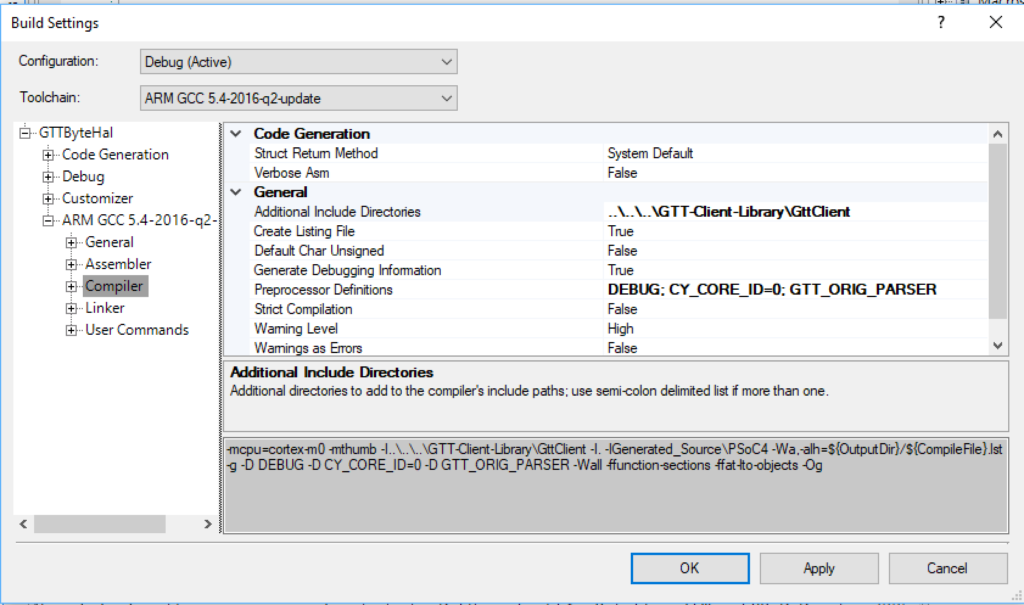

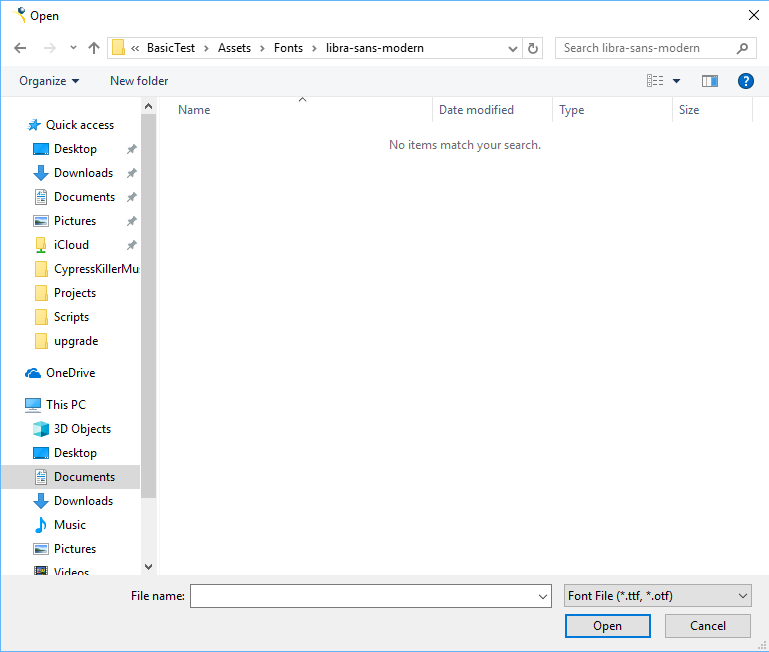

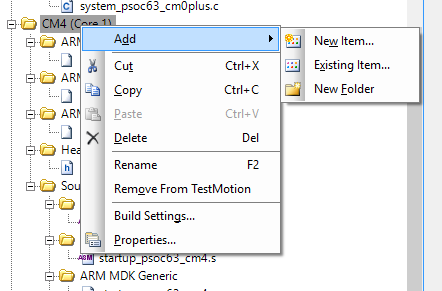

I don’t like making changes inside of the WICED SDK files. But, I want to fix the bug and printout something more interesting. So start by creating a new folder in the wiced_bt_class folder

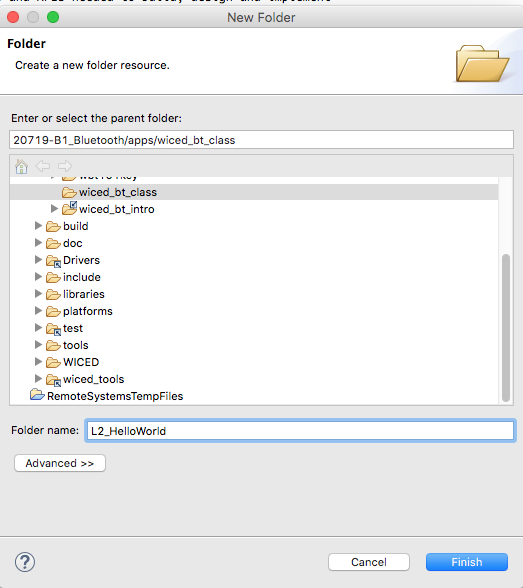

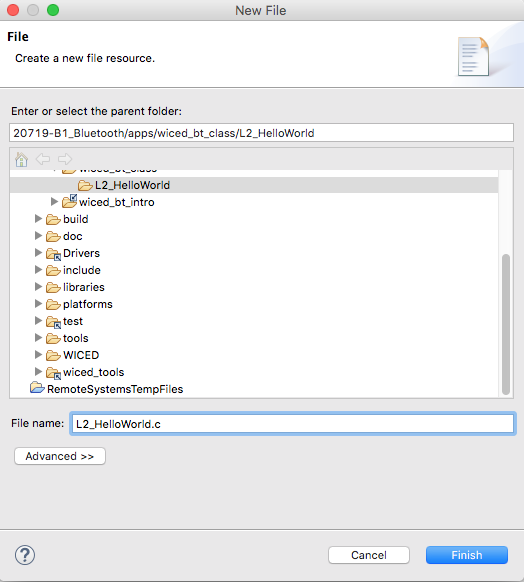

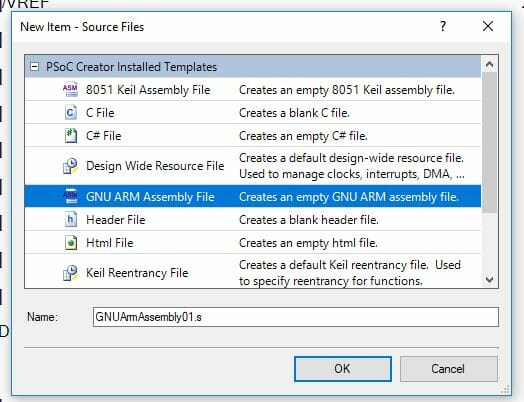

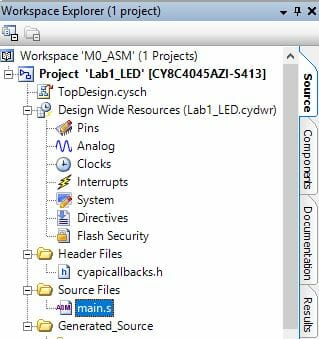

Type in the directory name L4_Accelerometer (notice in the screenshot below I mistyped it)

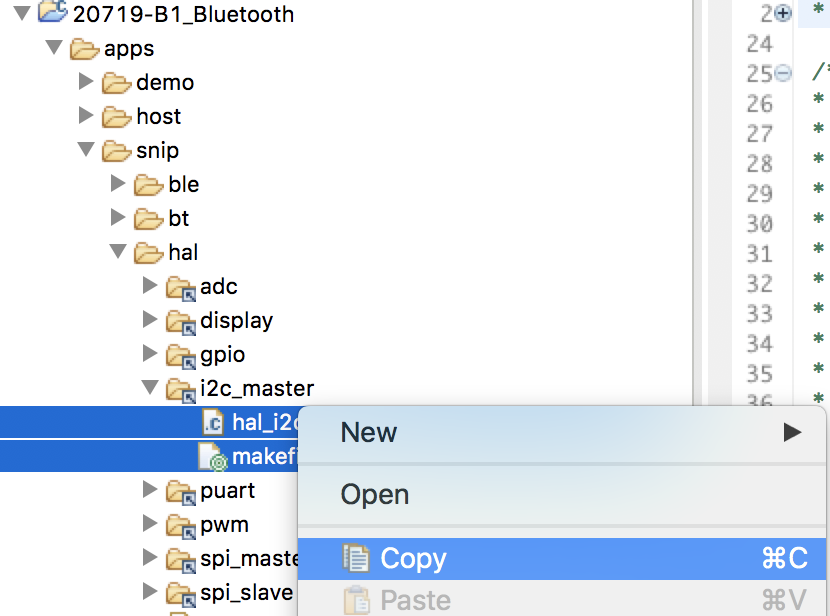

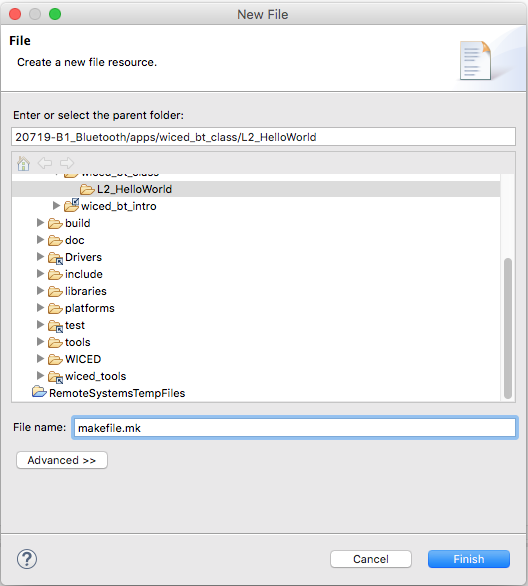

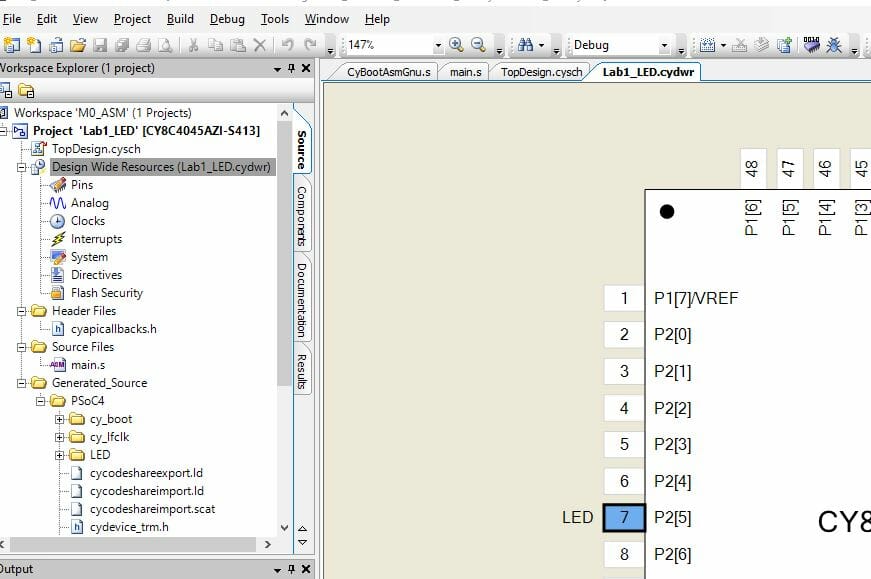

Select the makefile.mk and the hal_i2c_master.c then right click copy the files.

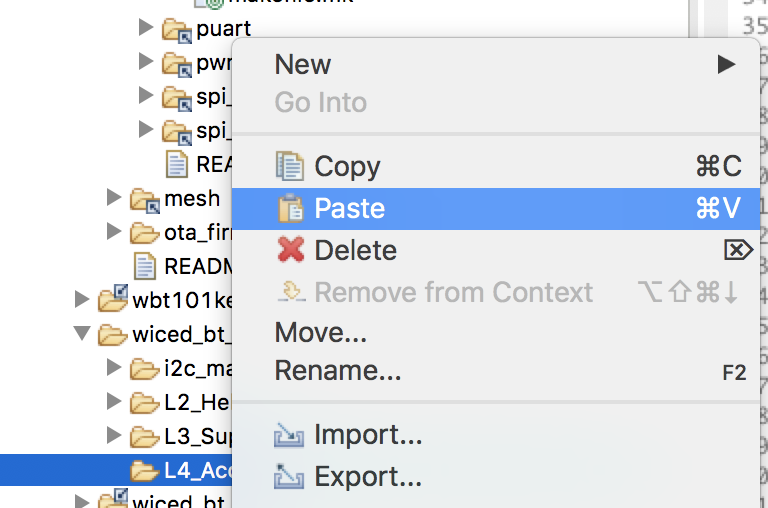

Then select the L4_Accelerometer folder and pick paste.

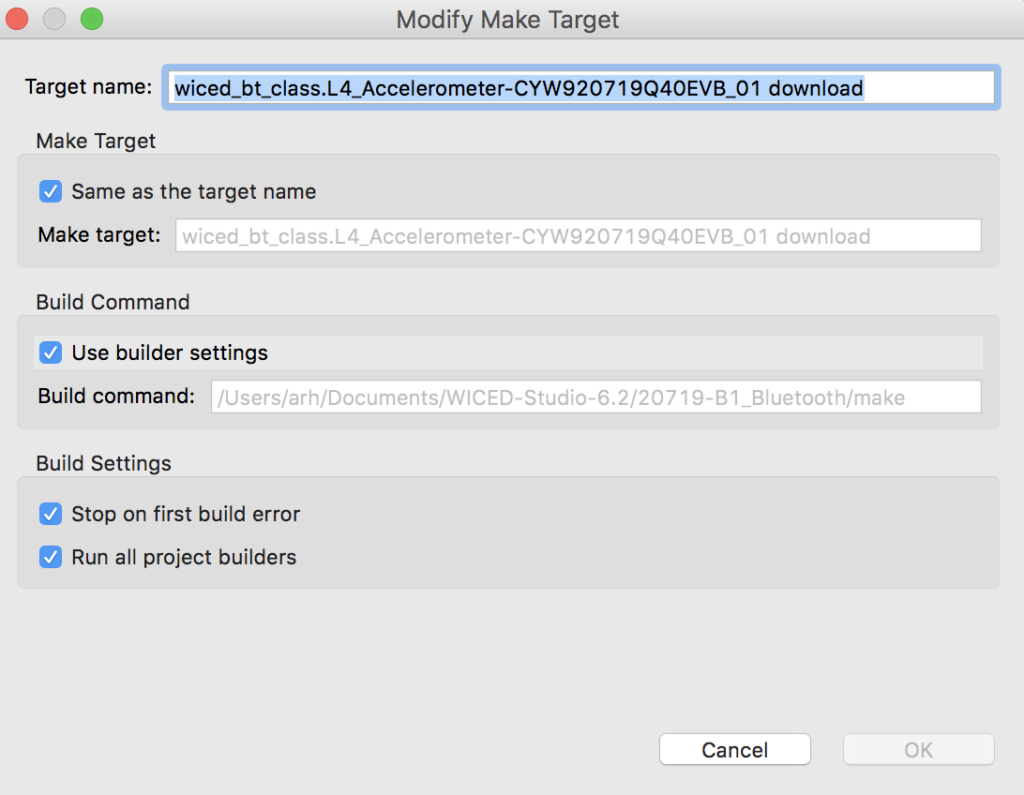

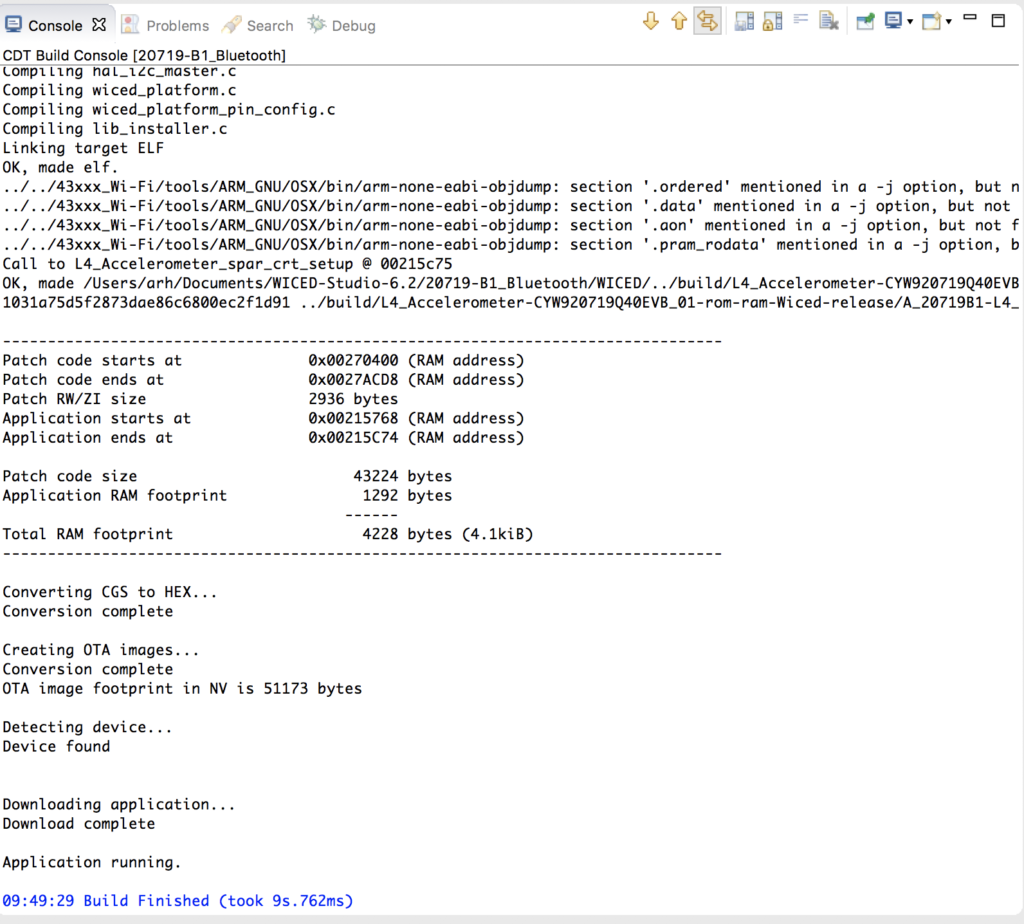

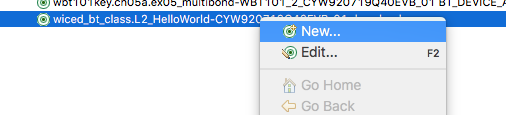

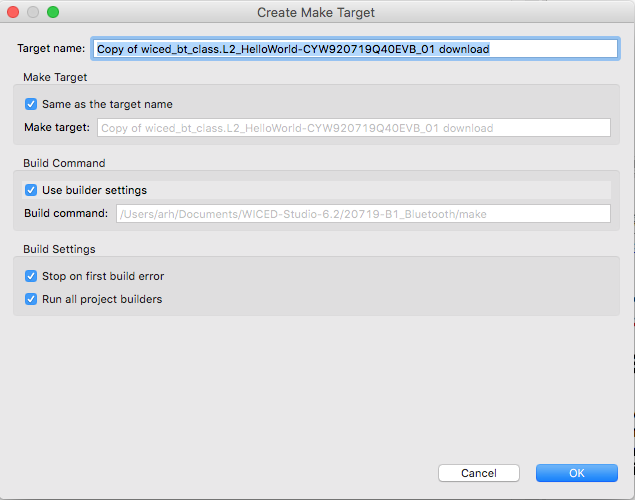

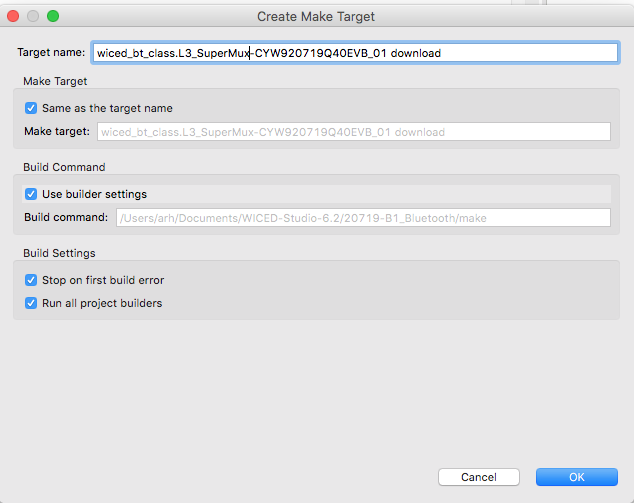

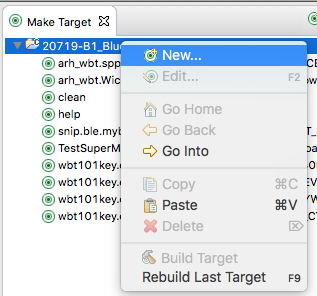

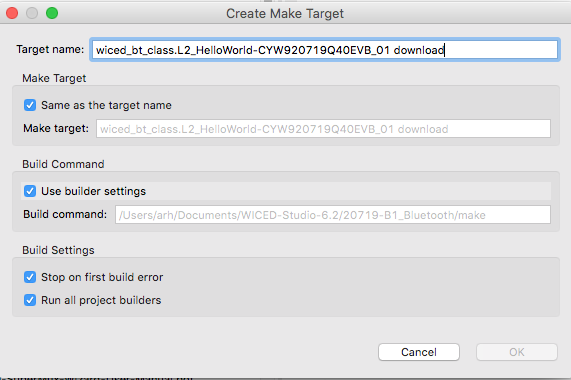

Create a make target for the L4_Accelerometer

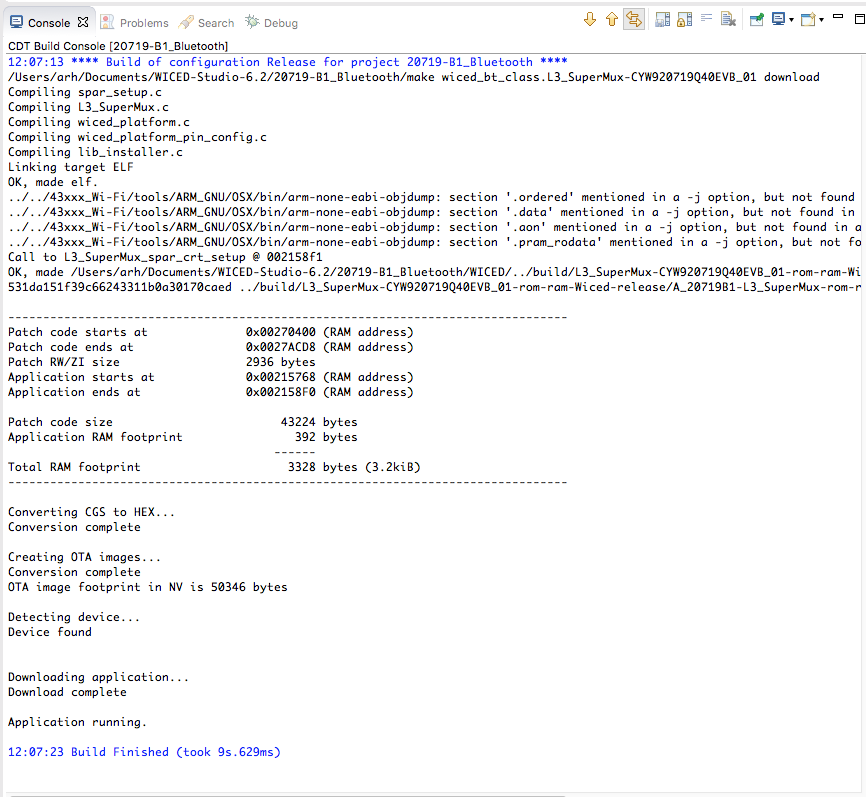

Build it to make sure it still works.

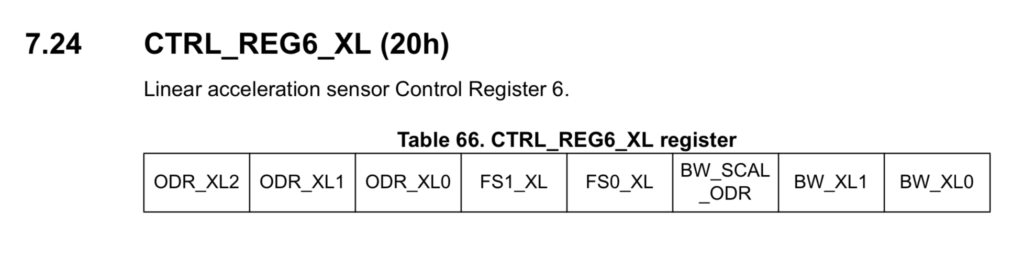

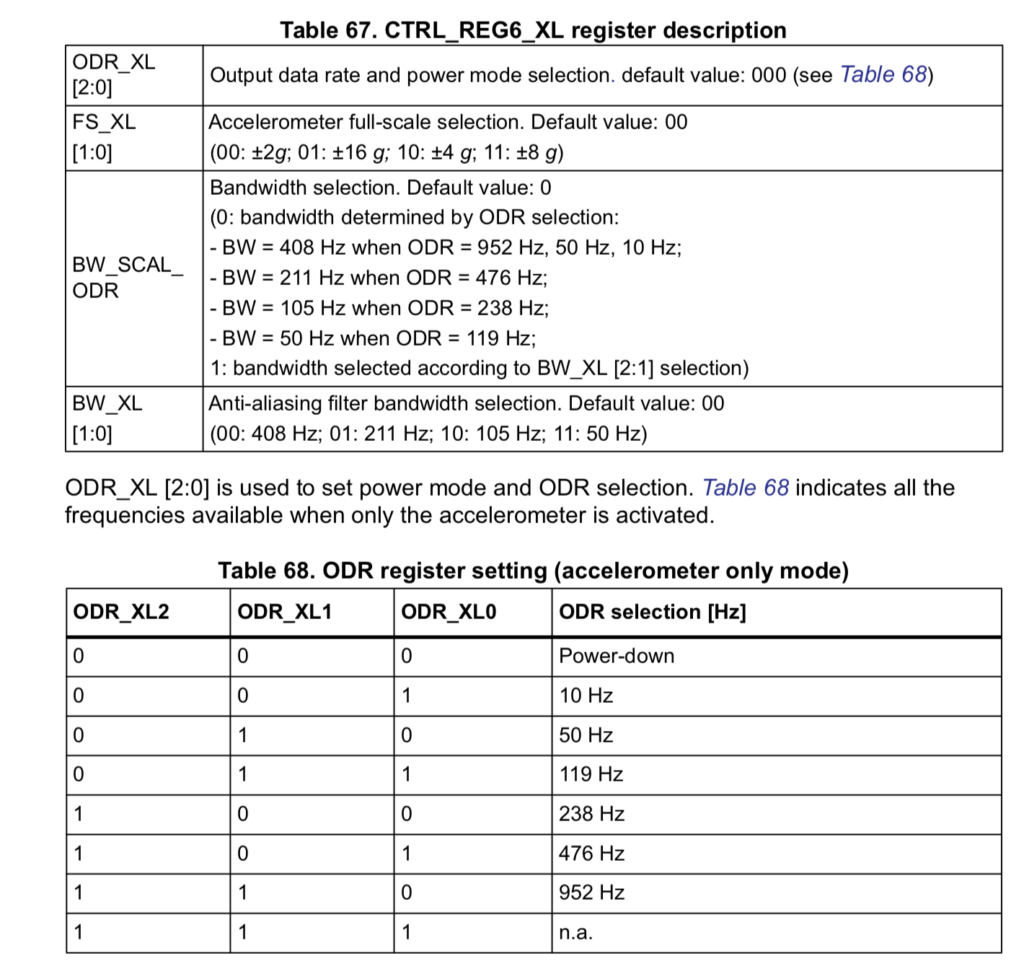

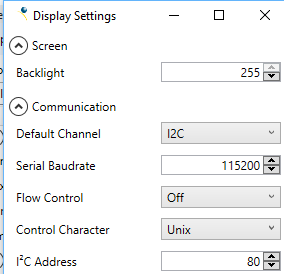

Now that we have a base to stand-on. Let’s have a look at the data sheet. I have used these before and I know that you need to turn on the Accelerometer to give you anything interesting. Turns out CTRL_REG_6_XL is the control register we need.

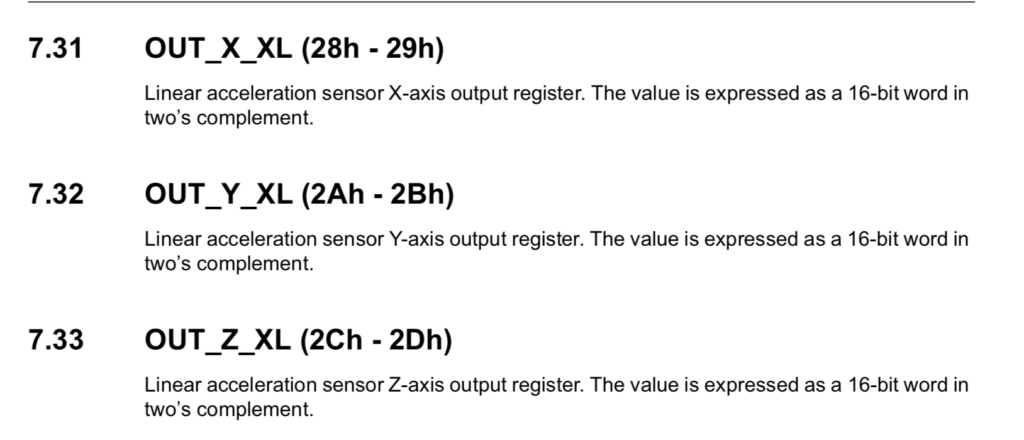

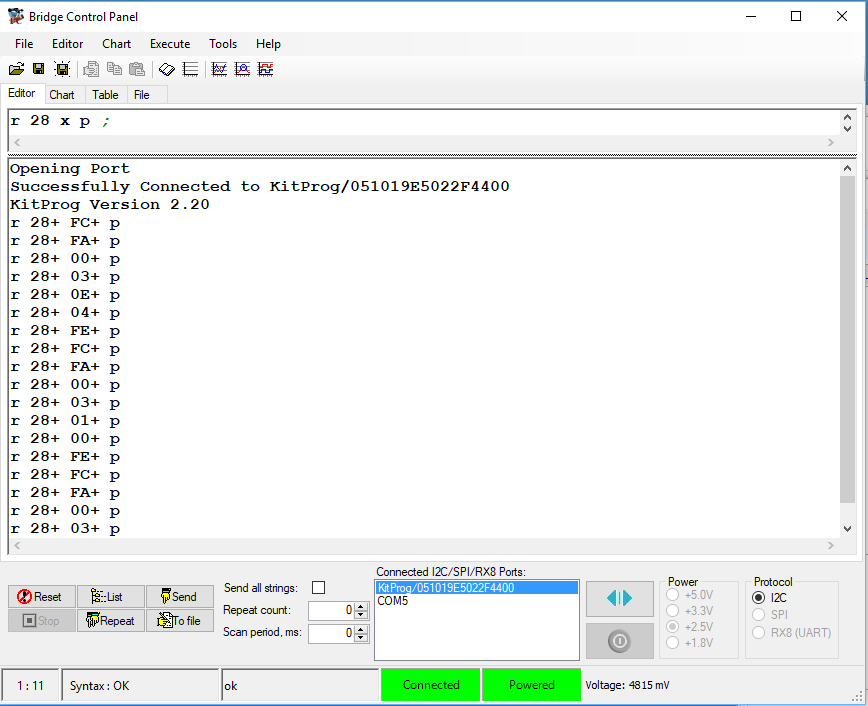

The other interesting registers are the actual output of the accelerometer. That is 0x28 –> 0x2D

Start by modifying the function initialize_app to turn on the accelerometer by writing 0x40 to register 0x20

uint8_t status;

// Turn on Accelerometer - Register 0x20... 2g accelerometer on @ 50hz

uint8_t data[] = {0x20, 0x40};

status = wiced_hal_i2c_write(data,sizeof(data),LSM9DS1_ACC_GYRO_I2C_ADDRESS);

I dont really like printing the values every two seconds so I will modify the timer:

- Make it a milisecond timer

- Set it to print every 500ms

if ( WICED_SUCCESS == wiced_init_timer( &seconds_timer, &comboread_cb, 0, WICED_MILLI_SECONDS_PERIODIC_TIMER )) {

if ( WICED_SUCCESS != wiced_start_timer( &seconds_timer, 500 )) {

WICED_BT_TRACE( "Seconds Timer Error\n\r" );

}

}

Here is the whole function initialize_app together

void initialize_app( void )

{

wiced_hal_i2c_init();

uint8_t status;

// Turn on Accelerometer - Register 0x20... 2g accelerometer on @ 50hz

uint8_t data[] = {0x20, 0x40};

status = wiced_hal_i2c_write(data,sizeof(data),LSM9DS1_ACC_GYRO_I2C_ADDRESS);

/* register callback for button available on the platform */

wiced_platform_register_button_callback( WICED_PLATFORM_BUTTON_1, button_cb, NULL, WICED_PLATFORM_BUTTON_RISING_EDGE);

current_speed = wiced_hal_i2c_get_speed();

WICED_BT_TRACE("Default I2C speed: %d KHz\n", (CLK_FREQ/current_speed));

/*Start a timer for POLL_TIMER seconds*/

if ( WICED_SUCCESS == wiced_init_timer( &seconds_timer, &comboread_cb, 0, WICED_MILLI_SECONDS_PERIODIC_TIMER )) {

if ( WICED_SUCCESS != wiced_start_timer( &seconds_timer, 500 )) {

WICED_BT_TRACE( "Seconds Timer Error\n\r" );

}

}

}

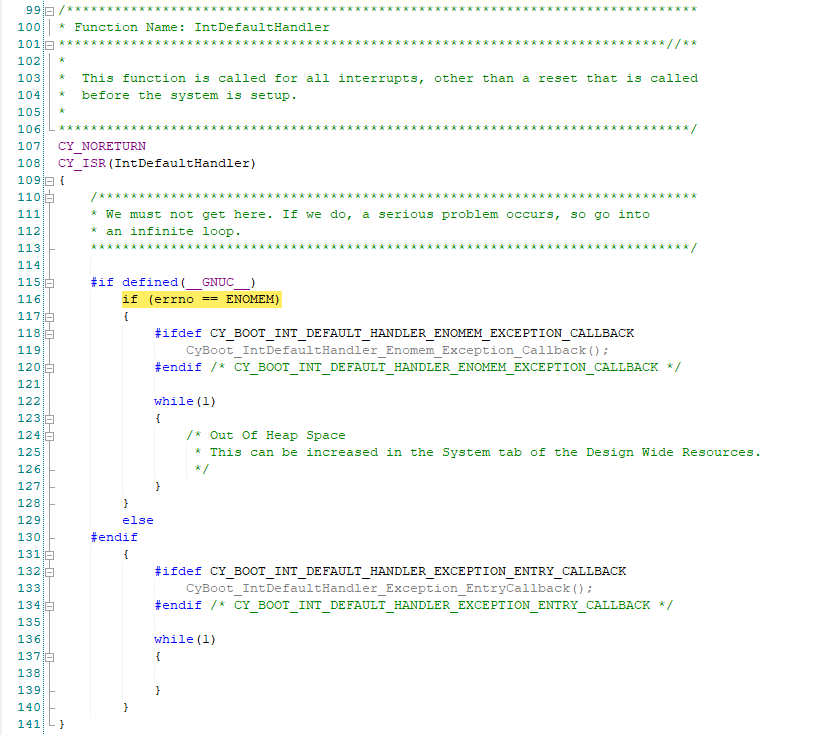

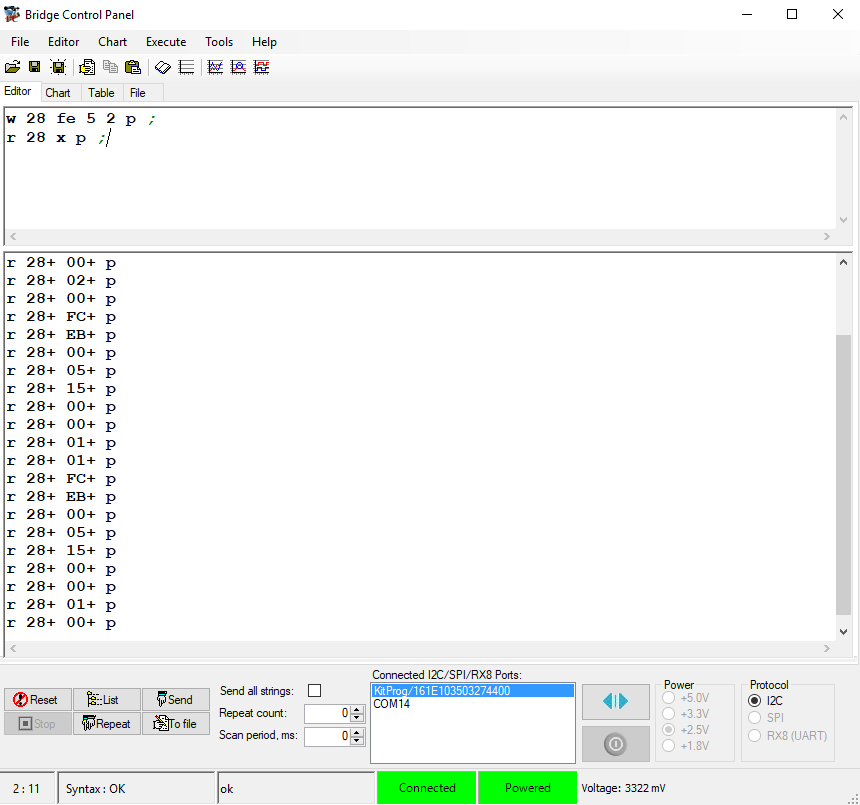

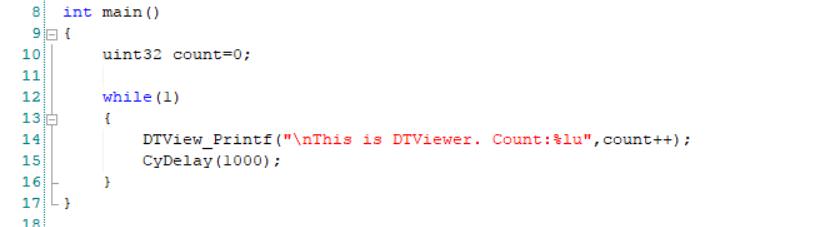

Next I need to modify the comboread_cb callback. It will

- Setup a structure to hold the three acceleration values (Line 145)

- Then it will read from the LSM9DS1 (Line 152)

- Then print them (Line 156)

/******************************************************************************

* This function reads the value from I2C slave and prints it

*****************************************************************************/

void comboread_cb (uint32_t arg)

{

UINT8 status = 0xFF;

UINT8 reg_add = 0x28; // Acceleromter register

typedef struct {

int16_t ax;

int16_t ay;

int16_t az;

} __attribute__((packed)) accel_val_t;

accel_val_t data;

status = wiced_hal_i2c_combined_read((UINT8 *)®_add, sizeof(UINT8), (uint8_t *)&data, sizeof(data), LSM9DS1_ACC_GYRO_I2C_ADDRESS);

if(I2CM_SUCCESS == status) {

WICED_BT_TRACE("Ax=%d Ay=%d Az=%d\n",data.ax,data.ay,data.az);

}else if(I2CM_OP_FAILED == status) {

WICED_BT_TRACE("I2C comboread operation failed\r\n");

}else if(I2CM_BUSY == status) {

WICED_BT_TRACE("I2C busy\r\n");

}else{

WICED_BT_TRACE("Unknown status from I2C\r\n");

}

}

Now double click the make target and make sure that everything is working.