Summary

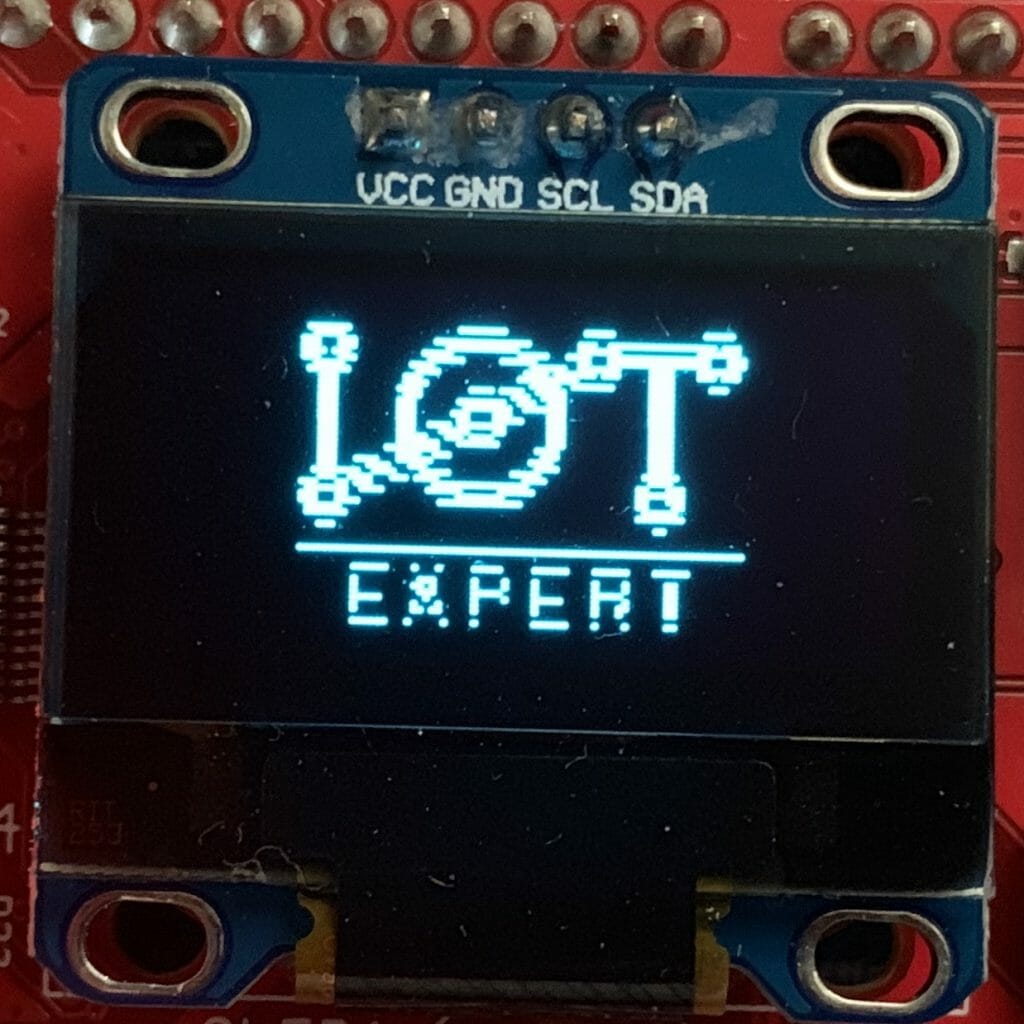

This article explains in detail how to use and debug SSD1306 displays. In this article, I use the Segger emWin library and MBEDOS, but for all practical purposes this discussion applies to all other interfaces to the board including Arduino, Raspberry Pi, Adafruit, etc. I will say from the outset that I spent far far too much time digging into the inner workings of an 11 year old graphics driver. Oh well, hopefully someone will get some benefit.

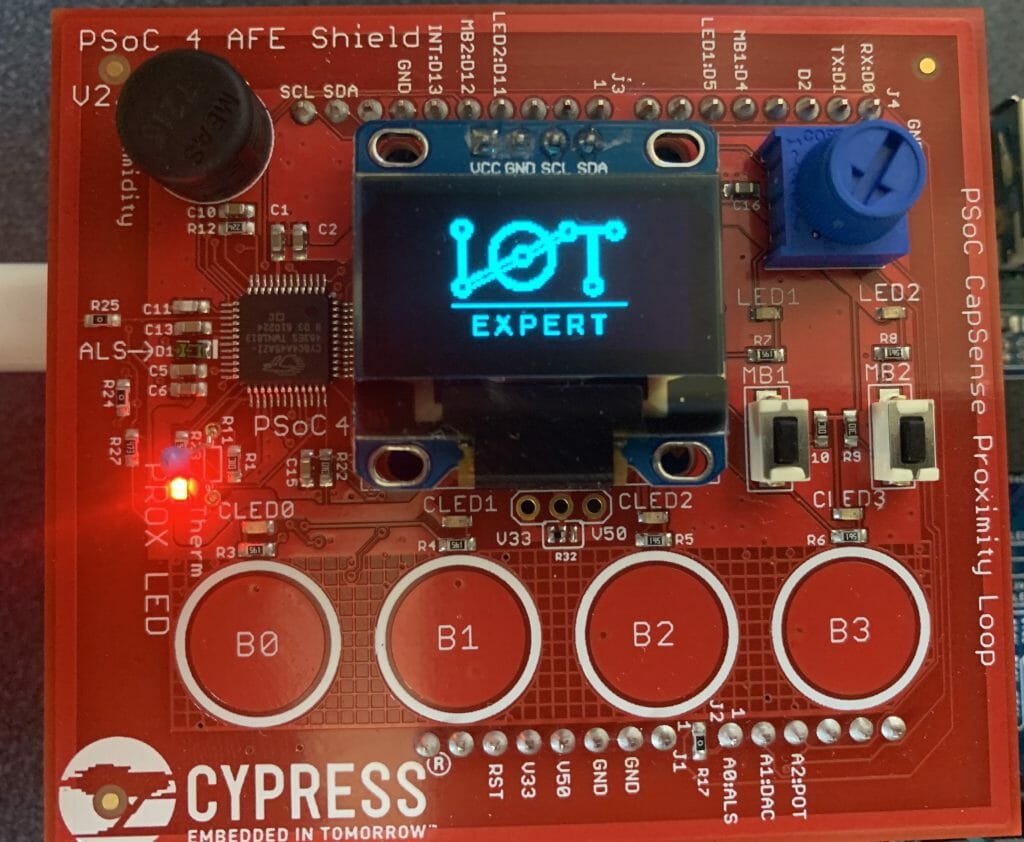

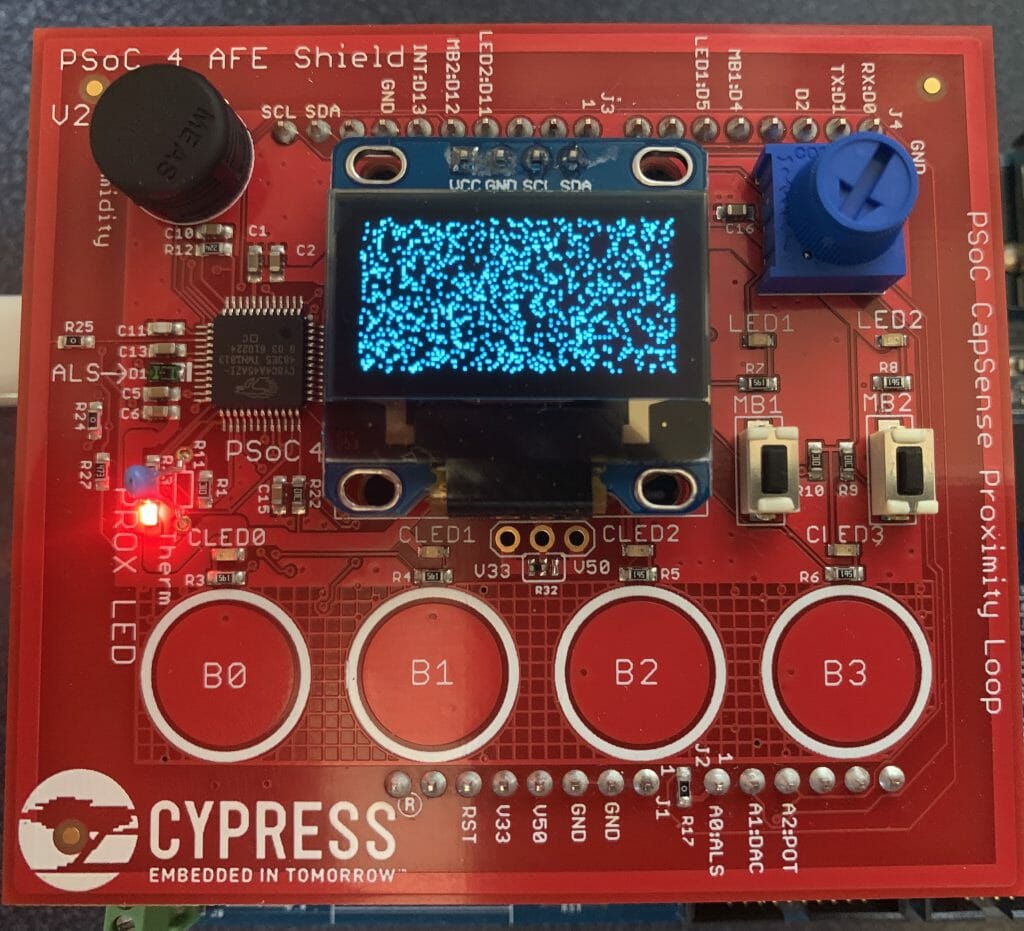

A year ago (or so) I designed a user interface board called the CY8CKIT-032 to go with my Cypress WICED WiFi book and class. This board uses a PSoC 4 Analog co-processor which can do a bunch of cool stuff. I have a series of articles planned about that board, but that will be for another day. One of the things that I did was put a 0.96″ I2C OLED Display based on a SSD1306 driver on the board. These displays are widely available from Alibaba and eBay for <$2. I think that the displays are being used in inexpensive cells phones in China so there are tons of them and they are CHEAP! The bad news is that if you google “ssd1306 problems” you will find an absolute rogues gallery of unpleasantness. It seems that tons of people struggle to get these things working.

This whole thing started last week as Cypress released and update to our MBED OS implementation. This update included releasing a complete set of the Segger emWin drivers. I had been wanting to step up to a more robust graphics library than the Adafruit library that I used in this article. I was pleased to see that our release included the emWin SPAGE driver which knows how to talk to a bunch of different page based displays including the SSD1306.

But, as always, I had to wrestle with the display a little bit before I got everything working. This time I wrote down what I did/learned. So, for this article I will describe

- The SSD1306 Electrical Interface

- The SSD1306 Software Interface

- The SSD1306 Driver Registers

- The SSD1306 Graphics Data RAM

- Reading from the Frame Buffer

- My Initialization Sequence

- Some Other Initialization Sequences

- A Bunch of Screen Problems & How To Fix

The Electrical Interface

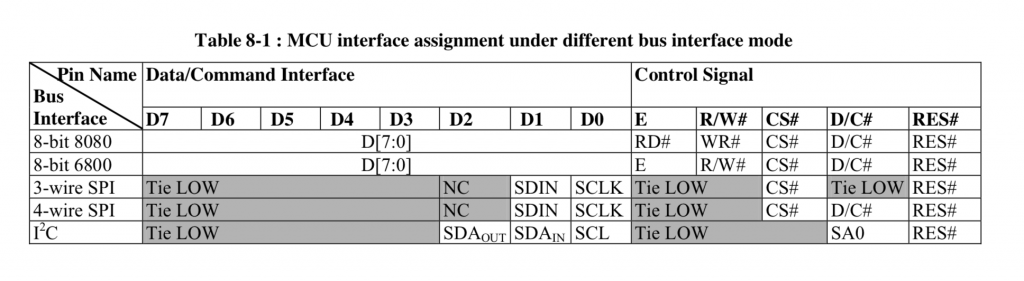

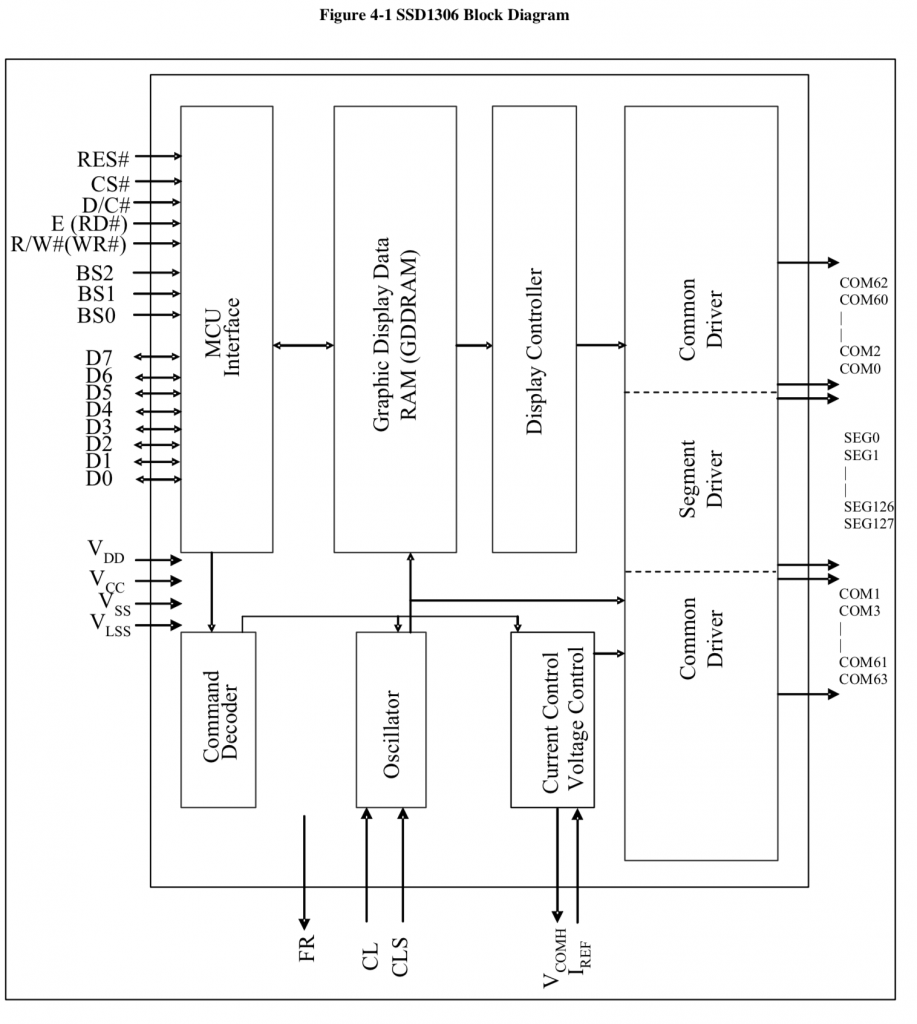

There is not a lot to know about the electrical interface. The data sheet specifies that the device can use I2C, SPI, 6800 and 8080. I have not seen either the 6800 or 8080 interface put onto any of these OLED displays. Like all driver chips, the SSD1306 has an absolute boatload of pins, in fact, 281. The chip is long and skinny and was made to be mounted either on the display under the glass or on the flex connector. Of the 281 pins, 128+64=196 are connected to the segments and commons in the display. The rest of the pins are either capacitors, no-connects, power/ground or data signals. The data signals are

- D0-D7 either parallel data for 8080/6800 or SDA/SCL for I2C or MOSI/MISO for SPI

- E – enable signal for 6800 or RD for 8080

- R/W# – Read Write for 6800/8080

- CS – Chip Select for SPI, 8080, 6800

- D/C# – Data or Command for SPI, 6800, 8080 or Slave Address Select for I2C

- Reset – Chip reset

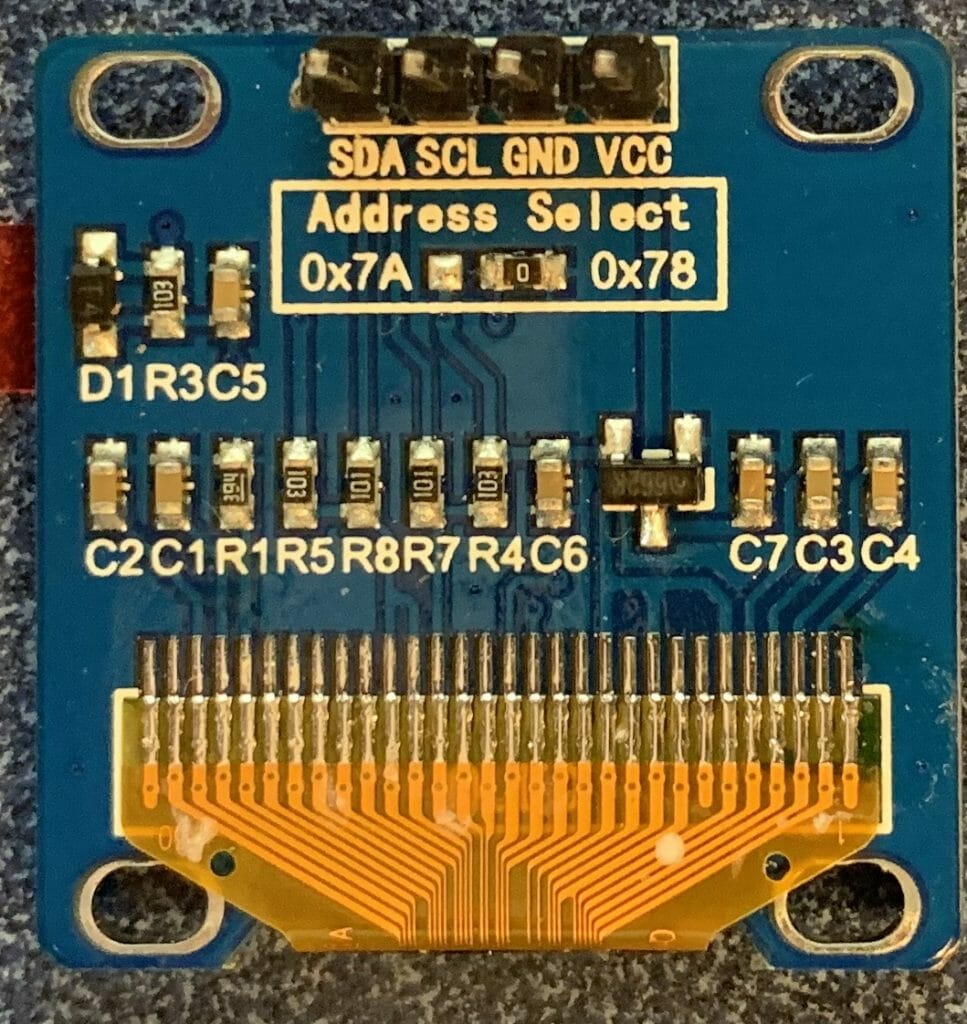

For the I2C configurations it is common to tie the reset pin High and not bring the pin to a connector. The SA0 is also typically connected via a 0-ohm resistor to either 0 or 1 which configures the device to have the 7-bit address 0x3C or 0x3D or 8-bit 0x78 or 0x7A. Here is a picture of the back of one of my boards where you can see the 0ohm resistor.

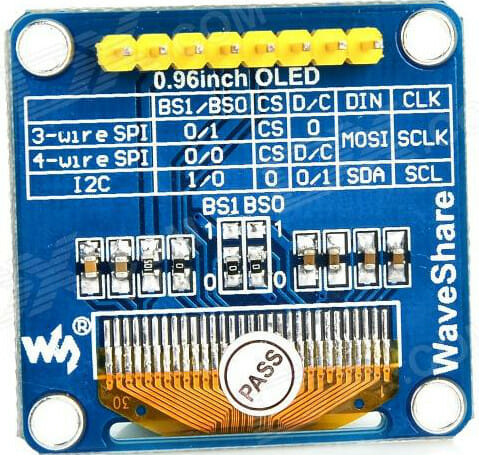

Sometimes all of the data pins are available on the back of the board. This lets you move/add/change the 0-ohm resistors to configure the mode of the chip.

One thing you should be careful about is the I2C connections. I looked around on eBay and Alibaba to find a few pictures of the I2C displays. You should notice that all three of these displays are I2C, but all three of them have a different position and ORDER of VCC/GND/SCL/SDL When we ordered displays from China to go onto the CY8CKIT-032 we found displays in the same BATCH that had different orders of the VCC/GND.

Here is a SPI version that has reset and data/command pin brought out.

The Software Interface

There are two parts to the software interface.

The first part is the command interface. Inside of the chip there are a bunch of logic circuits which which configure the charge pumps, sequence COMs and SEGs, charge and discharge capacitors etc. All of these things are configurable to allow for different configurations of screens e.g. different x-y sizes, configuration of what wires are connected to what places on the glass etc. Before you can get the display to work correctly you must initialize all of these values by sending commands. All the commands are 1-byte followed by 0 or more command parameters.

The second part is the data interface. Inside of the SSD1306 chip there is a Graphics Display DRAM – GDDRAM which has 1 bit for every pixel on the screen. The state machine inside of the chip called the Display Controller will loop through the bits one by one and display them on the correct place on the screen. This means that your MCU does not need to do anything to keep the display up to date. When you want a pixel lit up on the screen you just need to write the correct location in the GDDRAM.

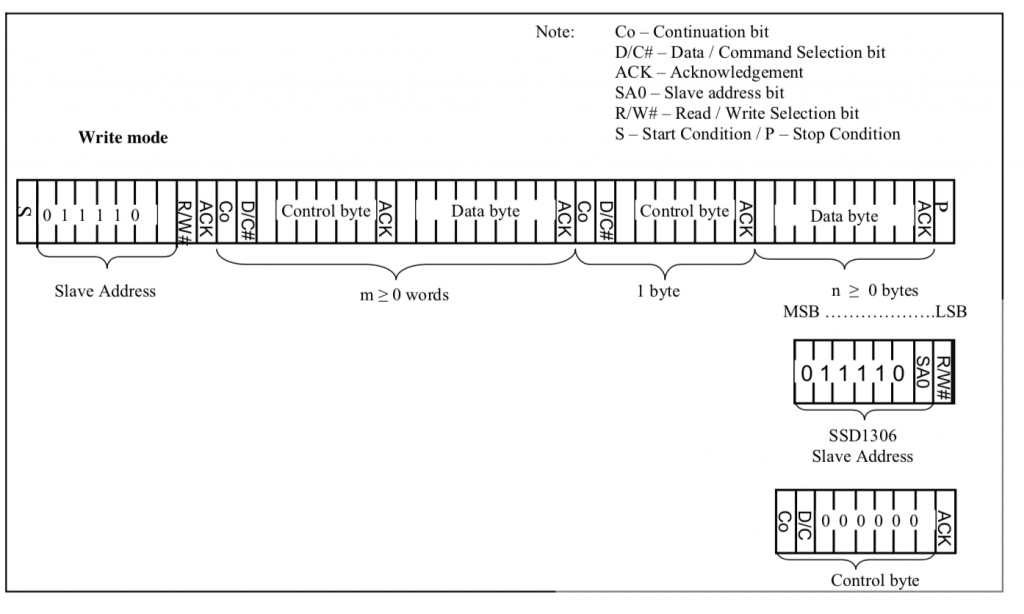

For the rest of this article I will focus on the serial interface, I2C. How do you send commands and data? Simple. When you start a transaction you send a control byte which tells the controller what to expect next. There are four legal control bytes.

- 0b10000000 = 0x80 = multiple commands

- 0b00000000 = 0x00 = one command

- 0b11000000 = 0xC0 = multiple data

- 0b01000000 = 0x40 = one data byte

Here is the picture from the datasheet (which I don’t find particularly illuminating) but it does describe the control byte.

To send commands you write to the I2C bus with a control byte, then you send the command, then you send the optional parameters. If you want to send multiple commands you send the control byte 0x80, the command + parameters as many as you need.

The SSD1306 Driver Registers

In order for the driver chip to drive the screen you need to configure:

- How the driver is electrically connected to the OLED Screen

- What are the electrical parameters of the screen

- What are the electrical parameters of the system

- How you want to address the frame buffer

- The automatic scroll configuration settings

- The pixel data for the frame buffer, though it will happily display noise.

If you bought this screen from eBay, Adafruit, Alibaba etc. then you will get no say in 1-3, the electrical parameters of the system. Your screen will come prewired with all of the capacitors, OLED etc already attached to your driver commons and segments. If you didn’t buy the screen prepackaged, then it is highly unlikely you are reading this article. What this means is that you need to know the initializing sequence required to get the screen to work properly, then you just send the sequence down the wire from your MCU to the screen. From looking around on the internet, it appears to me that there in only one parameter that is different in any of the screens that I could find. Specifically the number of lines on the screen – either 32 or 64. Which means that all of these initialization implementations should really on have one difference register 0xA8 should be set to either n-1 aka 31 or 63

The other difference that you will see between different implementations is the memory address mode. In other words, how do you want to write data into the frame buffer from the MCU. Many of the open source graphics libraries use “Horizontal” mode. The Segger emWin library that I am using uses “Page” mode. More on this later.

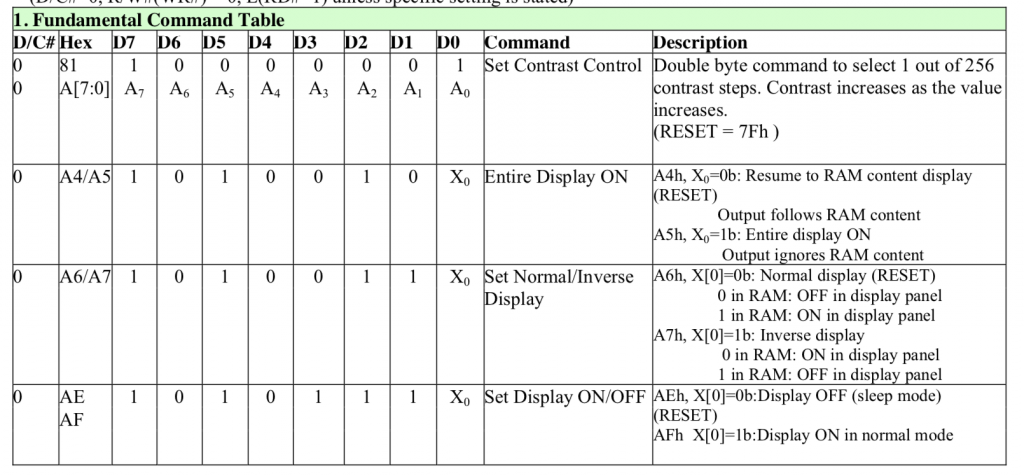

When you look in the data sheet, unfortunately they mix and match the order of the information. However, from the data sheet, the categories are:

- Fundamental Commands

- Scrolling Commands

- Address Setting Commands

- Hardware Configuration

- Timing and Driving Scheme

- Charge Pump

I won’t put screen shots of the whole data sheet into this article, but I will show the command table and make a few clarifications on the text. Or at least I will clarify places where I got confused.

As to the fundamental commands. I tried a bunch of different contrast settings on my screens and could not tell the difference between them. I tried from 0x10 to 0xFF and they all looked the same to me. The best course of action is to use the default 0x7F. I don’t really know why there is a command 0xA5 “Entire Display ON ignore RAM”. The data sheet says “A5h command forces the entire display to be “ON”, regardless of the contents of the display data RAM”. I can’t think of a single use case for this. I suppose that if you issue 0xAE the screen will be all black… and if you issue 0xA5 the screen will be all white? But why?

And my definitions in the C driver file:

//////////////////////////////////////////////////////////////////////// // Fundamental Command Table Page 28 //////////////////////////////////////////////////////////////////////// #define OLED_SETCONTRAST 0x81 // 0x81 + 0-0xFF Contrast ... reset = 0x7F // A4/A5 commands to resume displaying data // A4 = Resume to RAM content display // A5 = Ignore RAM content (but why?) #define OLED_DISPLAYALLONRESUME 0xA4 #define OLED_DISPLAYALLONIGNORE 0xA5 // 0xA6/A7 Normal 1=white 0=black Inverse 0=white 1=black #define OLED_DISPLAYNORMAL 0xA6 #define OLED_DISPLAYINVERT 0xA7 // 0xAE/AF are a pair to turn screen off/on #define OLED_DISPLAYOFF 0xAE #define OLED_DISPLAYON 0xAF

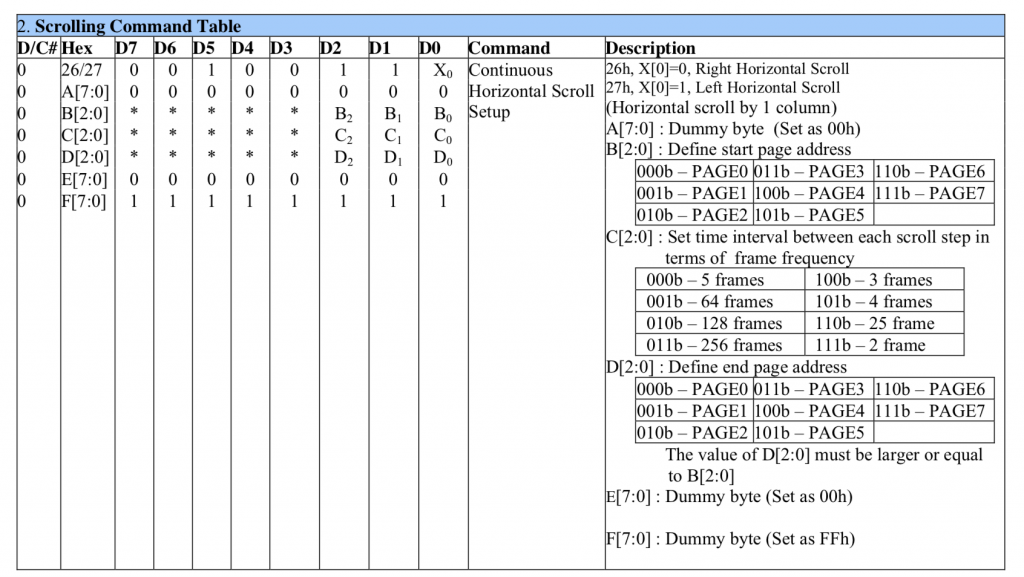

In the next section of the command table are the “Scrolling” commands. It appears that this graphics chip was setup to display text that is 8-pixels high. The scrolling commands will let you move the screen up/down and left/right to scroll automatically without having to update the the frame buffer. In other words it can efficiently scroll the screen without a bunch of load on your MCU CPU or on the data bus between them. The Adafruit graphics library provides the scrolling commands. However, I am not using them with the Segger Library.

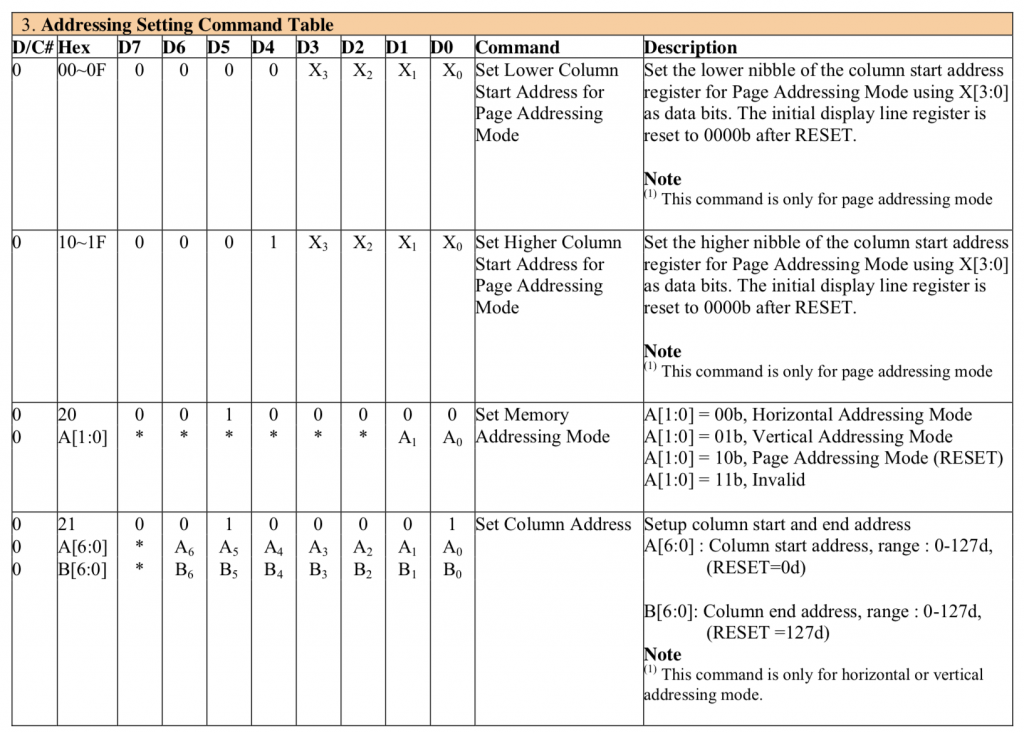

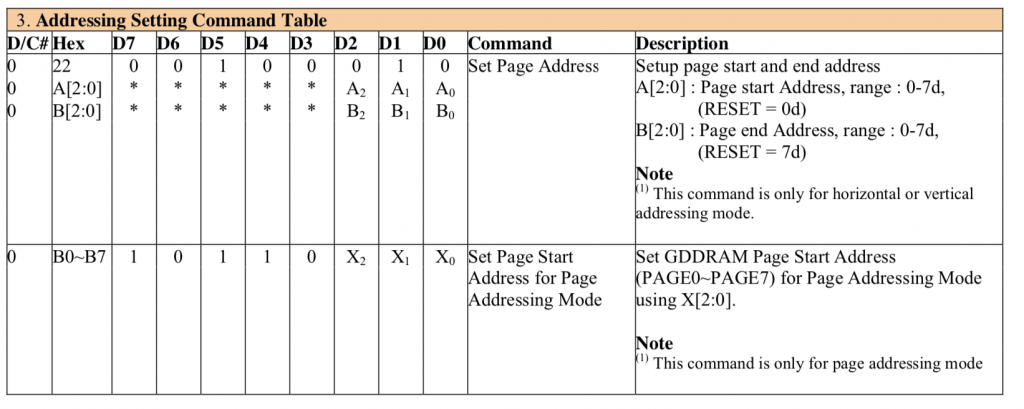

The next section has the commands to configure how your MCU writes data into the Graphics RAM aka the frame buffer. These commands fall into two categories. First the address mode. The address modes help you efficiently write the GDDRAM. When you send data to the frame buffer you really don’t want to send

- address, pixel, address, pixel, …

What you really would like to do is send

- Address, pixel, pixel, pixel … (and have the address be automatically incremented

At first blush you might think… why do I need a mode? Well there are some people who want the x address incremented… there are some people who want the y-address incremented and there are some people who want to have page address access. And what do you do when you get to the end of a line? or a column or a page? and what does the end mean?

The second set of commands in this table are the commands to set the starting address before you write data.

//////////////////////////////////////////////////////////////////////// // Address Setting Command Table //////////////////////////////////////////////////////////////////////// // 00-0F - set lower nibble of page address // 10-1F - set upper niddle of page address #define OLED_SETMEMORYMODE 0x20 #define OLED_SETMEMORYMODE_HORIZONTAL 0x00 #define OLED_SETMEMORYMODE_VERTICAL 0x01 #define OLED_SETMEMORYMODE_PAGE 0x02 // 0x20 + 00 = horizontal, 01 = vertical 2= page >=3=illegal // Only used for horizonal and vertical address modes #define OLED_SETCOLUMNADDR 0x21 // 2 byte Parameter // 0-127 column start address // 0-127 column end address #define OLED_SETPAGEADDR 0x22 // 2 byte parameter // 0-7 page start address // 0-7 page end Address // 0xB0 -0xB7 ..... Pick page 0-7

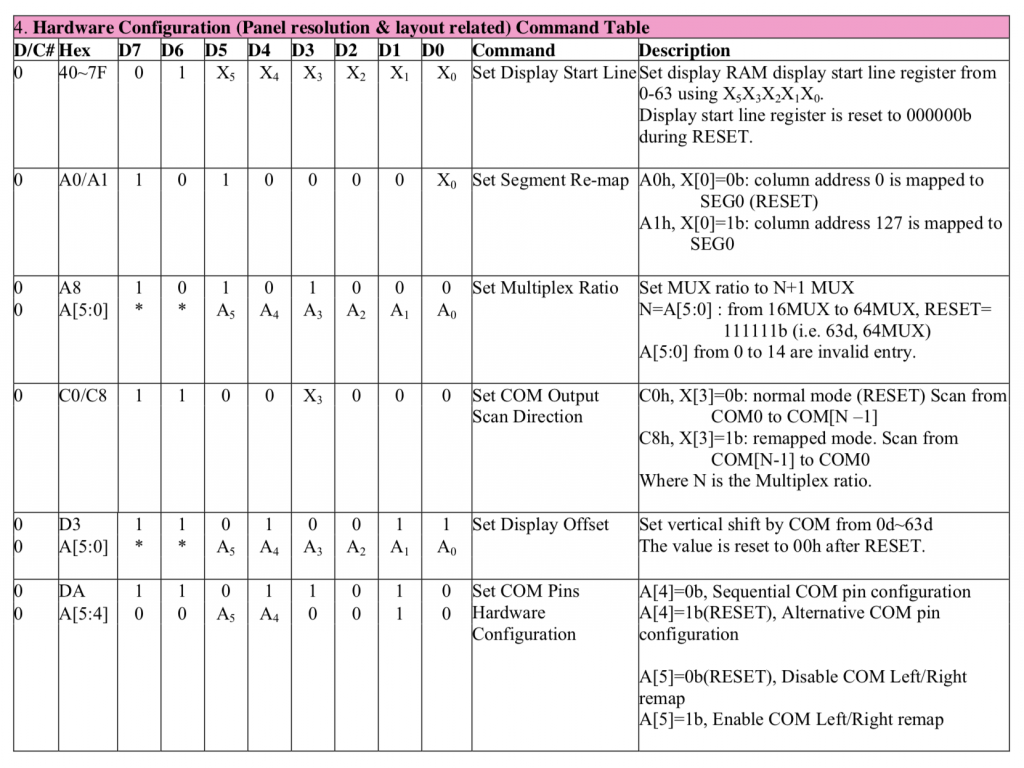

The hardware configuration registers allow the LED display maker to hookup the common and segment signals in an order that makes sense for the placement of the chip on the OLED glass. For a 128×64 display there are at least 196 wires, so the routing of these wires may be a total pain in the ass depending on the location of the chip. For instance the left and right might be swapped… or half the wires might come out on one side and the other half on the other side. These registers allow the board designer flexibility in making these connections. Commands 0xA0, 0xA1, 0xA8, 0xC0, 0xC8, 0xD3, 0xDa will all be fixed based on the layout. You have no control and they need to be set correctly or something crazy will come out.

//////////////////////////////////////////////////////////////////////// // Hardware Configuration //////////////////////////////////////////////////////////////////////// // 40-7F - set address startline from 0-127 (6-bits) #define OLED_SETSTARTLINE_ZERO 0x40 // Y Direction #define OLED_SEGREMAPNORMAL 0xA0 #define OLED_SEGREMAPINV 0xA1 #define OLED_SETMULTIPLEX 0xA8 // 0xA8, number of rows -1 ... e.g. 0xA8, 63 // X Direction #define OLED_COMSCANINC 0xC0 #define OLED_COMSCANDEC 0xC8 // double byte with image wrap ...probably should be 0 #define OLED_SETDISPLAYOFFSET 0xD3 // Double Byte Hardware com pins configuration #define OLED_SETCOMPINS 0xDA // legal values 0x02, 0x12, 0x022, 0x032

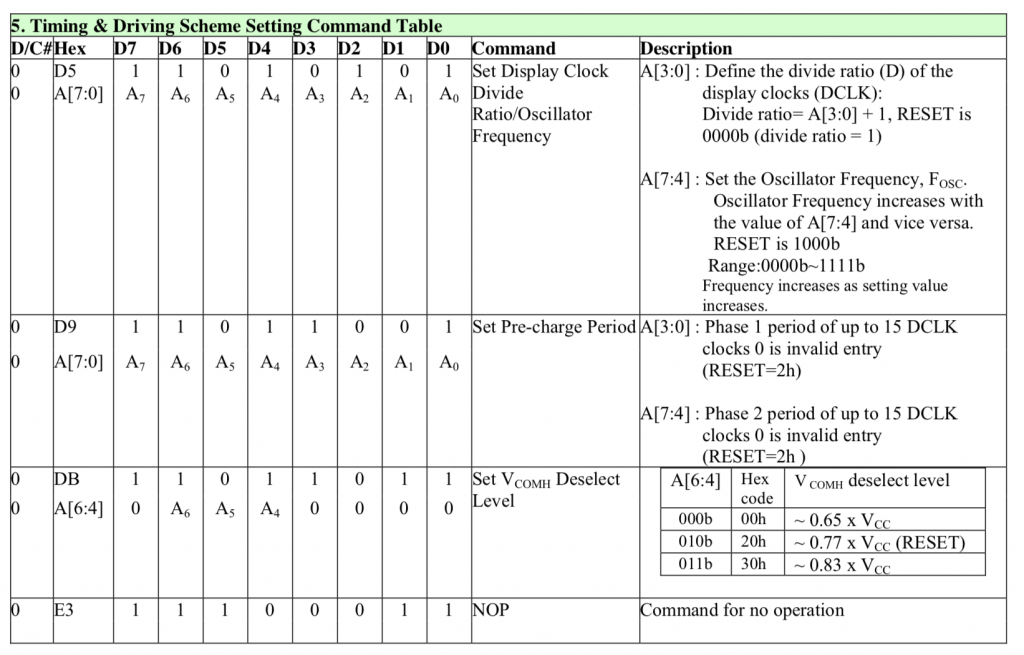

The next sections of commands are part of the electrical configuration for the glass.

0xD5 essentially sets up the display update rate by 1) setting the display update clock frequency and 2) setting up a divider for that clock.

0xDB and 0xD9 sets up a parameter that is display dependent. That being said I tried a bunch of different values and they all look the same to me.

//////////////////////////////////////////////////////////////////////// // Timing and Driving Scheme Settings //////////////////////////////////////////////////////////////////////// #define OLED_SETDISPLAYCLOCKDIV 0xD5 #define OLED_SETPRECHARGE 0xD9 #define OLED_SETVCOMDESELECT 0xDB #define OLED_NOP 0xE3

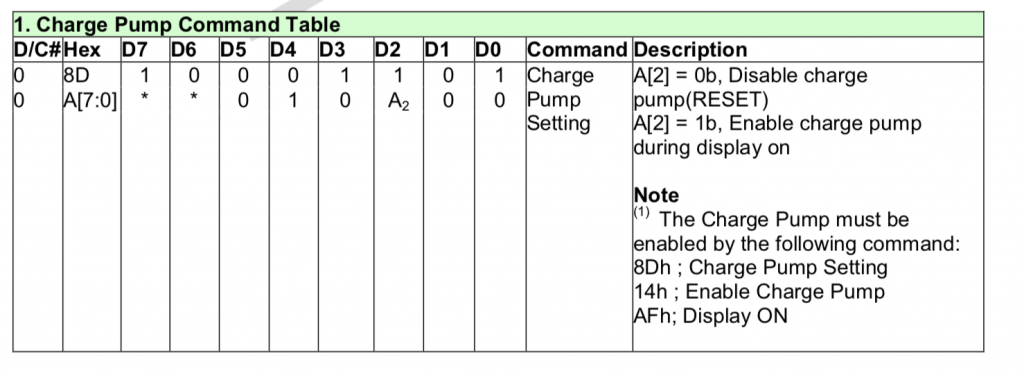

These displays require a high voltage to program the liquid crystal in the display. That voltage can either be supplied by an external pin or by an internal charge pump. All the displays that I have seen use an internal charge pump.

//////////////////////////////////////////////////////////////////////// // Charge Pump Regulator //////////////////////////////////////////////////////////////////////// #define OLED_CHARGEPUMP 0x8D #define OLED_CHARGEPUMP_ON 0x14 #define OLED_CHARGEPUMP_OFF 0x10

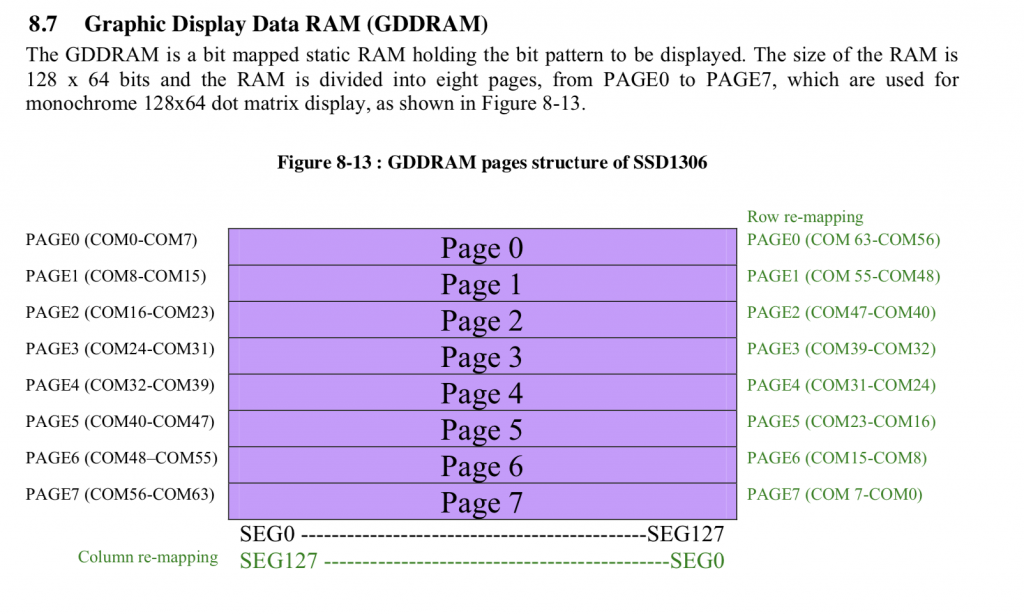

The SSD1306 Graphics Data RAM

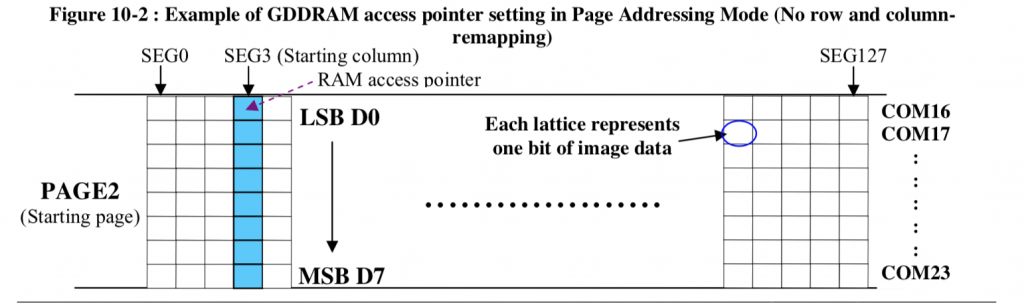

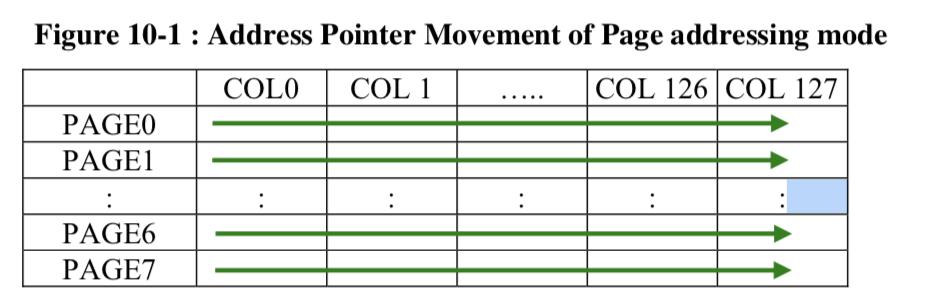

In order to actually get data to display on the screen you need to write 1’s and 0’s into the Graphics Data RAM that represents your image. The memory is actually organized into 8 pages that are each 128 bits wide and 8 bits tall. This means that if you write 0b10101010 to location (0,0) you will get the first 8 pixels in a column on the screen to be on,off,on,off,on,off,on,off. Notice that I said vertical column and not row. Here is a picture from the data sheet. That shows the pages:

And then they show you in the data sheet that the pixels go down from the first row of the page.

In order to make the writing process easier and lower bandwidth the SSD1306 has three automatic addressing modes.

- Horizontal – Set the page address start, end and the column start and end… bytes write 8 vertical pixels on the page. Each byte write advances the column until it wraps to the next page and resets the column to the “start”

- Vertical – Set the page address start, end and the column start and end… bytes write 8 vertical pixels on the page. Each byte write advances the page until it wraps vertically where it increments the column and resets the page back to the start page.

- Page – Set the page address and column start/end. Each byte writes vertically. Wraps back onto the same page when it hits the end column.

In Horizontal and Vertical mode you

- Set the range of columns that you want to write (using 0x22)

- Set the range of pages you want to write (using 0x21)

- Write bytes

In the page mode you

- Set the page (remember you can only write one page at a time in page mode) using 0xB0-0xB7

- Set the start column using 0x0? and 0x1?

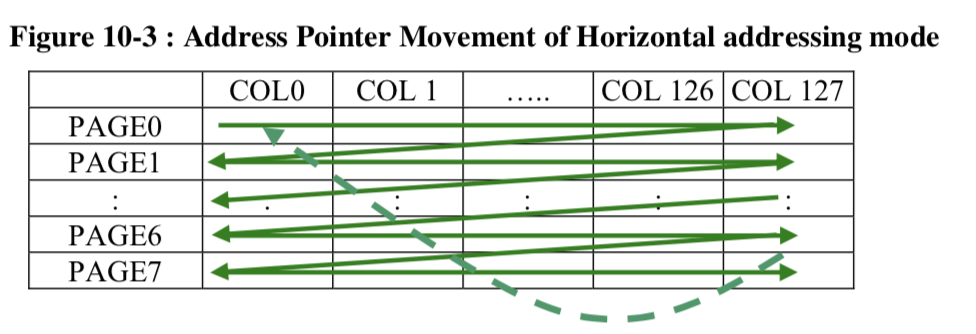

Here is a picture from the data sheet of horizontal address mode:

In this bit of example code I am saying to iterate through the pages 0->7… in other words all of the pages. And to start in column 0. This example will make 12 columns of pixels each 8 high starting a (0,0) on the screen…

char horizontalExample[]= {

0xAE,

0x20, /// address mode

0x00, // Horizontal

0xA4,

0xAF,

0x22, //Set page address range

0,

7,

0x21, // column start and end address

0,

127,

};

I2C_WriteCmdStream(horizontalExample, sizeof(horizontalExample));

// Write twelve bytes onto screen with 0b10101010

for(int i=0;i<12;i++)

I2C_WriteData(0xAA);

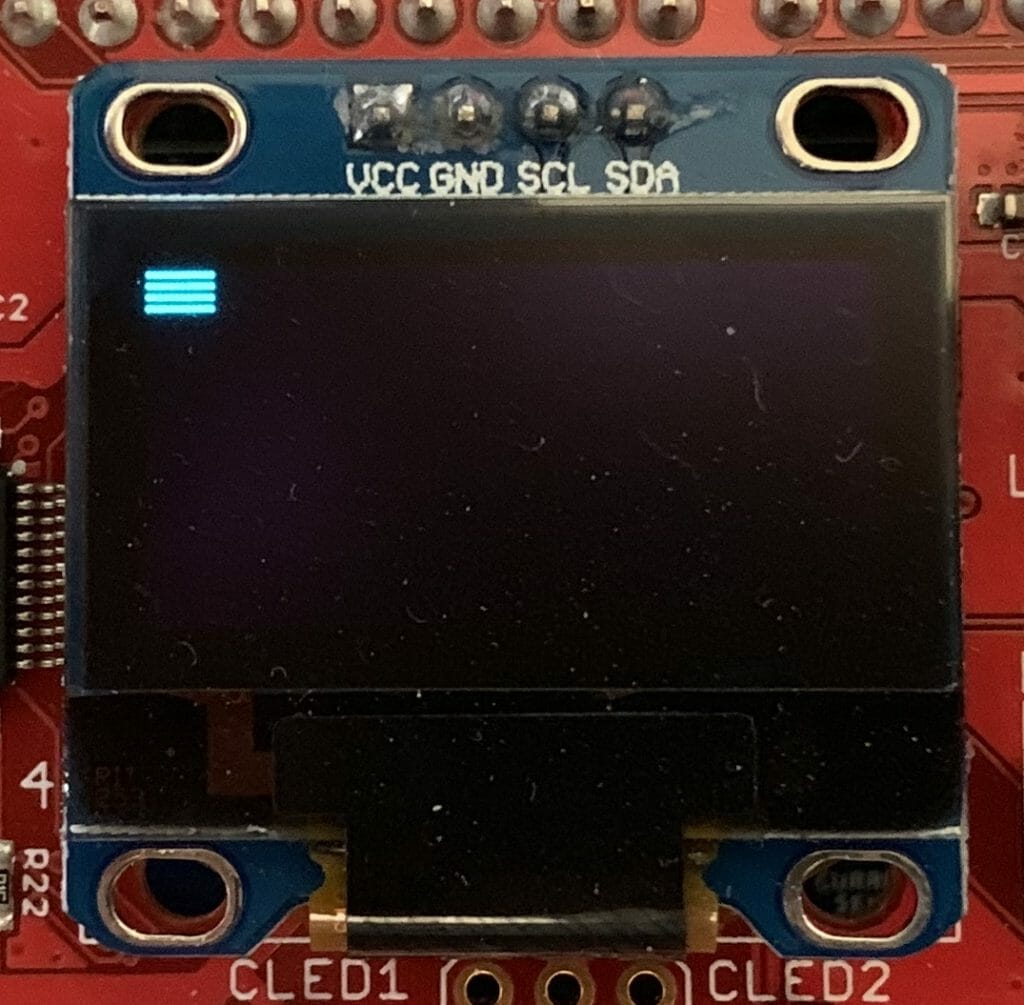

Here is a picture of what it does.

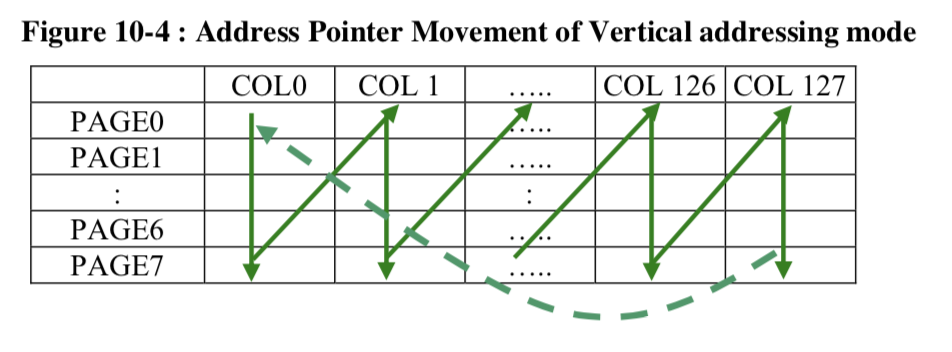

Here is a picture from the data sheet of vertical address mode:

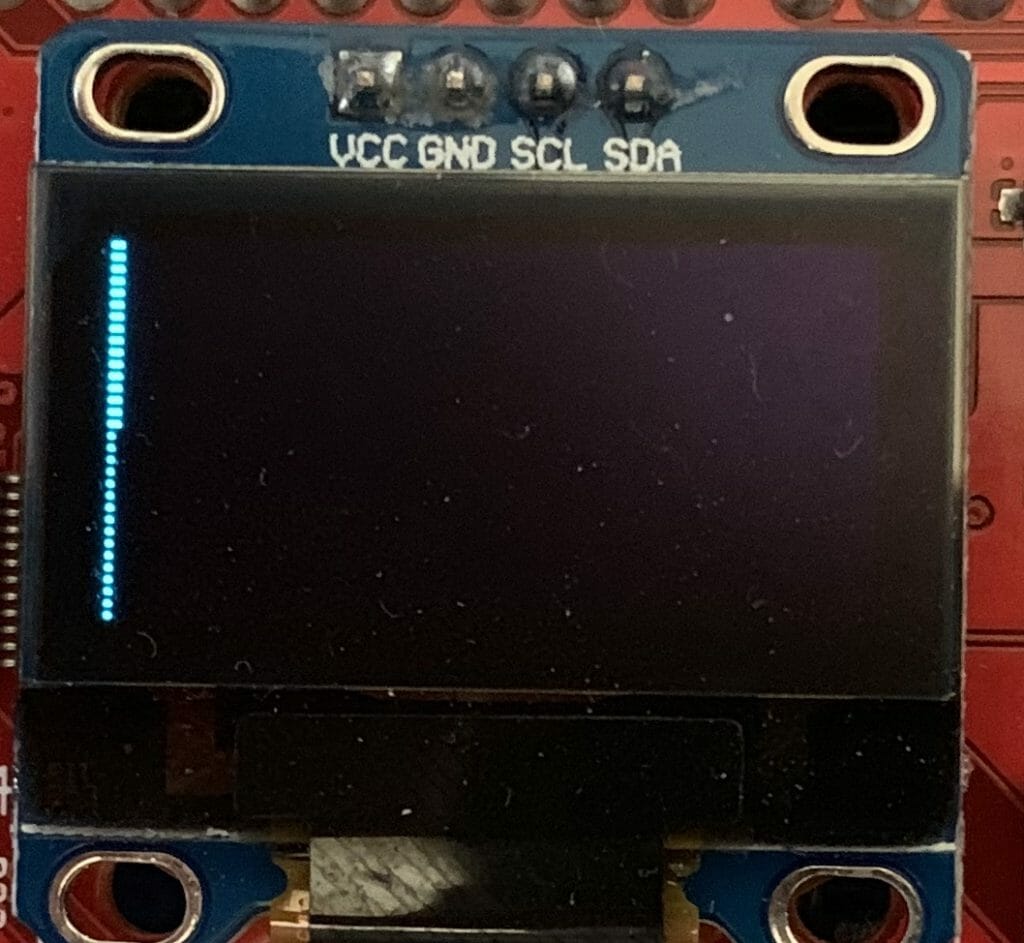

This example code sets the page range to 0–>7 (the whole screen) and the column range 0–>127 (the whole screen). Then writes 12 bytes. You can see it wrap at the bottom and move back to page 0 column 1.

char verticalExample[]= {

0xAE,

0x20, /// address mode

0x01, // vertical

0xA4,

0xAF,

0x22, //Set page address range

0,

7,

0x21, // column start and end address

0,

127,

};

I2C_WriteCmdStream(verticalExample, sizeof(verticalExample));

// Write twelve bytes onto screen with 0b10101010

for(int i=0;i<12;i++)

I2C_WriteData(0xAA);

In page mode you just set the page and the start and end column. 0xB0 means page 0, 0xB1 means page 1… 0xB7 means page 7.

You can see that I started from column 0x78 (meaning column 120) and that it wraps back to column 0 on the SAME page.

char pageExample[]= {

0xAE,

0x20, // address mode

0x02, // Page mode

0xA4, // Resume from ram

0xAF, // Screen on

0xB0, // Start from page 0

// Start from column 0x78 aka 120

0x08, // Column lower nibble address

0x17 // Column upper nibble address

};

I2C_WriteCmdStream(pageExample, sizeof(pageExample));

// Write twelve bytes onto screen with 0b10101010

for(int i=0;i<12;i++)

I2C_WriteData(0xAA);

Here is what it looks like.

Reading from the Frame Buffer

Now that you know how to write to the Frame Buffer, the next question is how do you read? For instance if you want to turn on 1 pixel (of a byte) but leave the others alone can you do this? The answer is NO. In serial mode the device only writes. In all of the Graphics libraries that I have seen they handle this by having a Frame Buffer in the MCU as well. Duplicated resources… oh well.

My Initialization Sequence

I have a function that writes an array of bytes to the command registers. So for me to initialize the screen I just need to set up that array. Here is my best known setup.

const char initializeCmds[]={

//////// Fundamental Commands

OLED_DISPLAYOFF, // 0xAE Screen Off

OLED_SETCONTRAST, // 0x81 Set contrast control

0x7F, // 0-FF ... default half way

OLED_DISPLAYNORMAL, // 0xA6, //Set normal display

//////// Scrolling Commands

OLED_DEACTIVATE_SCROLL, // Deactive scroll

//////// Addressing Commands

OLED_SETMEMORYMODE, // 0x20, //Set memory address mode

OLED_SETMEMORYMODE_PAGE, // Page

//////// Hardware Configuration Commands

OLED_SEGREMAPINV, // 0xA1, //Set segment re-map

OLED_SETMULTIPLEX, // 0xA8 Set multiplex ratio

0x3F, // Vertical Size - 1

OLED_COMSCANDEC, // 0xC0 Set COM output scan direction

OLED_SETDISPLAYOFFSET, // 0xD3 Set Display Offset

0x00, //

OLED_SETCOMPINS, // 0xDA Set COM pins hardware configuration

0x12, // Alternate com config & disable com left/right

//////// Timing and Driving Settings

OLED_SETDISPLAYCLOCKDIV, // 0xD5 Set display oscillator frequency 0-0xF /clock divide ratio 0-0xF

0x80, // Default value

OLED_SETPRECHARGE, // 0xD9 Set pre-changed period

0x22, // Default 0x22

OLED_SETVCOMDESELECT, // 0xDB, //Set VCOMH Deselected level

0x20, // Default

//////// Charge pump regulator

OLED_CHARGEPUMP, // 0x8D Set charge pump

OLED_CHARGEPUMP_ON, // 0x14 VCC generated by internal DC/DC circuit

// Turn the screen back on...

OLED_DISPLAYALLONRESUME, // 0xA4, //Set entire display on/off

OLED_DISPLAYON, // 0xAF //Set display on

};

Some Other Initialization Sequences

If you look around you will find many different SSD1306 libraries. You can run this search on github.

Here is one example from https://github.com/vadzimyatskevich/SSD1306/blob/master/src/ssd1306.c This is pretty much the same as mine except that the author put them in some other order than the data sheet. I am not a huge fan of “ssd1306Command( SSD1306_SEGREMAP | 0x1)” but it does work.

void ssd1306Init(uint8_t vccstate)

{

_font = (FONT_INFO*)&ubuntuMono_24ptFontInfo;

// Initialisation sequence

ssd1306TurnOff();

// 1. set mux ratio

ssd1306Command( SSD1306_SETMULTIPLEX );

ssd1306Command( 0x3F );

// 2. set display offset

ssd1306Command( SSD1306_SETDISPLAYOFFSET );

ssd1306Command( 0x0 );

// 3. set display start line

ssd1306Command( SSD1306_SETSTARTLINE | 0x0 );

ssd1306Command( SSD1306_MEMORYMODE); // 0x20

ssd1306Command( 0x00); // 0x0 act like ks0108

// 4. set Segment re-map A0h/A1h

ssd1306Command( SSD1306_SEGREMAP | 0x1);

// 5. Set COM Output Scan Direction C0h/C8h

ssd1306Command( SSD1306_COMSCANDEC);

// 6. Set COM Pins hardware configuration DAh, 12

ssd1306Command( SSD1306_SETCOMPINS);

ssd1306Command( 0x12);

// 7. Set Contrast Control 81h, 7Fh

ssd1306Command( SSD1306_SETCONTRAST );

if (vccstate == SSD1306_EXTERNALVCC) {

ssd1306Command( 0x9F );

} else {

ssd1306Command( 0xff );

}

// 8. Disable Entire Display On A4h

ssd1306Command( SSD1306_DISPLAYALLON_RESUME);

// 9. Set Normal Display A6h

ssd1306Command( SSD1306_NORMALDISPLAY);

// 10. Set Osc Frequency D5h, 80h

ssd1306Command( SSD1306_SETDISPLAYCLOCKDIV);

ssd1306Command( 0x80);

// 11. Enable charge pump regulator 8Dh, 14h

ssd1306Command( SSD1306_CHARGEPUMP );

if (vccstate == SSD1306_EXTERNALVCC) {

ssd1306Command( 0x10);

} else {

ssd1306Command( 0x14);

}

// 12. Display On AFh

ssd1306TurnOn();

}

Here is another example from git@github.com:lexus2k/ssd1306.git

https://github.com/lexus2k/ssd1306/blob/master/src/lcd/oled_ssd1306.c

Honestly if I had found this originally I would not have gone to all the trouble.

static const uint8_t PROGMEM s_oled128x64_initData[] =

{

#ifdef SDL_EMULATION

SDL_LCD_SSD1306,

0x00,

#endif

SSD1306_DISPLAYOFF, // display off

SSD1306_MEMORYMODE, HORIZONTAL_ADDRESSING_MODE, // Page Addressing mode

SSD1306_COMSCANDEC, // Scan from 127 to 0 (Reverse scan)

SSD1306_SETSTARTLINE | 0x00, // First line to start scanning from

SSD1306_SETCONTRAST, 0x7F, // contast value to 0x7F according to datasheet

SSD1306_SEGREMAP | 0x01, // Use reverse mapping. 0x00 - is normal mapping

SSD1306_NORMALDISPLAY,

SSD1306_SETMULTIPLEX, 63, // Reset to default MUX. See datasheet

SSD1306_SETDISPLAYOFFSET, 0x00, // no offset

SSD1306_SETDISPLAYCLOCKDIV, 0x80,// set to default ratio/osc frequency

SSD1306_SETPRECHARGE, 0x22, // switch precharge to 0x22 // 0xF1

SSD1306_SETCOMPINS, 0x12, // set divide ratio

SSD1306_SETVCOMDETECT, 0x20, // vcom deselect to 0x20 // 0x40

SSD1306_CHARGEPUMP, 0x14, // Enable charge pump

SSD1306_DISPLAYALLON_RESUME,

SSD1306_DISPLAYON,

};

Debug: Test the Hardware

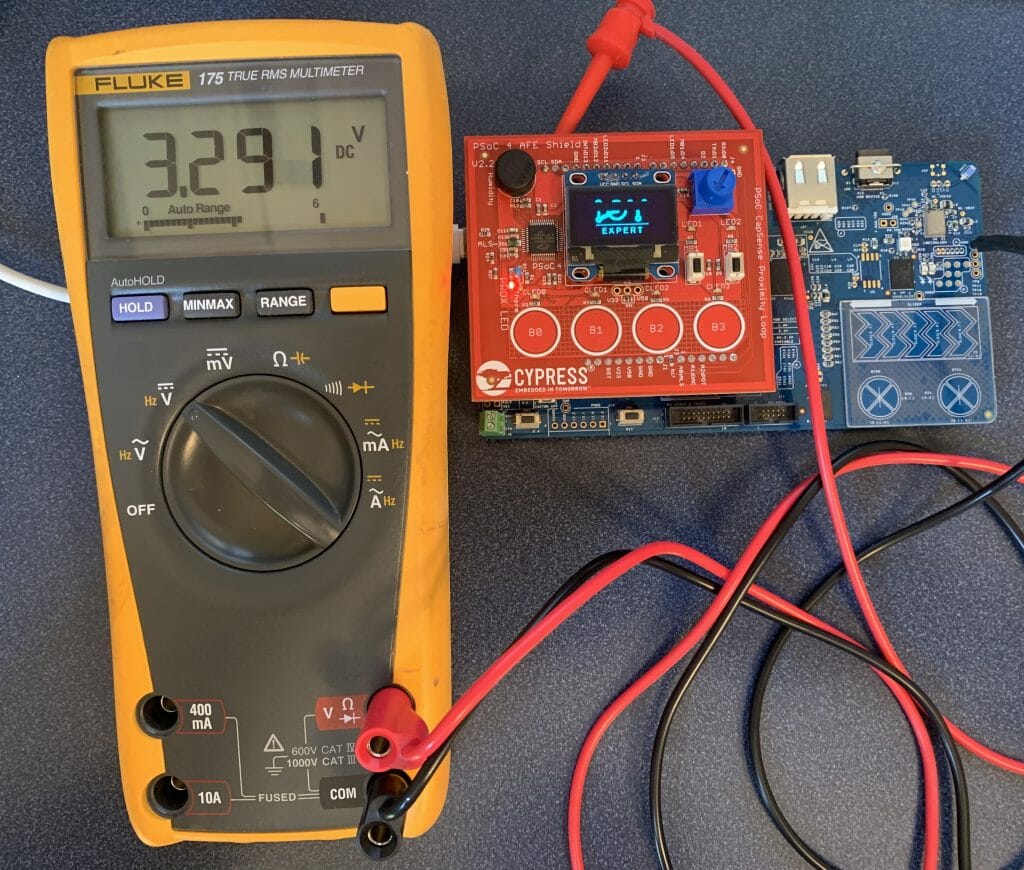

If a your screen is not working, the first thing to do is use a multimeter and make sure that VCC=SCL=SDA=3.3V. (in the picture below my camera caught the screen refresh partially through… It looks fine at normal speed). I have the red probe attached to the SCL.

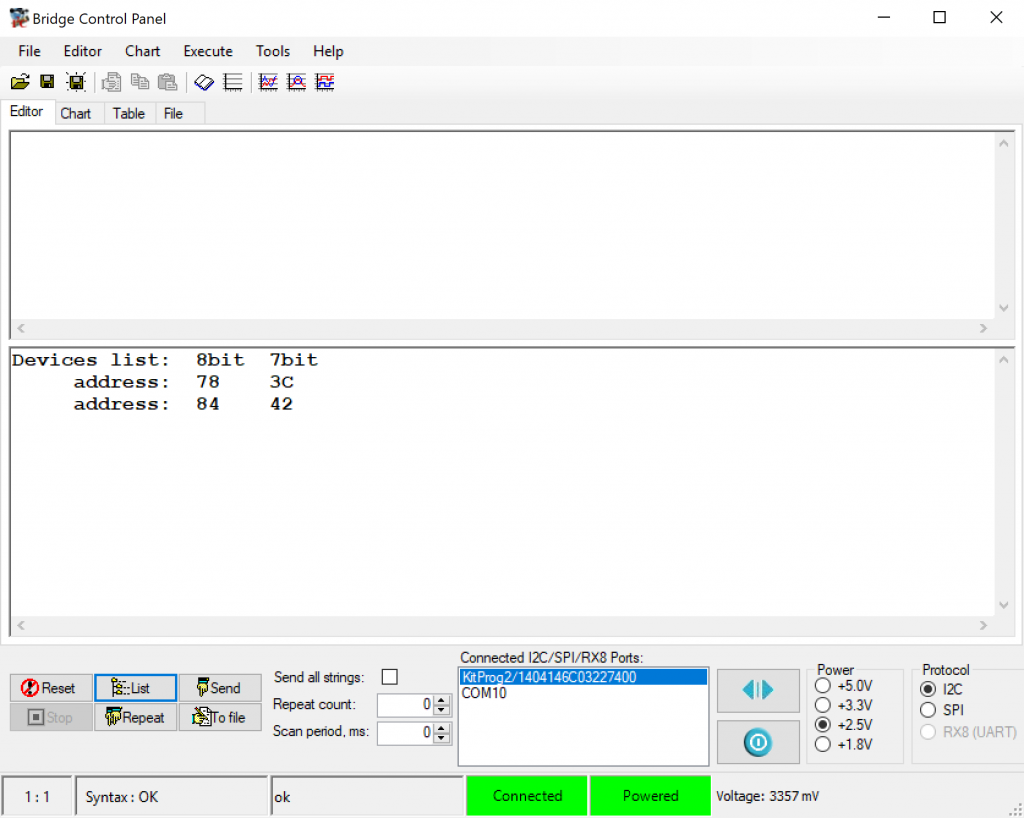

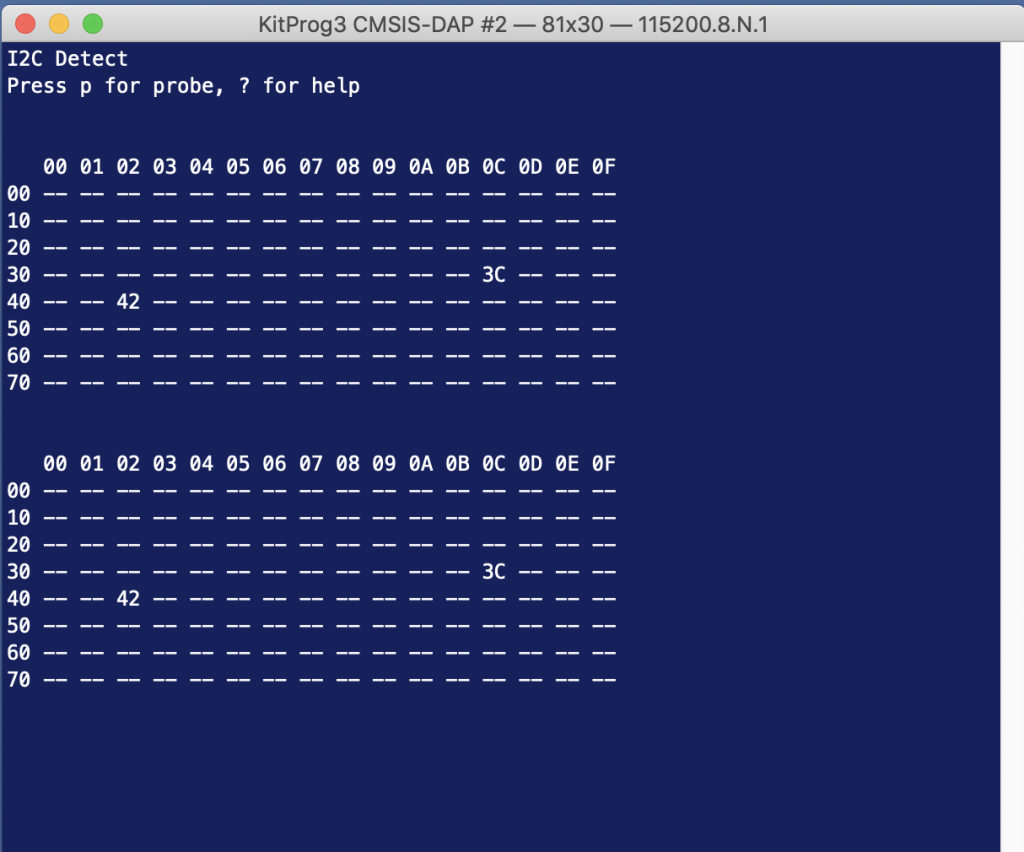

I would then run the bridge control panel and make sure that the device is responding. You can do this by pressing “List”. In the picture below you can see that there are two devices attached to the bus, my screen is set to 0x78/0x3C.

If you don’t have the bridge control panel then you can implement I2Cdetect using your development kit. Read about it here.

The next thing to do is attach a logic analyzer and make sure that the startup commands are coming out of your MCU correctly. Notice that the 00, 0xAE, 0x81… are exactly the configuration sequence that I wrote in the driver code above.

Debug: Test the Firmware

If your screen is still not working here are some problems and what to do about them.

- Speckled Screen

- Solid Screen

- Screen Flipped in the Y direction

- Screen Flipped in the X Direction

- Screen Flipped in both Directions

- Screen is Inverted

- Image is Partially off the Screen

- Image is Wrapped on the Screen

- Black Screen

- Screen Has Gone Crazy

Speckled Screen

If you have the speckled screen this means that your screen is displaying an uninitialized frame buffer which the SSD people call the GDDRAM. These are basically the random 0 and 1s that are the startup values in the SSD1306. If this is happening then your graphic data is probably not being transferred between your MCU and the SSD1306. This almost certainly means you have a problem in your porting layer.

Speckled Screen

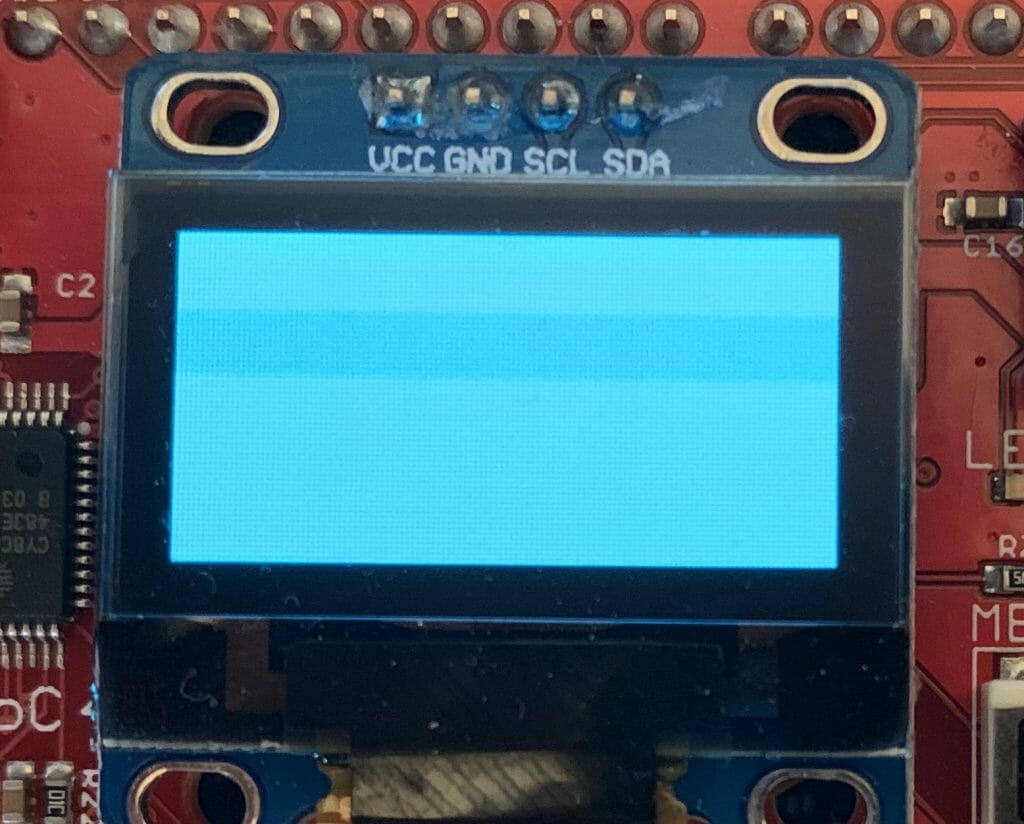

If your screen is solid white that probably means you turned the screen back on without resuming from the graphics ram. You did this:

OLED_DISPLAYALLONIGNORE, // 0xA5, //Set entire display on/off

instead of this:

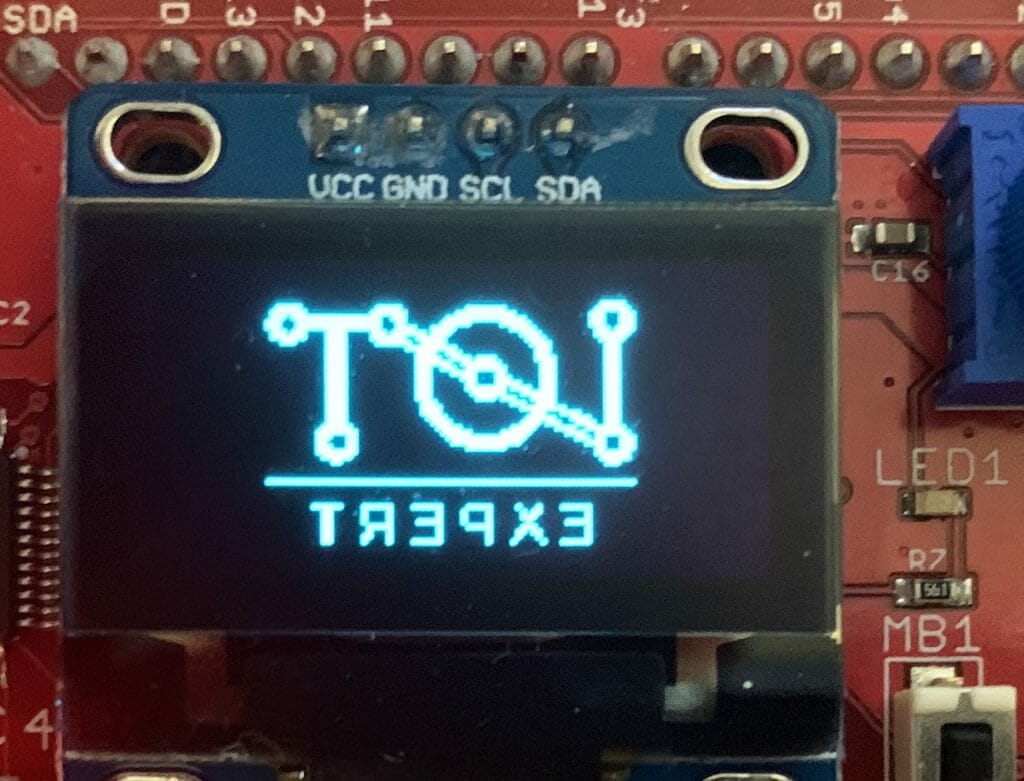

Screen Flipped in the X Direction

In the X-Direction the A0/A1 set the configuration of scanning. Try using A0–>A8 or the other way.

// X Direction Scanning #define OLED_SEGREMAPNORMAL 0xA0 #define OLED_SEGREMAPINV 0xA1

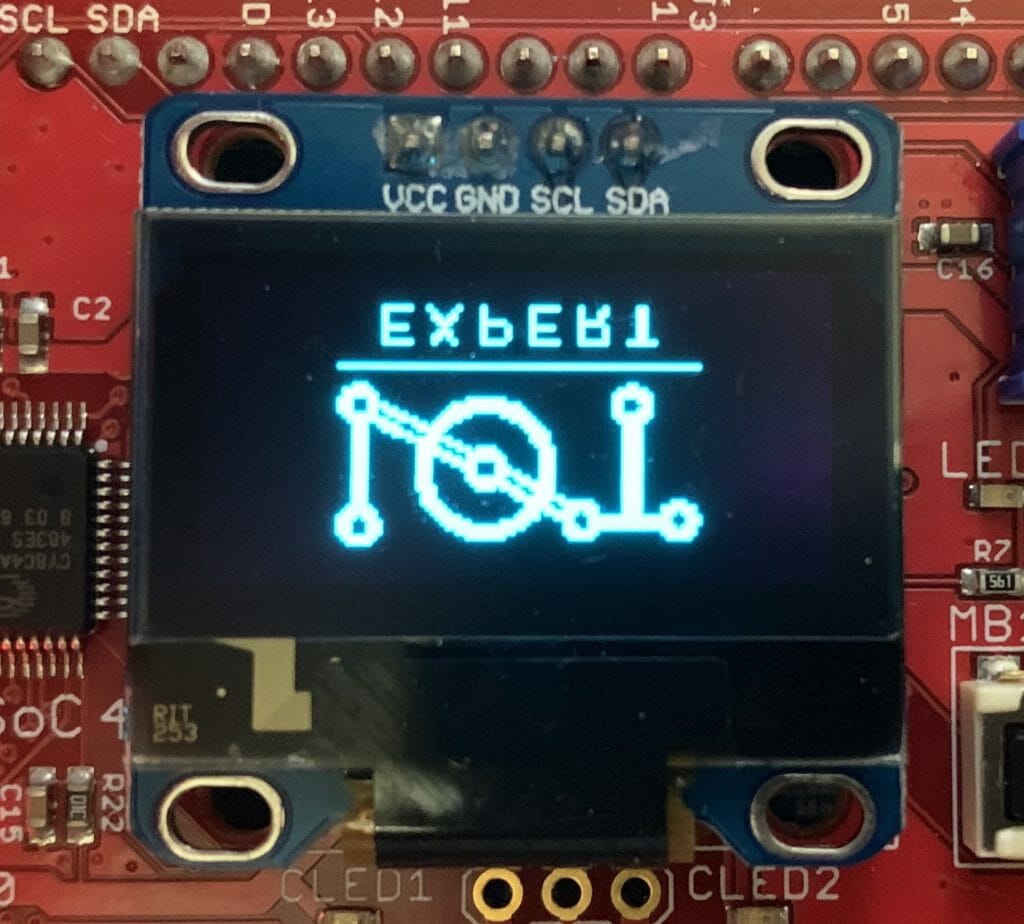

Screen Flipped in both Directions

If it is flipped in both X and Y direction then flip both of the direction registers.

// Y Direction #define OLED_SEGREMAPNORMAL 0xA0 #define OLED_SEGREMAPINV 0xA1 // X Direction #define OLED_COMSCANINC 0xC0 #define OLED_COMSCANDEC 0xC8

Screen is Inverted

If your screen is inverted then try A8–>A6

#define OLED_DISPLAYNORMAL 0xA6 #define OLED_DISPLAYINVERT 0xA7

Image is Partially off the Screen

If your image is off the screen the you probably have the wrong value for MULTIPLEX.

#define OLED_SETMULTIPLEX 0xA8

The parameter is supposed to be the number of lines on the screen -1. In my case the screen is 128×64 so my valued should be 63 aka 0x3F

OLED_SETMULTIPLEX, // 0xA8 Set multiplex ratio

0x3F, // Vertical Size - 1

Image is Wrapped on the Screen

// Double byte CMD image wrap ...probably should be 0 #define OLED_SETDISPLAYOFFSET 0xD3

The offset value allows the board designer to hook up the rows in a crazy fashion. My screen has the top row to the top row number.

OLED_SETDISPLAYOFFSET, // 0xD3 Set Display Offset

0x00, //

Black Screen

If you screen is totally dead…

Then the charge pump may be off

//////// Charge pump regulator

OLED_CHARGEPUMP, // 0x8D Set charge pump

0x14, // VCC generated by internal DC/DC circuit

or maybe the screen is off… try turning it on.

OLED_DISPLAYON, // 0xAF //Set display on

or maybe you haven’t displayed anything. The screen is off trying sending a screen invert

#define OLED_DISPLAYINVERT 0xA7

The Screen Has Gone Crazy

The register 0xDA SetComPins register will make some crazy results of it isn’t set correctly. For my 0.96″ inch screen it needs to be set to 0x12

// Double Byte Hardware com pins configuration #define OLED_SETCOMPINS 0xDA // legal values 0x02, 0x12, 0x022, 0x032

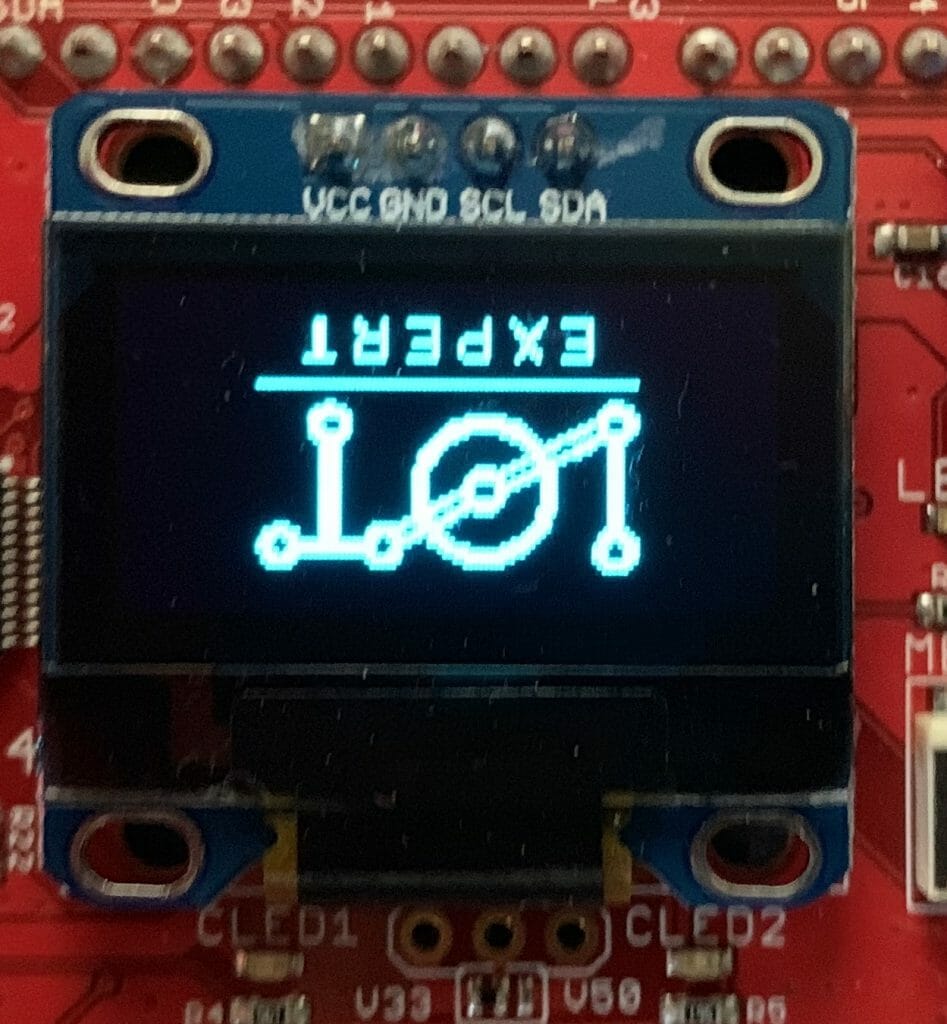

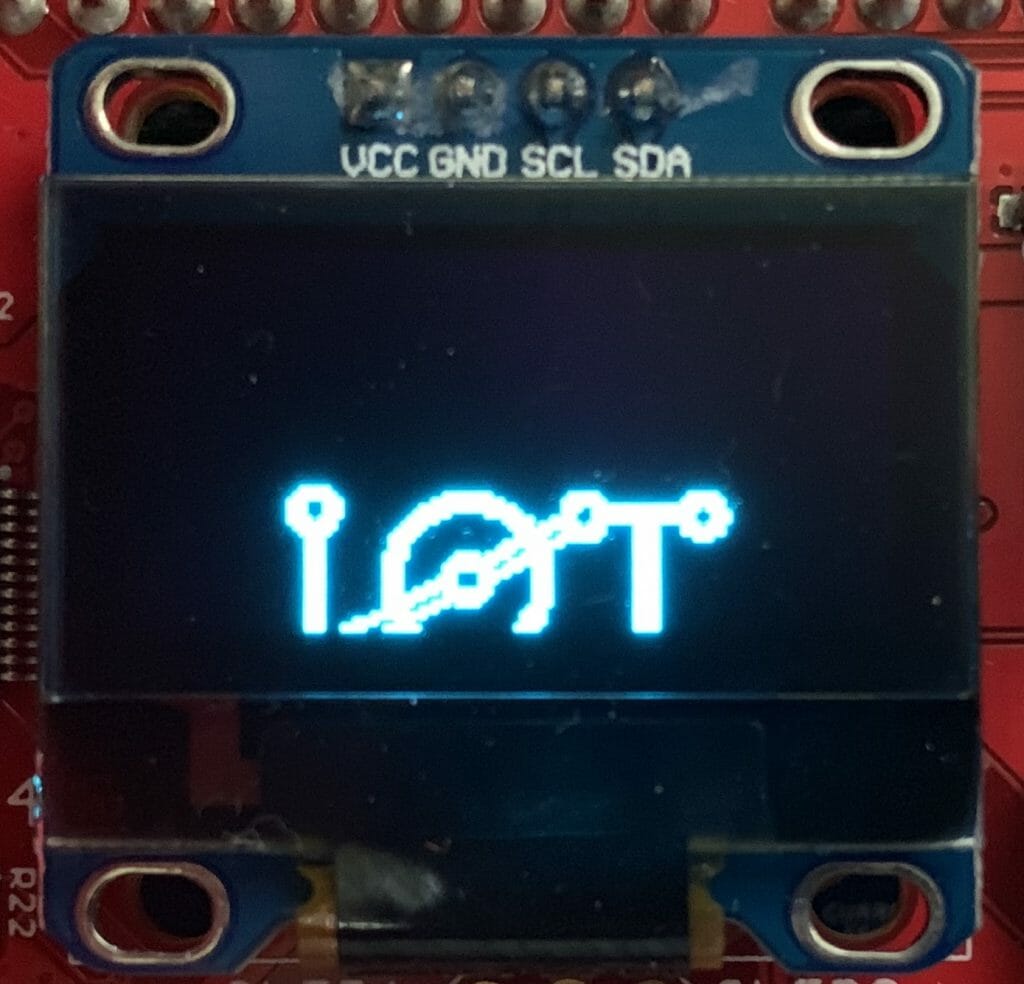

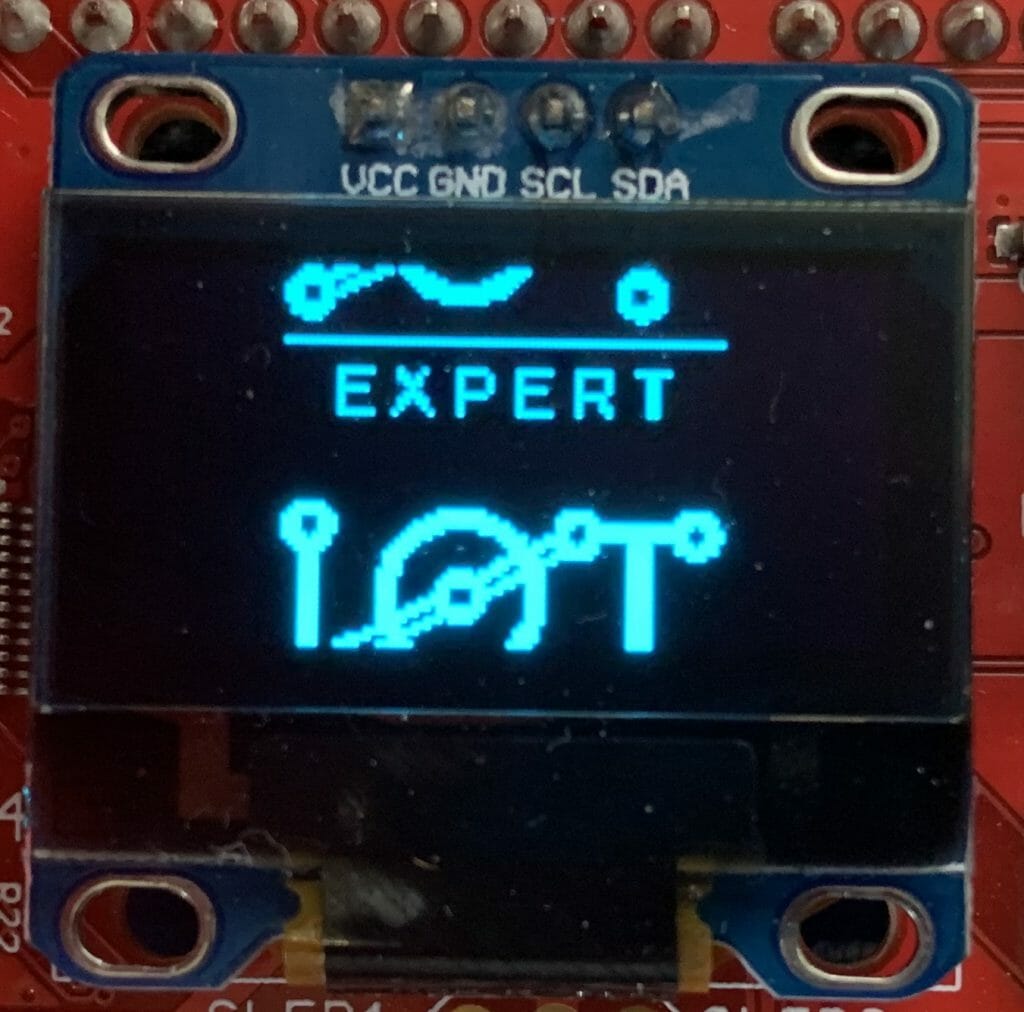

This is what happens with 0x02 [If you see the note below from Ivan, 0x02 is apparently for 128×32 and this screen is 128×64=0x12]

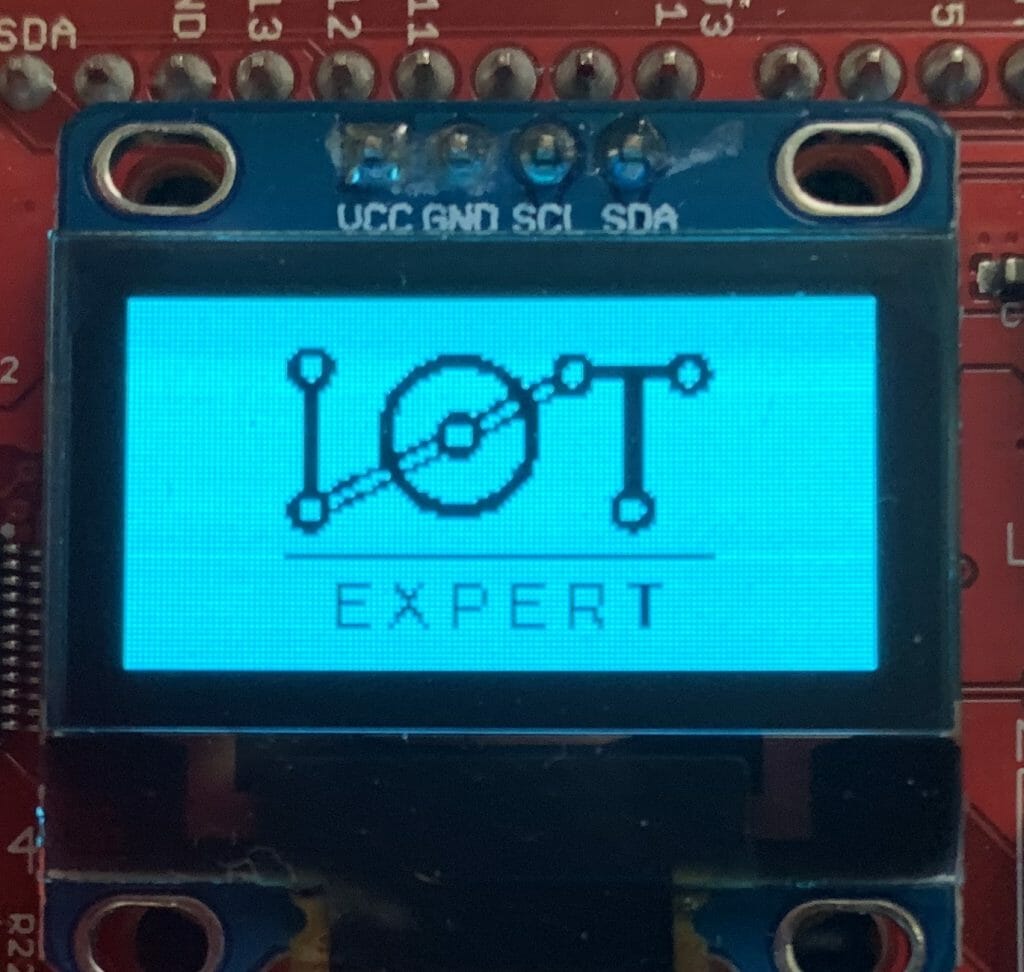

And 0x22

Finally 0x32

This was absolutely the craziest rabbit hole that I have ventured down. Nicholas has talked to me 10 times about doing this and he thinks I’m crazy. Oh well.

\

\

53 Comments

Hi Alan,

Thank you for a very handy and helpful guide. It obviously took a lot of effort, great work!

I managed to fix a speckled screen issue by adding a steady 3.3 V power supply.

Regards

Loot

Thanks

Nice job Alan! Many thanks for taking the time to write this up.

Thanks

Hi Alan,

Than you for this helpful tutorial.

Concerning the “crazy display” I would like to note that the OLED_SETCOMPINS, 0x02 combination is for the 128×32 pixels display (0.91″) and the OLED_SETCOMPINS, 0x12 combination is for the 128×64 pixels diplay (0.96″ what you own).

I don’t know about the role of the 5th bit (i. e. 0x22 and 0x32) however.

Nice catch

Hi Alan,

Some basic questions:

For the SSD1306 , does the Co bit have to be set when the command has a parameter that follows it like the Set Contrast Control command followed by the contrast setting? Likewise when the command is a single byte it should have the Co bit cleared?

Should a stop follow each command / command + parameter or not?

I don’t know… if you have figured it out by now Id like to update this article though.

I am currently writing a driver for the ssd1306 myself. I have noticed that Co can be low all the time. The datasheet is not very clear about the consequences. From the datasheet language I think a high Co bit means that no more control Bytes May come (only data). I am running an initialization sequence on my module using Co set low, with no control Bytes between the commands. I wish the datasheet were clearer about it, but this is my empirical evidence.

Oops, I got the Co bit backwards in my memory. I would delete my above comment, but the UI won’t let me.

I am struggling trying to get mine to respond. I must have tried >5 different driver code from different sources. By far, yours has the best explanations and flow of information. I really don’t know what else to try. I am powering the OLED module from the 3.3v on my dev board. I have the same oled module you used (I2C 4-pin module) – and the voltage on Vcc is ~3.2v. I am using two 2.2K pull-up resistors on the SCL & SDA. And I am tried this module with another sensor at the same I2C bus so I know the I2C works. I even tried the 100K & the 400K speeds – same the screen is dead!

Here is my init code (I followed your order):

void OLED_Init( void )

{

//////// Fundamental Commands

ssd1306_command( SSD1306_DISPLAY_OFF);

ssd1306_command( SSD1306_SET_CONTRAST_CONTROL );

ssd1306_command(0x7F);

ssd1306_command( SSD1306_NORMAL_DISPLAY );

//////// Scrolling Commands

ssd1306_command( SSD1306_DEACTIVATE_SCROLL );

//////// Addressing Commands

ssd1306_command( SSD1306_MEMORY_ADDR_MODE );

ssd1306_command(0x02); //??????Page

//////// Hardware Configuration Commands

ssd1306_command( SSD1306_SET_SEGMENT_REMAP);

ssd1306_command( SSD1306_SET_MULTIPLEX_RATIO );

ssd1306_command( 0x3F );

ssd1306_command( SSD1306_COM_SCAN_DIR_DEC );

ssd1306_command( SSD1306_SET_DISPLAY_OFFSET );

ssd1306_command(0x00);

ssd1306_command( SSD1306_SET_COM_PINS );

ssd1306_command( 0x12 );

//////// Timing and Driving Settings

ssd1306_command( SSD1306_SET_DISPLAY_CLOCK_DIV_RATIO);

ssd1306_command( 0x80);

ssd1306_command( SSD1306_SET_PRECHARGE_PERIOD );

ssd1306_command( 0x22 );

ssd1306_command( SSD1306_SET_VCOM_DESELECT );

ssd1306_command( 0x20 );

//////// Charge pump regulator

ssd1306_command( SSD1306_CHARGE_PUMP );

ssd1306_command(0x14);

// Turn the screen back on…

ssd1306_command( SSD1306_DISPLAY_ALL_ON);//SSD1306_DISPLAY_ALL_ON_RESUME );

ssd1306_command( SSD1306_DISPLAY_ON );

ssd1306_command( SSD1306_INVERT_DISPLAY ); // I added this out of despair just to see it turn on

}

static void ssd1306_command( uint8_t command )

{

I2C2Start();

I2C2Write(SSD1306_ADDR << 1);

I2C2Write(0x00);

I2C2Write(command);

I2C2Stop();

}

When you send an I2C Write do you get an ACK?

When you check the error codes what do you get?

Alan

Thanks Alan!

I did another round of testing and I finally got it to turn on using the setup sequence you provided. I don’t know what was the problem, It started working once I changed the I2C speed to 400K!

Now, I am trying to follow your example above to turn on a few bits and it doesn’t seem to work. Here is my code (and thank you again):

void OLED_Update2() {

int i;

command(0xAE); // display off

command(0x20); // memory address mode

command(0x00); // horizontal

command(0xA4); // display all on resume

command(0xAF); // display on

command(0x21); // set column address

command(0x00); // column start address

command(127); // column end address

command(0x22); // Set Page address

command(0x00); // page start address

command(7); // page end address

for (i = 0; i<16;i++)

{

data(0xAA);

}

}

double command(uint8_t command)

{

I2C2Start();

I2C2Write(SSD1306_ADDR << 1);

if (!I2C2__SlaveAcknowledged()) return 0.1;

I2C2Write(0x00);

if (!I2C2__SlaveAcknowledged()) return 0.2;

I2C2Write(command);

if (!I2C2__SlaveAcknowledged()) return 0.3;

I2C2Stop();

return 0;

}

void data(uint8_t value) {

I2C2Start();

I2C2Write(SSD1306_ADDR << 1);

I2C2Write(0x40);

I2C2Write(value);

I2C2Stop();

}

Thats good…

I’m glad you sorted it out.

Im guessing you where having some trouble with the I2C startup.

Alan

Hi, Alan

This is the great article detailed about SSD1306 display

I worked on STM32 with SSD1306 (128*32) display

I’ve got the “speckled screen” issue.

I’ve tried different initial procedures from github and different display, but I always get speckle screen..

There are two power sources on my board

1. VDD: 3.3V for logic circuit

2. Vcc: 7.5V for display

============================================

Do you know how to examine my setup (HW and SW) to clarify this issue?

and I’m confused about “initialize procedure” should be before power up or later power up of my MCU?

and from SSD1306 spec, there’s a figure about Power ON sequence, do i have to control RES# of display?

Well… that isn’t exactly the MCU that i was targeting 🙂 but I’m glad you got it working!

Hi Alan, thank you for your guide.

My problem is I am able to make it work with page addressing but not with horizontal or vertical addresing.

I used my code, Adafruit library, your examples… nothing. I’m using SPI and I used I2C.

Any clue?

I don’t know about the Adafruit library… so I am not sure what to say. Im sorry.

how does this produce 12 columns char horizontalExample[]= {

0xAE,

0x20, /// address mode

0x00, // Horizontal

0xA4,

0xAF,

0x22, //Set page address range

0,

7,

0x21, // column start and end address

0,

127,

};

I2C_WriteCmdStream(horizontalExample, sizeof(horizontalExample));

// Write twelve bytes onto screen with 0b10101010

for(int i=0;i<12;i++)

I2C_WriteData(0xAA);

the picture you have only shows only 4 rows.

0xAA = 10101010 … so the 4 rows you see are really 8… 1 row solid, 1 row empty, ….

Alan

Hi Alan,

As a first point, thank you for your clear data about the SSD1306 chip.

At this point, the change pump of the 128×64 0.96″ device I’m running does not start: the charge pump voltage does not increase above 3.3V.

The voltage measured across the Iref resistor is zero (R = 914 k)

As a consequence, the display is 100% black.

The chip returns the right ACK during the I2C transaction (270kHz clock). The microprocessor is a NXP mc9S08AC60, code in C

Could you give me some directions to clear this issue? Thank a lot !

Michael

Wow…. that is crazy.

Just out of curiosity did you try a different display? I have noticed quite a bit of variation in the quality of these displays. I designed one into a board that I made a few hundred off … and there were “some” that were dead.

Short of that? Im not sure… I can’t think of anything right off hand… but Ill think about it.

Alan

Hi Alan,

Well, my previous answer went somewhere in the air …

So far, the display is now active:

1 – the charge pump reservoir capacitor was very leaky, not to say short … A new capacitor cleared this issue.

2 – the output regulator voltage yields a 800mV ripple on top of the 3.3V: based on the standards silicon chip , this is probably a too large ripple. An extra 100uF in parallel with the existing part reduced the ripple to less than 100mV

Right now, I’ve difficulties to force the display to white on black (like your images) and to display a single pixel or a single line: probably more hours to spent on this module. The i2c com is fine with a proven ACK for each data exchange, waveform are OK … but poor display !!

Thank you so much for your support

Michael

Hi Alan,

Thank’s for your comments: a really strange situation.

In the mean time, I’ve solved the charge pump issue: change the 910k resistor to 410 k(available from stock ..) to cope with the SSD1306 data sheet, and replace the 7V leaky (almost short..)filter capacitor by a new fresh 10uf ceramic.

On the other hand, a 500mV voltage drop was visible on the 3.3V voltage : I add a 10uF cap in parallel with the existing the filter capacitor= the voltage drop is reduced to 87 mV. Not perfect, but (normally) within the chip specifications.

The display is no longer 100% black, but yields a “nice” Speckled image like the one you give on your technical stuff. I presume this is a software issue: will work on this point right away ! As a matter of fact, the SSD1306 data is not really high end in term of details… but that’s life !

I’ll be back to you with the results !!

Michael

Wow… that is quite a bit of work for a $1.96 display.

Hi Alan, I’m actually trying to use this display for a digital design project using a microncontroller similar to the mbed. I’m not able to fully figure out how to get the display to show anything. I’ve figured out for the most part how to send the data and used some of the code that you showed, but I think I might be missing some commands. Is there any way you’d be willing to post the full code for some of the things that you showed, such as the vertical example and horizontal example? Any help would be appreciated, thanks!

Apparently I did the work using the MBED OS.

The git repo is:

git@github.com:iotexpert/SSD1306_MBEDOS.git

Hi Alan, I’m having a lot of issues with my display. I’m able to get it to turn on and show what it’s supposed to, but the display doesn’t clear what is on there. So even if I load a new image on there, the display still shows what was previously on there in addition to the new thing, and I can’t figure out what I’m doing wrong. I have two 10k pullup resistors connected to SDA and SCl. Maybe it needs to be higher? Here is my code that I’m using.

#include “mbed.h”

#define DISPLAY_RESET 0xD0

#define SSD1306_LCDWIDTH 128

#define SSD1306_LCDHEIGHT 64

#define SSD1306_SETCONTRAST 0x81

#define SSD1306_DISPLAYALLON_RESUME 0xA4

#define SSD1306_DISPLAYALLON 0xA5

#define SSD1306_NORMALDISPLAY 0xA6

#define SSD1306_INVERTDISPLAY 0xA7

#define SSD1306_DISPLAYOFF 0xAE

#define SSD1306_DISPLAYON 0xAF

#define SSD1306_SETDISPLAYOFFSET 0xD3

#define SSD1306_SETCOMPINS 0xDA

#define SSD1306_SETVCOMDETECT 0xDB

#define SSD1306_SETDISPLAYCLOCKDIV 0xD5

#define SSD1306_SETPRECHARGE 0xD9

#define SSD1306_SETMULTIPLEX 0xA8

#define SSD1306_SETLOWCOLUMN 0x00

#define SSD1306_SETHIGHCOLUMN 0x10

#define SSD1306_SETSTARTLINE 0x40

#define SSD1306_MEMORYMODE 0x20

#define SSD1306_MEMORYMODE_PAGE 0x02

#define SSD1306_COLUMNADDR 0x21

#define SSD1306_PAGEADDR 0x22

#define SSD1306_COMSCANINC 0xC0

#define SSD1306_COMSCANDEC 0xC8

#define SSD1306_SEGREMAP 0xA0

#define SSD1306_CHARGEPUMP 0x8D

#define SSD1306_CHARGEPUMP_ON 0x14

#define SSD1306_EXTERNALVCC 0x1

#define SSD1306_SWITCHCAPVCC 0x2

I2C i2c(p28, p27);

char _i2c_address;

char display_buffer[1024];

void ssd1306_command(char c){

char control = 0x00;

i2c.start();

i2c.write(_i2c_address);

i2c.write(control);

i2c.write(c);

i2c.stop();

}

void ssd1306_data(char c){

i2c.start();

i2c.write(_i2c_address);

i2c.write(0x40);

i2c.write(c);

i2c.stop();

}

void setColAddress()

{

ssd1306_command(SSD1306_COLUMNADDR); // 0x21 COMMAND

ssd1306_command(0); // Column start address

ssd1306_command(SSD1306_LCDWIDTH-1); // Column end address

}

void setPageAddress()

{

ssd1306_command(SSD1306_PAGEADDR); // 0x22 COMMAND

ssd1306_command(0); // Start Page address

ssd1306_command((SSD1306_LCDHEIGHT/8)-1);// End Page address

}

void InitializeDisplay()

{

// Init sequence for 128×64 OLED module

ssd1306_command(SSD1306_DISPLAYOFF); // 0xAE

ssd1306_command(SSD1306_SETDISPLAYCLOCKDIV); // 0xD5

ssd1306_command(0x80); // the suggested ratio 0x80

ssd1306_command(SSD1306_SETMULTIPLEX); // 0xA8

ssd1306_command(0x3F);

ssd1306_command(SSD1306_SETDISPLAYOFFSET); // 0xD3

ssd1306_command(0x0); // no offset

ssd1306_command(SSD1306_SETSTARTLINE);// | 0x0); // line #0

ssd1306_command(SSD1306_CHARGEPUMP); // 0x8D

ssd1306_command(0x14); // using internal VCC

ssd1306_command(SSD1306_MEMORYMODE); // 0x20

ssd1306_command(SSD1306_MEMORYMODE_PAGE);

ssd1306_command(0x00); // 0x00 horizontal addressing

ssd1306_command(SSD1306_SEGREMAP | 0x1); // rotate screen 180

ssd1306_command(SSD1306_COMSCANDEC); // rotate screen 180

ssd1306_command(SSD1306_SETCOMPINS); // 0xDA

ssd1306_command(0x12);

ssd1306_command(SSD1306_SETCONTRAST); // 0x81

ssd1306_command(0xCF);

ssd1306_command(SSD1306_SETPRECHARGE); // 0xd9

ssd1306_command(0xF1);

ssd1306_command(SSD1306_SETVCOMDETECT); // 0xDB

ssd1306_command(0x40);

ssd1306_command(SSD1306_DISPLAYALLON_RESUME); // 0xA4

ssd1306_command(SSD1306_NORMALDISPLAY); // 0xA6

ssd1306_command(SSD1306_DISPLAYON); //switch on OLED

}

void horizontalExample()

{

ssd1306_command(0xAE);

ssd1306_command(0x20);

ssd1306_command(0x01);

ssd1306_command(0xA4);

ssd1306_command(0xAF);

ssd1306_command(0x22);

ssd1306_command(0);

ssd1306_command(0x7);

ssd1306_command(0x21);

ssd1306_command(0);

ssd1306_command(127);

}

int main() {

// fill buffer with something for test

//memset( display_buffer, 0X02, 1000); // tried other values

_i2c_address = 0x78;

InitializeDisplay();

horizontalExample();

for (int i = 0; i < 12; i++)

{

ssd1306_data(0xAA);

}

while(1)

{

wait_ms(10); // keyboard code here

// if(DigitalIn(LED1) == 0){DigitalOut(LED1,1);}

// else{DigitalOut(LED1,0);}

}

}

I dont think that your problem has anything to do with the I2C resistors if the display is displaying…

I think that you problem is that you need to clear the frame buffer inside of the SSD (by writing 0’s)…

Alan

I think the purpose of “all on, ignore VRAM” is to just quickly test for dead pixels.

One thing I found is that the protocol for the 128×32 displays seems very wasteful. You still send 128×64 bits and every second bit gets thrown out! Is there some setting I overlooked to not have to waste 50% of your bandwidth?

#1… thanks for the comment on the VRAM.

#2 I don’t think that my implementation does what you describe by sending 2x pixels… what am I missing?

Thanks,

Alan

Thank you very much from Bedfordshire UK,

for this wonderful supplement to the SSD1306 data sheet.

williamm8629.

You are welcome

Hi All:

I have an OLED display that works with I2C (STM32F303). It is frozen when I got a spark. I isolated the circuit of the Microcontroller from the H.V circuit by using an optocoupler

Is there any Hardware or Software addresses this issue?

Thanks

A spark… wow.. did you get magic smoke after that? I suppose that Im not sure what your question is with respect to Hardware. For sure you answer of the optocoupler should work… I have never ever blown one of these things up. As far as software goes? I dont think that there is anything that you can do about a problem like the one you describe.

Sorry I couldn’t be of more help. Good luck

Alan

Just wanted to thank you for all the detailed work you put into this post. I’m only just starting to play around with an Arduino and had picked up on of these cheap displays to try out but I wanted to understand how it worked as opposed to just loading up a sample and seeing some images dance around the screen. This post was really helpful.

Thanks,

Dan

You are very welcome.

Alan

Alan – thank you for the guide. I’m going down my own rabbit hole with an SSD1322 and this is super helpful to get inside the minds of the Solomon Systech folks. You are a rock star, thank you for taking the time to put this together. Oh, I found a reason for the “but why?” on ignoring GDDRAM. It’s useful for the initial “does this thing even want to talk to me” when starting a driver journey. It worked well for me when stepping through the first iterations of my code Other than that, I can’t think of another good reason other than a cheap way to strobe the screen in an alert condition.

Thanks for the nice words.

The answer to the question of why is that it is apparently used in a manufacturing test. (someone else either commented or emailed me… I forget)

Alan

Great article Alan! Many thanks. You pose a question in the beginning why you would want all pixels ON. Well, maybe (automated) QA wants to do a dead pixel test before approving the device? Just a thought.

Cheers, Peter

Yes. This is the right answer I think.

Alan

Hi Alan

I experienced a problem with a ‘bicolor’ (blue & yellow) version of the SSD1306 : there is a dummy line between the yellow section and the blue one. This is clearly visible when you draw a diagonal line on the whole screen. This does not happens (luckily…) on monochrome versions. Is this (due to filter positioning constraints, I presume) common to all bicolor versions of this display ?

Many thanks, specially for the Set Charge Pump command description.

Jean

I have no idea about the blue/yellow one… I haven’t ever seen one other than in the google images.

If you figure it out send me an email and Ill update the article.

Thanks for the nice words.

Alan

Hello Alan. Thanks for the article. The SSD1306 datasheet is terrible and this actually helped! I am working with STM32 in cubeIDE so the standard “just use the adafruit/ other canned library” isn’t an option for me. Plus, I like to make my own libraries!

Anyway I got the screen working, but I think you may have the values for multiple/single data transfers (0xC0, 0x40) backwards. I was chasing this problem for a long time until I randomly flipped which one I was using and all of the sudden it was working! if I try to send a whole buffer with 0xC0, it only sends the first column (sometimes it is also on the second page… weird), but if I send the same buffer with 0x40, it works fine!

Referencing the terrible datasheet 8.1.5.2:

5) After the transmission of the slave address, either the control byte or the data byte may be sent across

the SDA. A control byte mainly consists of Co and D/C# bits following by six “0” ‘s.

a. If the Co bit is set as logic “0”, the transmission of the following information will contain

data bytes only.

b. The D/C# bit determines the next data byte is acted as a command or a data. If the D/C# bit is

set to logic “0”, it defines the following data byte as a command. If the D/C# bit is set to

logic “1”, it defines the following data byte as a data which will be stored at the GDDRAM.

The GDDRAM column address pointer will be increased by one automatically after each

data write.

Under “a” it doesn’t mention anything about setting the co bit to 1 which might shed some light on the issue, but it does mention that setting is as 0 “the transmission of the following information will contain

data bytes only.” which is ambiguous, but I interpret as meaning there will be a stream, not individual messages. This does make sense with 0xC0 vs. 0x40 though.

Not sure on multiple/single commands as I only send them one at a time in my init function. I have noticed others in these comments with trouble initializing, so here is my init code that works for me (STM32L432 nucleo board / cubeIDE) NOTE this is still “sketched code” as I am still actively working on it and haven’t done any cleanup yet…

ssd1306_WriteCommand(SSD1306_SCREEN_OFF); // screen off

ssd1306_WriteCommand(SSD1306_CMD_MEMMD); // mem mode:

ssd1306_WriteCommand(SSD1306_CMD_MD_HRZ); // horizontal

ssd1306_WriteCommand(SSD1306_CMD_COLRNG); // column range:

ssd1306_WriteCommand(0);

ssd1306_WriteCommand(127);

ssd1306_WriteCommand(SSD1306_CMD_PGERNG); // page address range:

ssd1306_WriteCommand(0);

ssd1306_WriteCommand(7);

ssd1306_WriteCommand(SSD1306_CMD_VFLIP_OFF);// flip vertically

ssd1306_WriteCommand(SSD1306_CMD_HFLIP_OFF);// flip horizontally

ssd1306_WriteCommand(SSD1306_CMD_USE_BUFF);

ssd1306_WriteCommand(SSD1306_SCREEN_ON); // screen on

And my functions for writing data and commands are as follows (using HAL I2c)

/**

* Send a byte to the command register (0x00)

* @param command

*/

static void ssd1306_WriteCommand(uint8_t command)

{

HAL_I2C_Mem_Write(&hi2c1, I2C_ADDR, SSD1306_REG_1CMD, 1, &command, 1, 10);

}

/**

* Send a byte to the data register (0xC0)

* @param data

*/

static void ssd1306_WriteData(uint8_t data)

{

HAL_I2C_Mem_Write(&hi2c1, I2C_ADDR, SSD1306_REG_1DAT, 1, &data, 1, 10);

}

/**

* Send buffer to the data register (0x40)

* @param data

*/

static void ssd1306_WriteMData(const uint8_t *data, uint16_t size)

{

HAL_I2C_Mem_Write(&hi2c1, I2C_ADDR, SSD1306_REG_MDAT, 1, (uint8_t*)data, size, 100);

}

Hope this helps someone!

Crazy eh….

Thanks.

Alan

Excellent article, apart from one thing. COMPINS is being set to 0x12. The manual says that it takes notice of bits 4 and 5. That means it should never be anything other than 0x00, 0x10, 0x20 or 0x30. I have no idea why people are universally saying about it being 0x12, and that ‘legal’ values are 0x02, 0x12, 0x22 and 0x32. Is there a document somewhere that I can’t see?

I’ve set it to 0x10 and it’s fine.

I don’t know… but I bet you are right.

The V1.1 of the datasheet shows bit1 set for the data word of COMPINS even though only bits 4 and 5 are talked about (page 31). This is a very confusing datasheet! I seem to get the same results with or without these bits set so I think you are right in that they don’t matter.

Confusing for sure…. hours and hours I spent looking and testing.

My guess is that there are also silicon revisions which might not all be quite the same as well

Hi.

My screen in speckled 30% of the time, rest of the time it works perfect. According to your post you say:

“If this is happening then your graphic data is probably not being transferred between your MCU and the SSD1306. This almost certainly means you have a problem in your porting layer.”

Can you be a bit more specific, i don’t really understand what you mean by porting layer.

Best Regards

The part of your firmware that sends and receives bytes from the display. Im guessing you have a timing problem in the “hal”

Hi Alan,

outstating and vy helpful website. Thanks for going all the length.

One point if I may as to the command-Byte: different from your WebSite I found:

int const commands = 0x00;

int const onecommand = 0x80;

int const data = 0x40;

int const onedata = 0xC0;

to be working.

be well, Thomas

Hello Alan. Thanks for the article.

0x40: multiple data

0xC0: one data byte

i test it.it its correct