Summary

A discussion of the algorithms to calculate water volume in Beer Smith 3.0 including a spreadsheet showing the calculations. What does this have to do with IoT? Nothing.

Story

I am a new brewer. I started at the beginning of COVID in March 2020. At this point I have only done 26 batches so I am a long way from expert. For sure there is no danger of BrewExpert.com from me any time soon. But, I am also an engineer so I like to “know” (and if there are any IoT Expert people still reading, you will already know that)

I have been struggling to understand how much strike and sparge water to use during the making process. I own and use a Grainfather, so I have been using their software, but honestly Im not a huge fan. Nathan at BrewerDude, my local home brew store, told me that using Beer Smith was the best way to improve my results. And, as you know figuring things out is more than half the fun for me. Game on.

Beer Smith 3.0 is a interesting piece of software written by Brad Smith that was made to design and help you implement beer recipes. The software was clearly built with years of “experience” in making beer and is also clearly a reflection of his workflow. The tool is seems to have a substantial amount of empirical knowledge built into the tool – Ohm’s laws for beer?

Now to the problem. I started trying to reconcile the water volume information coming out of Beer Smith with what was coming out of the Grainfather software. The numbers didn’t really add up and there were a bunch of things which I didn’t really know. Google here we come. Turns out there are a boatload hits that are some variant of “how do I match what the Grainfather and BeerSmith think for water volumes”. I am sure that there is a beautiful document in the Beer Smith documentation library which I haven’t found which explains the answer to the question of how the water volumes are calculated in Beer Smith, but I couldn’t find it.

So I decided to reverse engineer the calculations, which I mostly have done (with a few issues). They are all in a spreadsheet which you can download from the IoT Expert Github respository which you can find at https://github.com/iotexpert/Beer.git That repository contains a spreadsheet called “beer-smith-water.xlsx” which has my version of the formulas which seem to match BeerSmith 3.1.08

I am quite sure that this water volume issue is obvious to everyone, except me. But, as I said, I’m only 26 batches into this brewing adventure. For the rest of this article I will focus only on the parameters that impact water volume in Beer Smith.

First I will walk through the screens that impact water then I will show the “Vols” tab and my spreadsheet which mimics the calculations.

Getting Started

I will use the recipe “Abbey of the Blonds” from BrewerDude and my setup which is a Grainfather G30 and a Grainfather Conical Fermenter. Here is a picture of the front cover of the book that came with the recipe. Notice my handwritten notes that are the strike and sparge water… in both metric and imperial… and my note that the water values that I used to get a good result.

Before you can really look at the water volume numbers you need to do several things:

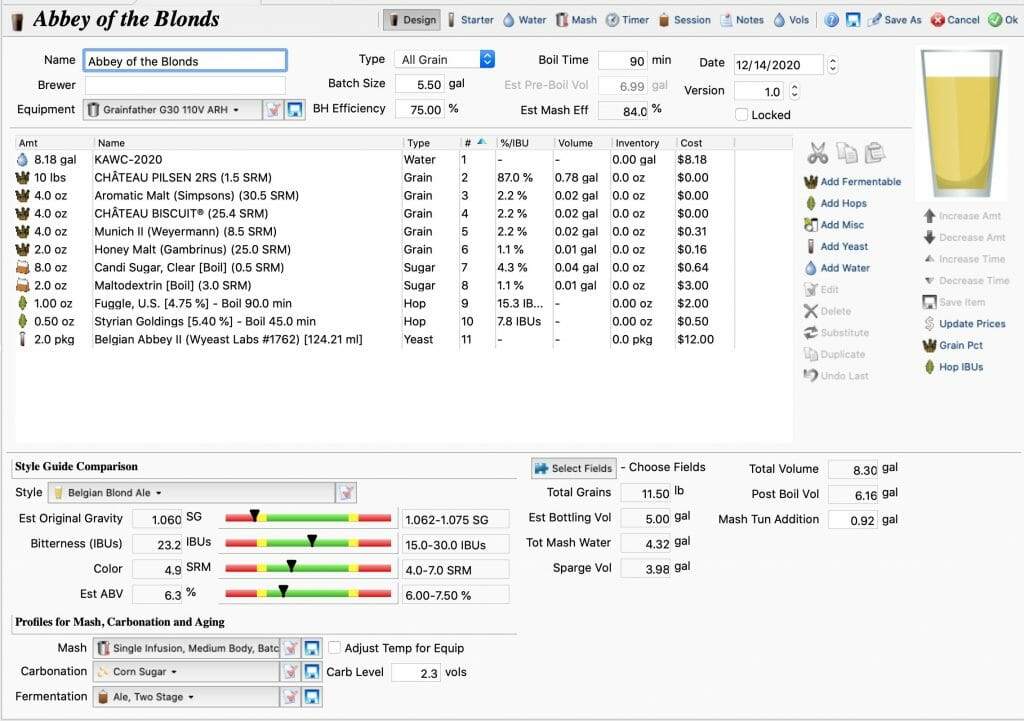

- Enter the recipe (which I copied from the nice document that came from BrewerDude along with the kit)

- Add your equipment (in the picture you can see that I added Grainfather G30 110V ARH). “ARH” are my initials and is my copy of the default configuration.

- Add your mash profile (in the picture you can see that I picked Single Infusion Medium Body, Batch Sparge)

- Set the boil time to 90 minutes (which over-rides the default of this equipment of 60 minutes)

- Notice the Batch Size of 5.5 gallons (which was copied from the equipment profile)

In the picture you can see that I changed the fields in the middle right to display the three water volume numbers that I am interested in, specifically:

- Tot Mash Water

- Sparge Water

- Total Volume

I do not believe that BH Efficiency impacts the water volume calculations.

Batch Size & A GUI Comment

The starting value for Batch Size is copied from Equipment Setup configuration. This number was intensely confusing to me for a good while until I got it sorted out that this is the total volume of cold wort going into the fermenter after the mash and boil. One thing that you should watch for is that this value is linked onto multiple menus/screens and a change in one place will effectively change it multiple places. When you change this value it appears to propagate throughout your recipe but it does not change the original source equipment profile.

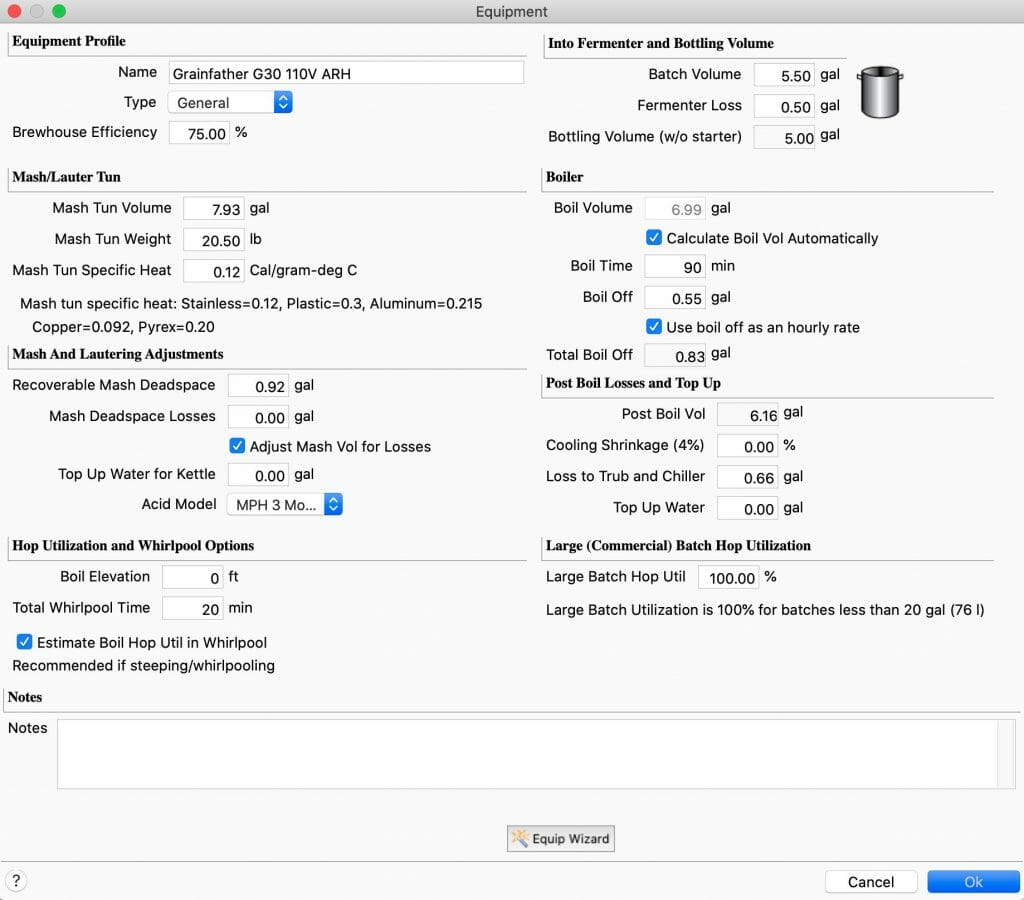

Equipment Setup

As I stated above, when you create the recipe you effectively COPY the equipment profile into your recipe. In other words the values in this tab become the default values for your recipe when you configure this equipment profile to be used for your recipe.

In the equipment profile the following values impact water:

- Batch Volume – How much wort you want to go into the fermenter

- Fermenter Loss – Dead space at bottom of the fermenter i.e. below the line where you bottle from

- Mash Tun Volume – Used as a check to make sure you don’t overflow during the mash. This doesn’t change the calculations, just a warning.

Mash Tun Weight– No impact on water? (pretty sure)Mash Tun Specific Heat– No impact on water? (pretty sure)- Boil Time – The default length of time to boil. This is copied into your reciepe. This parameter is used in the boil off calculation

- Boil Off – The input variable to the total boil off calculation

- Use boil as an hourly rate (if you click this boil off will vary with the boil time)

- Total Boil Off: Calculated boil off = Batch Size * boil time / 60 * Boil Off

- Recoverable Mash Deadspace – volume of water below the false bottom which WILL be part of the final wort

- Mash Deadspace Losses – the volume of water below the false bottom which willl be LOST and not part of the final wort

- Top Up Water for Kettle: How much water you add pre-boil

- Post Boil Vol: This is a calculated estimate based on the input parameters (more details later)

- Cooling Shrinkage: how much volume you loose as the wort cools

- Loss to Trub and Chiller – what it says

- Top Up Water – How much water you add into the fermenter

You will find that most of these values are copied onto the “Vols” screen later on.

Mash Profile

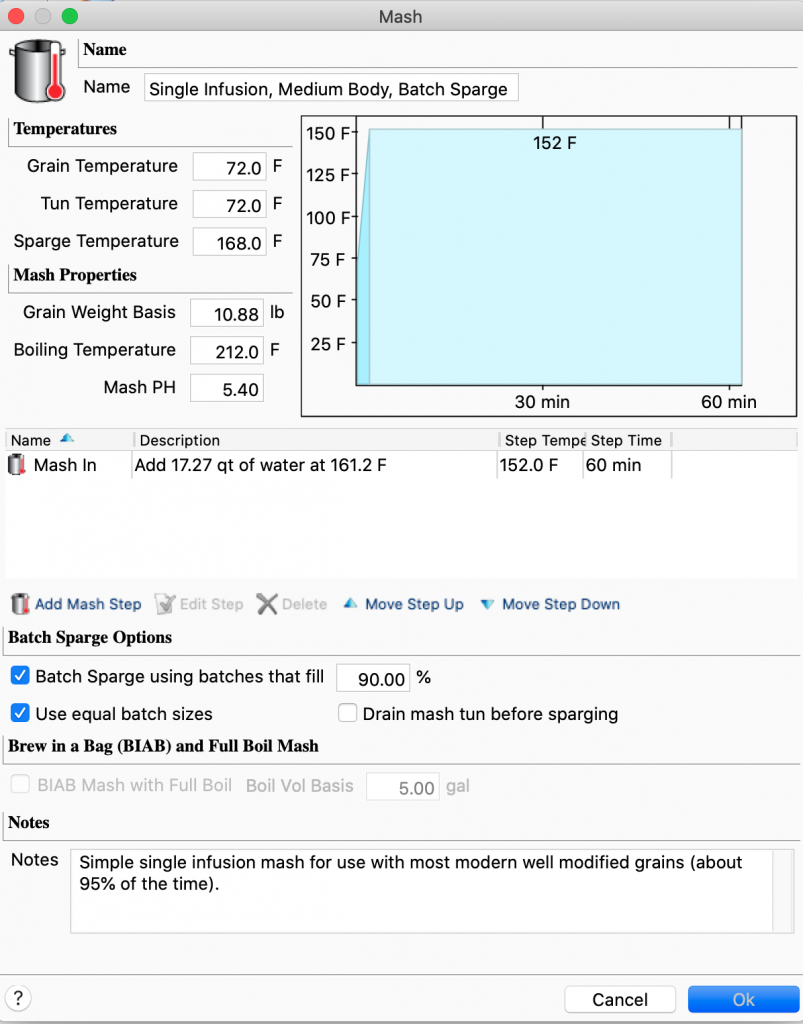

When you choose the mash profile it is the major input to the strike water calculations.

On the Mash screen the parameters:

- Grain Weight Basis – used for the calculation of strike water (derived from your inputs on the recipe)

- Mash In – will take you to the next screen where the strike water is calculated

I was lost trying to figure out where the strike water came from for quite a while until I realized that you could change the values on the “Mash In” step screen. To do this click on it and press “Edit Step” (where the water volume action happens). Really what is happening here is that you can create multiple steps in your mash process. Each step can/will impact the water used by that step. When you configure your reciepe to use a mash profile, you are essentially copying those steps into your recipe and they drive the values for strike water in your recipe.

As I work to write this article I notice for the first time “Batch Sparge using batches that fill 90%” but I have no idea what that impacts.

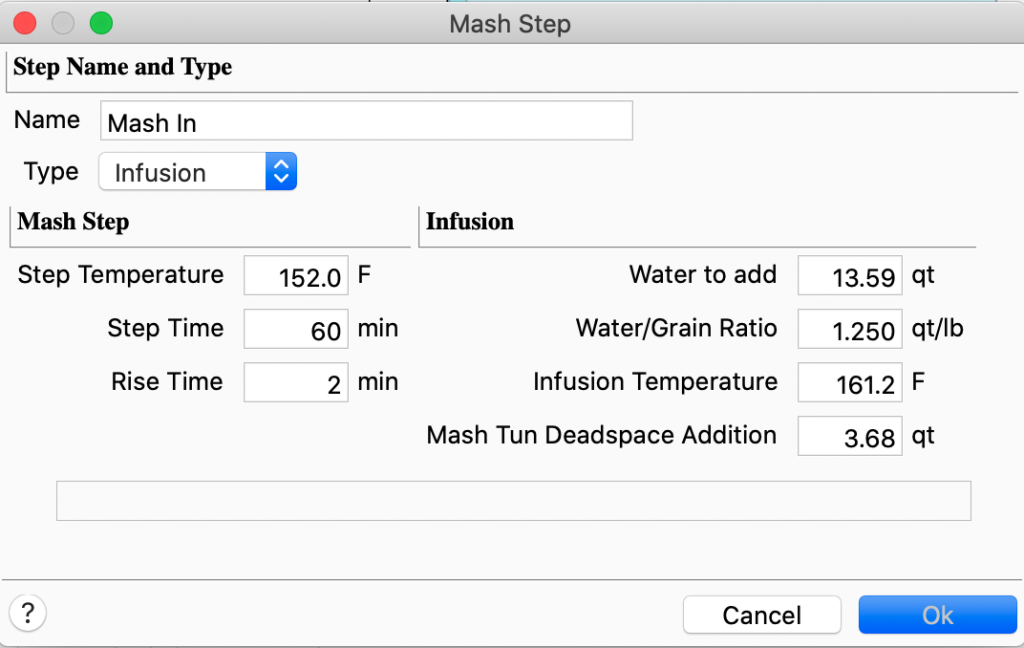

The Mash Step screen calculates the mash water for this step. The key metric is the Water/Grain Ratio which is used to calculate the “Water to add”. Where did the 1.250 qt/lb come from? I suspect that this is empirical. Notice that the water to add does NOT include the Mash Tun Deadspace Addition. This number was copied from the Equipment profile (which recall was 0.92 gallon = 3.68qt). Im sure that there was a good reason to add a place to enter this value here, but damn if I can figure it out. I’m also sure there was some good reason to change units, but Im also not sure why, but probably convenience.

The Advanced Options

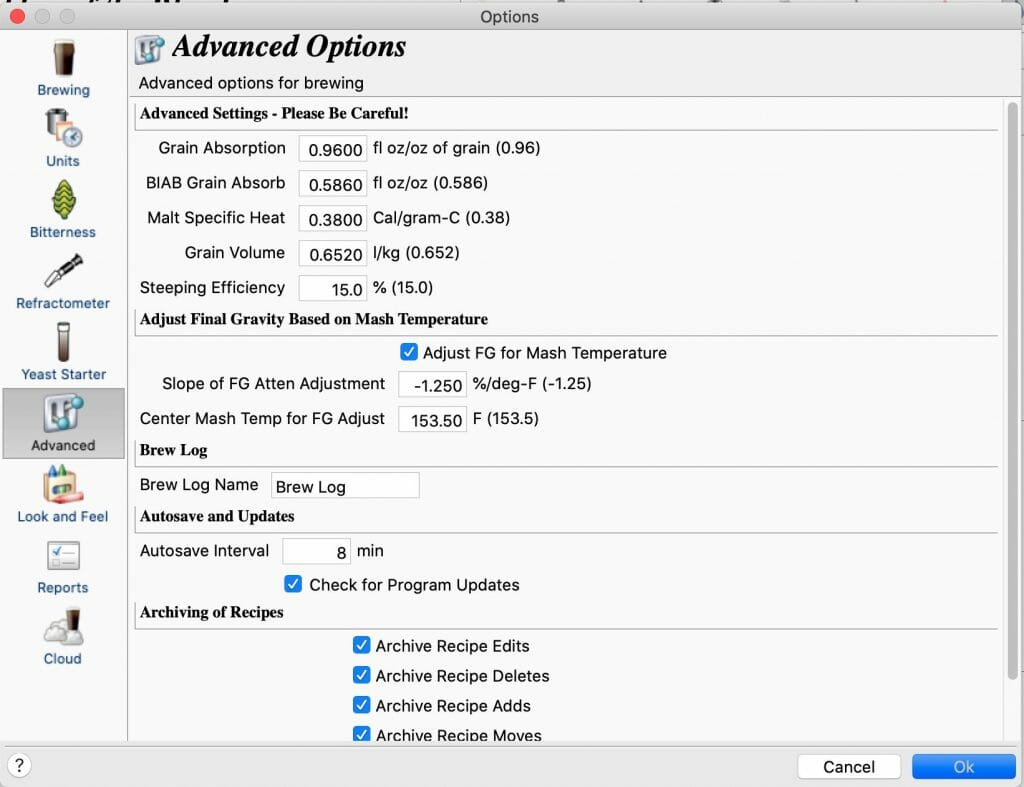

The advanced options screen (which can be accessed from the preferences button) has two numbers which are relevant to the water calculations

- Grain Absorption (how much water is absorbed by the grain) = 0.96 Fluid Oz per Oz of Grain

- Grain Volume (how much physical space is taken by the wet grain) = 0.6520 l/kg

Im quite sure that both of these numbers were arrived at empirically. These numbers are used in the upcoming “Vols” calculations.

The “Vols” Tab

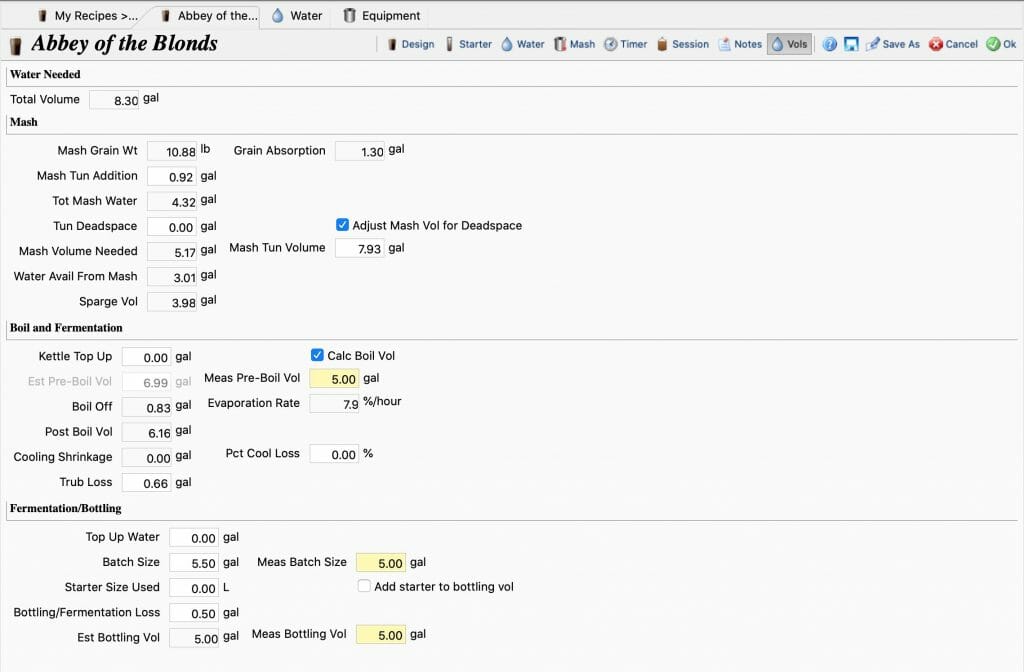

This tab is where the action happens. You can see and edit most of what you might want from a water volume point of view. This screen is broken up into four sections which I will walk through one by one.

- Water Needed

- Mash

- Boil and Fermentation

- Fermentation/Bottling

The first thing you should know on the “Vols” tab is that the Total Volume = Tot Mash Water + Sparge Vol and is calculated for you.

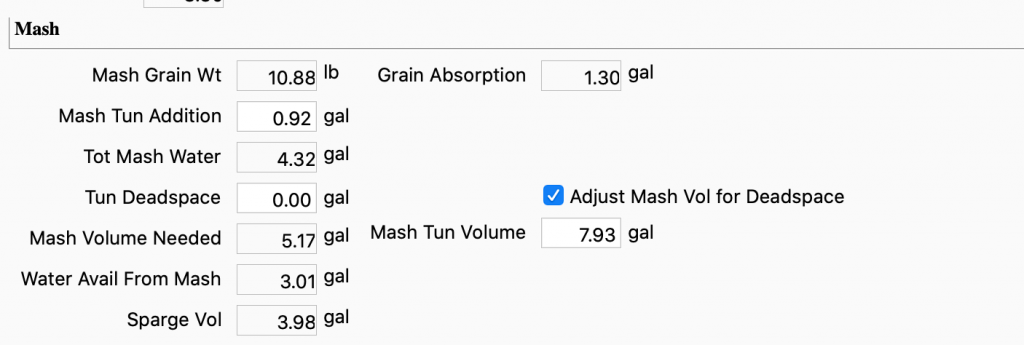

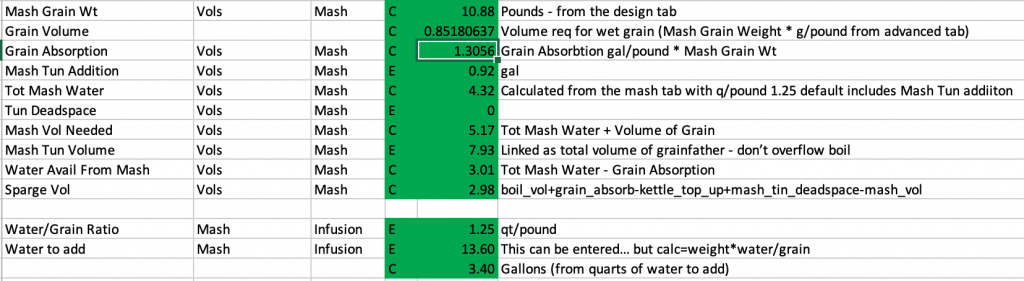

The next section is Mash

The Mash Grain Wt (weight) comes from your recipe.

Grain Absorption = Mash Grain Wt * Grain Absorption (from the advanced options)

The Tot Mash Water comes from the Mash Profile which you set earlier plus the Mash Tun Addition. In this specific case it was calculated with

- 10.88 pounds * 1.25 qts/pound * 1 gallon/4 quarts = 3.4 Gallons + 0.92 Gallons = 4.32 Gallons

The Tun Deadspace is a parameter for you to enter and is the unrecoverable amount of fluid in the mash tun (things below the pickup in the bottom of the Grainfather)

The Mash Volume Needed = Total Mash Water + Volume of the Wet Grain (which isn’t shown on this screen but is on my spreadsheet)

The Volume of the Wet Grain = Grain weight * gallons/pound Remember from the advanced tab which had Grain Volume in litres/pound. This is how much space is taken up inside of your mash tun for wet grain.

Water Available from the Mash = Total Mash Waster – Grain Absorption (this is how much wort can move to the next step)

The Sparge Vol comes from a long chain of calculations on the next sections…

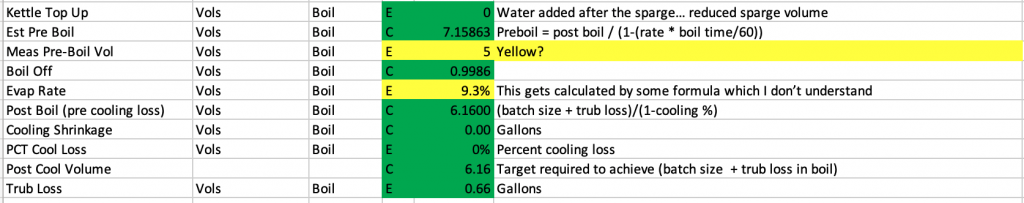

Here is the section of my spreadsheet which represents these calculations.

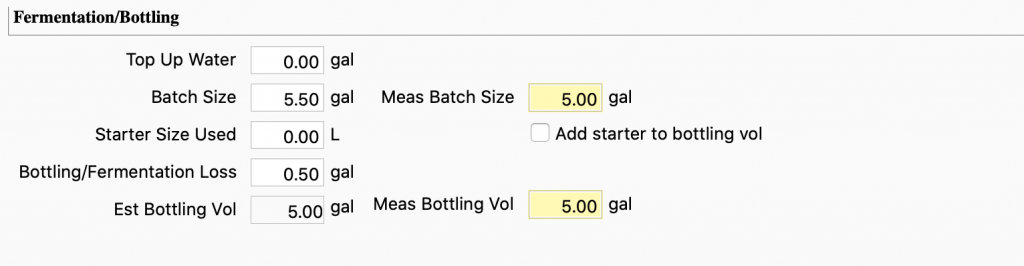

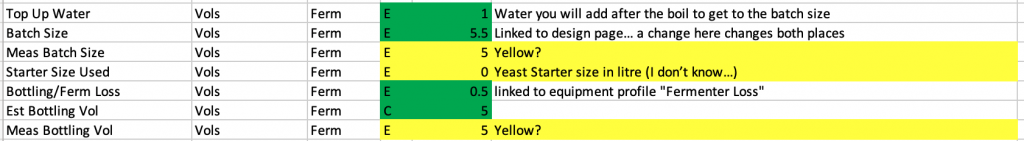

Now I am going to skip the Boil and Fermentation section and come back because the Fermentation/Bottling section uses data from the this section as an Input.

Top Up Water is how much water you add to the boiled wort as you add it into the Fermenter. I am not sure why you would do this, perhaps to lower the gravity?

The Batch Size is a parameter that came from the recipe page and is all over this software. This value is how much wort you are going to put into the fermenter.

The bottling/fermentation loss is how much you loose at the bottom of your fermenter and by taking samples or draining crap during the fermentation process.

I don’t know what “Starter Size Used” is, but I believe that it was put there for a Yeast starter (I have been using Propper Starter). This would add 32 Ozs (aren’t the units fun here) or 0.94 of a liter. On a semi-related note I wonder why they addition of Wort doesn’t change the gravity enough to add into their calculations … I suppose adding 16oz at 1.040 isn’t material. (late edit: I did the math and adding 16oz of 1.040 to a 5.5 gallon batch of 1.060 lower the gravity by 0.04%)

Here is the Fermentation section from my spreadsheet. Notice that in the picture there are two yellow fields for you to override the calculations from that step.

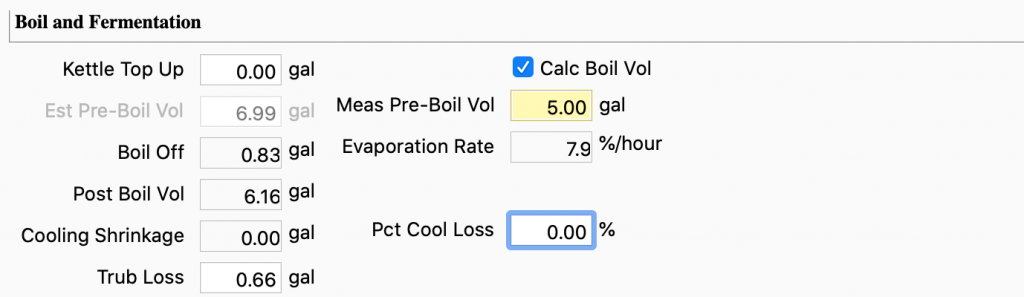

Back to the “Boil and Fermentation” section.

Kettle Top Up is how much water you add before you boil after the mash (I have no idea why you would do this)

The best way to think about the rest of this is to

- Remember that we are trying to back calculate Sparge Water

- Start from the bottom and work back to the top

Trub loss is what it say it is. With this you can now calculate a value which isn’t shown on this screen. I call that value “Post Cool Volume”

Post Cool Volume = Batch Size + Trub Loss – Kettle Top Up

In order to achieve the “Post Cool Volume” you need to increase the work volume by the amount of Cooling Shrinkage.

Pre Cool Volume = Post Boil Volume / (1-Pct Cool Loss)

Cooling Shrinkage = Pre Cool Vol – Post Cool Volume

I suppose that I was surprised that the number was anything other than 0 as I thought that liquids dont change their volume very much. Shows what an electrical engineer knows eh.

Est Pre-Boil Vol = Pre Cool Volume / ( 1 – (Evaporation Rate * Boil Time / 60 Minutes))

With that you can now calculate Boil Off = Pre boil – Post Boil

Finally Sparge Volume = Est Pre Boil – Kettle Top Up + Grain Absorption + Tun Deadspace – Tot Mash Water

Here is my spreadsheet:

Final Thoughts

I have not answered (at least) the following questions

- Where did the Grainfather numbers come from?

- Given (1) why is there a difference between Beer Smith and Grainfather

- What other calculators are out there?

- What is “Batch Sparge Using Batches that fill %” used for?

I am pretty sure that the right thing for me to do next is to design a set of experiments that will arrive at the configuration parameters that best match my setup. I think that it would be useful to describe this procedure.

There may very well be an error in here. In fact I would say with certainty that I made some error. If you have made it this far and you spotted the error I would very much like to know what it is so that I can fix it.

2 Comments

Hi Allen,

I have many of the same questions, including clarity of definitions of inputs and outputs. I am also new to making beer (with GF 30) and collaborating with someone who is using BeerSmith.

So, did you further evaluate / solve the issues you pose?

Would greatly appreciate any sharing you can offer.

Thanks

Paul

I didnt solve them.

I gave up and switched to using Distilled water and adding beer smith specified salts.

Alan